- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

POW-SD-003

-

Product Name:

-

Customized Professional Stamping Die Maker

-

Mould life:

-

300000-500000shots

-

Cavity:

-

Muti Cavity

-

Application:

-

Car and House Application

-

Mould material:

-

Cr12Mov,D2,SKD11,SKH51

-

Surface treatment:

-

Customize

-

Certification:

-

ISO9001:2008

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

POW-SD-003

-

Product Name:

-

Customized Professional Stamping Die Maker

-

Mould life:

-

300000-500000shots

-

Cavity:

-

Muti Cavity

-

Application:

-

Car and House Application

-

Mould material:

-

Cr12Mov,D2,SKD11,SKH51

-

Surface treatment:

-

Customize

-

Certification:

-

ISO9001:2008

China Mold Manufacture made stamping die mould punching mold for Auto Parts

| Product name |

Professional Stamping/Professional Stamping Die /Professional Die |

| Mold shaping | Punching Mold/Stamping Die Mold |

| Mold base | LKM;HASCO;DME,etc |

| Mold material |

Cr12Mov,D2,SKD11,SKH51,etc

|

| Tolerance | +/-0.02-0.05mm |

| Finish | electroplate ,etc |

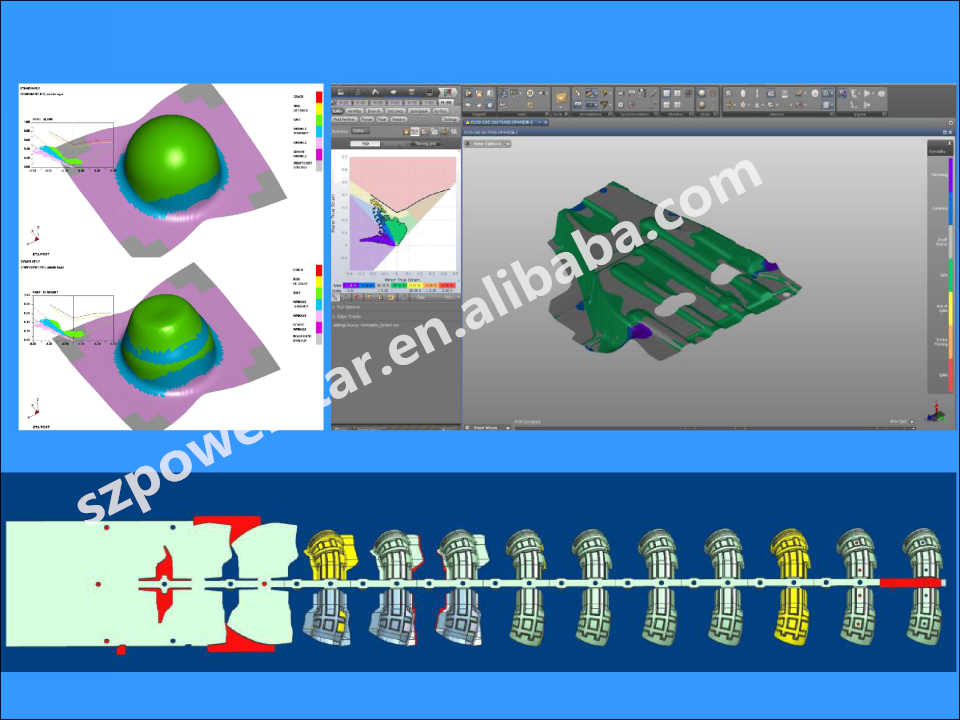

| Design software | VISI,Autoform,UG,Press CAD,etc |

| Product material | Metal |

| Mold life | 300k-500k shots |

| Lead time | 25-45 days |

| Transportation | By sea, by air or by land as you request |

| Package | Standard or as you request |

| OEM/ODM | Acceptable |

| Certificate | ISO9001:1008,SGS, |

What we can do ?

