- Product Details

- {{item.text}}

Quick Details

-

Certificate:

-

CE

-

Certification:

-

CE SGS SON ISO9001: 2000

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Transportation:

-

Ocean

-

Certificate:

-

CE

-

Certification:

-

CE SGS SON ISO9001: 2000

| Model | LQJ-III |

Production Specification

I. Function

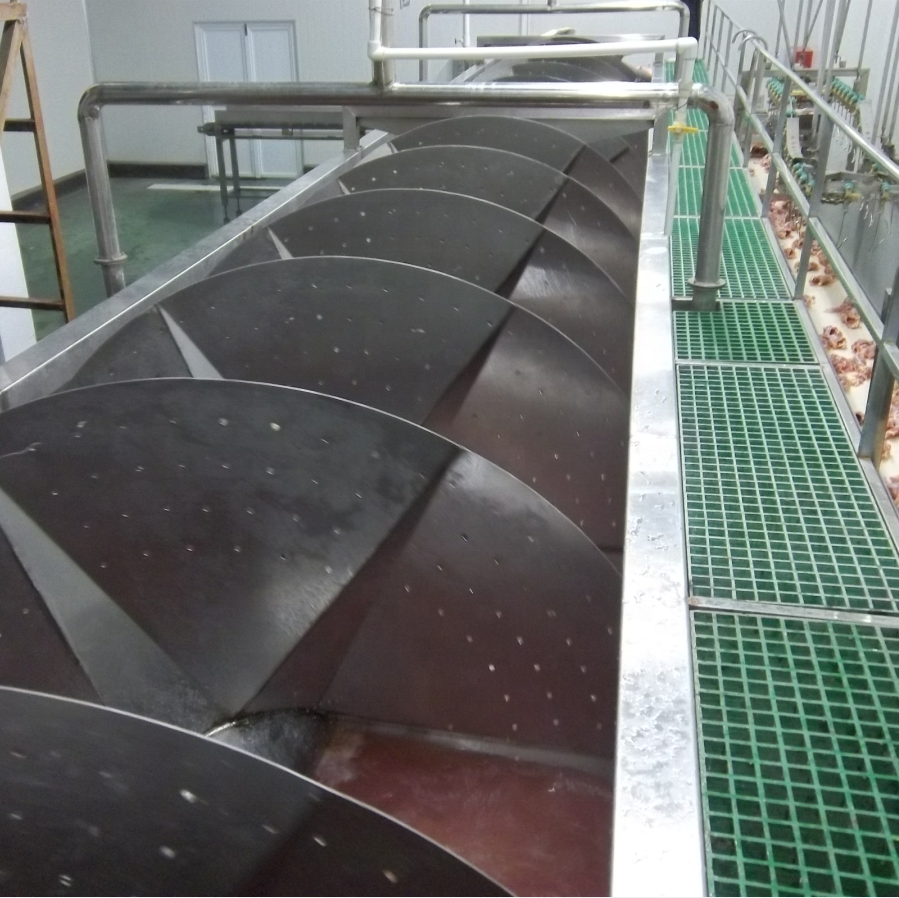

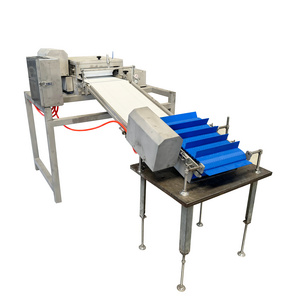

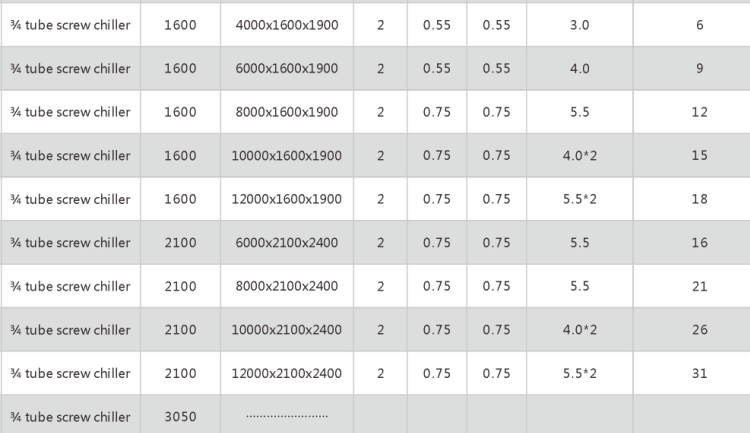

Screw chiller is used for pre-chilling carcass or its by-products during the poultry process. Early 1990s, we first exclusively manufactured this machine after investigate many countries equipment. It win the highly evaluation by users after promotion in China. It have the following special feathers and benefits according to the traditional water tank pre-chilling.