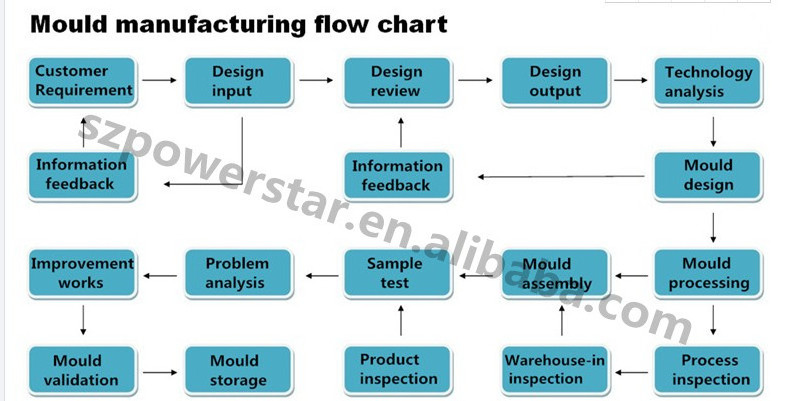

Powerstar concentrates on high quality stamping dies for the world wide customers.As for stamping dies up to 4M in length, from CAE Simulation, 3D layout design, tool structure design and machining. from tool assembly to tool tryout and mass production, all of these operations are carried out within our Powerstar company.

The Product Shown

Stamping Dies Example

Our company

http://www.powerstar-metal.com

Factory

Packing

China Manufacturer Customized design fast precision plastic injection mold

1,Q:How many moulds could you make every month?

A:60-80 sets.

2,Q:How about the largest mould you ever made?

A:15 ton. The size is 1.8m * 1.5m.

3,Q:How about the tolerance?

A:Mould tolerance 0.005mm, Product tolerance 0.01mm.

4,Q:What is percentage of automotive moulds you made? What’s the brand?

A:About 40%. Brand: Volvo, TOYOTA,Land Rover.

5,Q:Can you make precision mould ?

A:Yes. We have made precision moulds such as moulds for medical devices.

6,Q:Can you make BI-injection mould?

A:Yes. And we have made a couple of BI-injection tools.

7,Q:Have you ever made stack mould?

A: Yes.

8,Q:How about the steel you usually use?

A:We only use raw materials with good quality like P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2767, H13,8407, 420SS, S136, S-7. They are all from famous suppliers, such as LKM, ASSAB, THYSSEN, etc. Steel quality certificate and heat-treatment certificate will be provided along with the tools while delivery.

9,Q:What is the standard of your hot-runner system?

A:It’s decided by the customers. We have famous hot runner suppliers locally, such as YUDO, DME, SYNVENTIVE, HASCO,HUSKY, INCOE, EWIKON, MOULD-MASTER etc.

10,Q:What about the standard components you use?

A:We use standard components from LKM,, HASCO, DME, etc.

11,Q:What do you need for quotation? And what about the format?

A:2D & 3D part files are preferred. Or specific sample with detailed description and mould specification. We use PROE, AUTOCAD, Acorbat Reader, Solidworks, UG and etc. All format related are acceptable.

12,Q:How long do you need for quotation?

A:Exact quotation will be available within 2 working days once we get sufficient information from customer.

13,Q:What is your turnround time for injection mould building?

A:Usually 4-8 weeks. It also depends on mould size and structure complexity.

1. Respond as Soon as Possible

2. Keep Clients Updated

3. Go the Extra Mile

4. Fix Your Mistakes

5.24 hours online

6. Keep Promises

7. Don’t Confuse Clients with Jargon

8. Be Patient

9. Know Everything we Need to Know

Contact person:Jenny LO

Tel:86-0755-26586158

Mob: 0086-15999501102 ( WhatsApp &Wechat )

Email:jenny at powerstar-cn.com

Web: http: // www.powerstar-cn.com

Skype:loujiana

Transaction History