1. Small space needed.

2. Saving energy by small amount of energy loss.

3. Good pre-cooling effect; The traditional water tank pre-chilling which chicken just pass by the tank which hanging on the shackles with the conveyor line, the blood water and blood which in chest and skin is hard to remove out. But the chicken in screw chiller forward by screw blade pushing, and at the same time with the air blow up which by fans to make chicken turns around in the water, which make the blood move out from chest.

4. All build by stainless steel, aesthetic, health, entirely up to international standards.

5.The shaft rotating speed is regulated by converter, which effect control the chilling time.

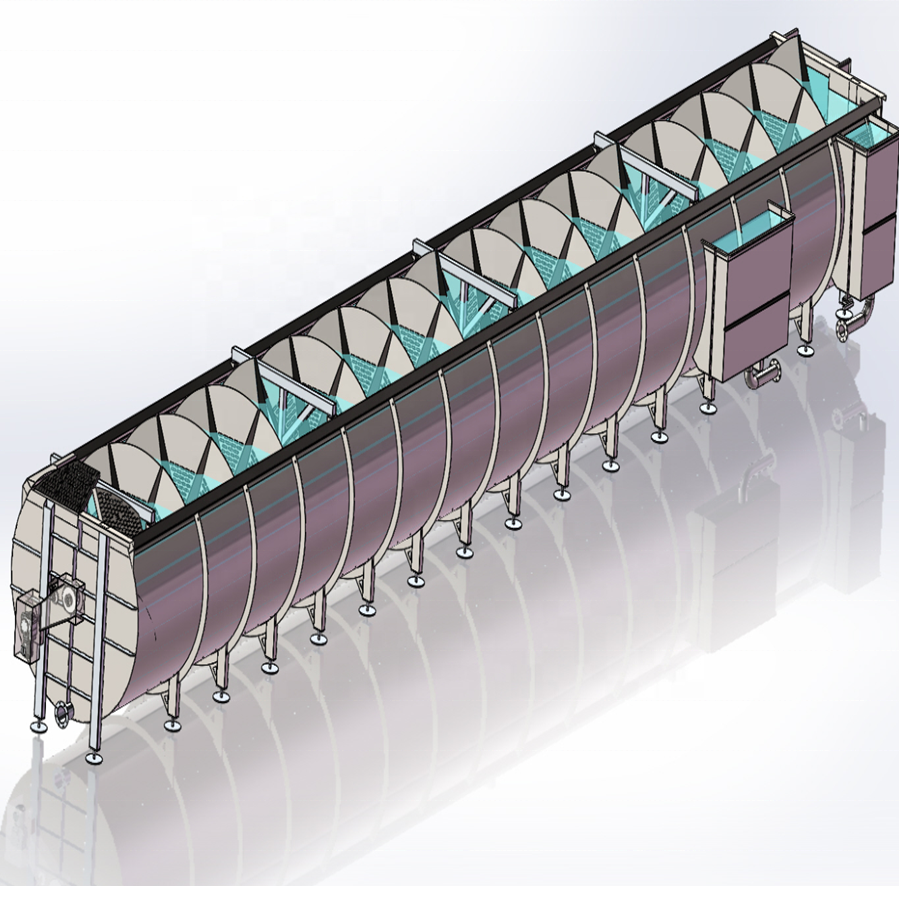

II. The structure and working principle.

The Screw Chilling including two model, one is single-driver, the other is dual driver. The overall equipment including two section which one for washing, the other for chilling. It composed by semi-circular cylinder, screw blade, main shaft, dumper, and driving unit. The working process follow the principle of bird and water fowl reverse, which is after the water filled,

the overflow exit is in front to best washing birds.

Package and Delivery

The fully automatic Poultry Processing Line including

1. live Bird Reception Machine such as live birds crates stack and destack machine, transporting conveyor,crates washer.

2. Poultry Slaughtering Unit of chicken water bath stunner, automatically killing machine, feather plucker, scalder, head cutter or puller, chicken hock cutter, shackle washer and automatic conveyor line transfer to Chicken Evisceration unit .

3. Chicken Evisceration Machine such as opener, vent cutter, eviscerator, cropper, neck breaker, chicken inside and outside washer, and then transfer to Chicken pre-chilling unit of Water chilling or Air Chilling system, if the final product is whole bird will go to packing direct after chilling, if have cut-up parts, will processed by Chicken Cut-Up Machine.

4. the chicken by-prdocuts is processed by its handling equipment , like for gizzards of gizzard de-fatter, peeler, cutter, after packing products will sent it to Chilling room , blast freezer , and transfer to cold room for storage.

The fully automatic poultry processing line equipment

Our Connect