- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

qiaogong

-

Dimension(L*W*H):

-

1520*316*216mm

-

Weight:

-

17 KG

-

Core Components:

-

The electromagnetic valve

-

Product Name:

-

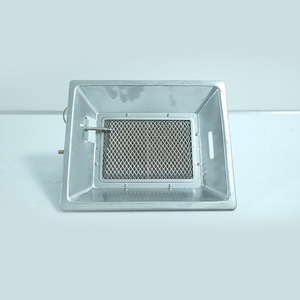

Gas Heater

-

Heater type:

-

Infrared Radiant Heater

-

Power:

-

66W

-

Heat input:

-

29.3kW

-

Fuel:

-

NG LPG

-

NOx:

-

28 mg/m3

-

Heating Mode:

-

Infrared Ceramic Heating

-

Ignition type:

-

electronic

Quick Details

-

Type:

-

Infrared Heater

-

Power Source:

-

Natural Gas

-

Voltage:

-

220V

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

qiaogong

-

Dimension(L*W*H):

-

1520*316*216mm

-

Weight:

-

17 KG

-

Core Components:

-

The electromagnetic valve

-

Product Name:

-

Gas Heater

-

Heater type:

-

Infrared Radiant Heater

-

Power:

-

66W

-

Heat input:

-

29.3kW

-

Fuel:

-

NG LPG

-

NOx:

-

28 mg/m3

-

Heating Mode:

-

Infrared Ceramic Heating

-

Ignition type:

-

electronic

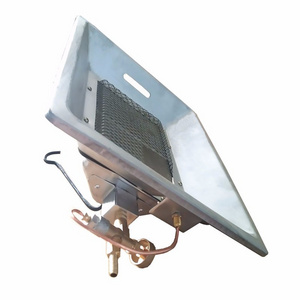

Product Description

It is the most economical choice for any high intensity heater. It delivers uniform and reliable comfort

to industrial and commercial facilities with high ceilings up to 70 feet. Full operating temperature is

reached within 2 minutes making it the ideal choice for supplying total building heat, spot heating, and

work level heating.

The unique ceramic tile design increases radiant efficiency and reduces fuel cost up to 50% over conventional

heating systems and is suitable for industrial and commercial applications.

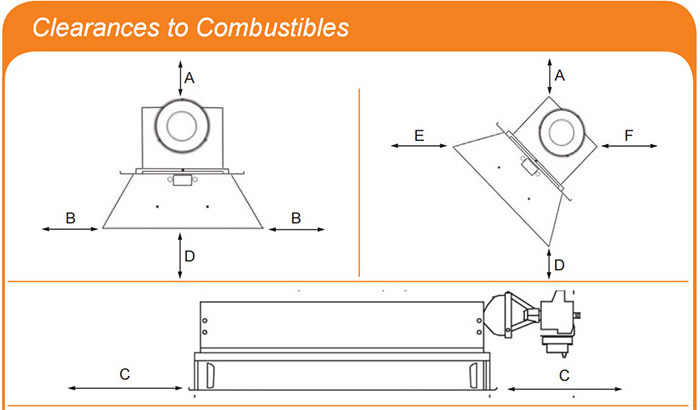

Information below is intended only as a reference and should not be used when installing equipment. Please ensure you locate the most recent instruction manual for accurate and up to date information.

APPLICATION

A gas-fired luminous (high intensity) radiant heater may be installed for heating of commercial /

industrial non-residential spaces.

This heater is not for installation in a Class 1 or Class 2 explosive environment, nor for any residential application. If installation of this equipment is in question, consult with local authorities having jurisdiction (Fire Marshall, labor department, insurance underwriter, or others).

GAS SUPPLY PIPING

A. Gas piping must be sized to provide adequate input capacity to all heaters and appliances

in the system and at the pressure indicated in Table 3 below.

IMPORTANT: Minimum supply line pressure at the inlet to the heater regu

lator must not be lower than 6.0 inches of water column pressure for natu

ral gas and 11” w.c. for propane. The gas supply pressure must be

checked with all heaters in operation.

B. Provide a 1/8 in (3.2 mm) NPT plugged tapping, accessible for test gauge connection, im

mediately upstream of the gas supply connection to the heater.

C. It is recommended to install an approved flexible connector between the heater and gas

piping - available as option from Schwank or from your local supplier.

D. A drip-leg prior to the inlet connection to the heater must be provided in the gas line.

E. On propane-fired units, a main line filter is recommended.

F.

Piping joint compounds must be resistant to the action of natural gas or LPG

G.

TEST FOR LEAKS:

Apply soap suds solution to all connections and joints and if bubbles

appear, leaks have been detected and must be corrected.

DO NOT USE A MATCH OR

OPEN FLAME OF ANY KIND TO TEST FOR LEAKS. NEVER OPERATE THE HEATER

WITH LEAKING CONNECTIONS

. Leak test according to local or national codes.

DO NOT

use pressure greater than 1/2 psig to pressure check the heater.

The supply system should be checked first with heater turned “OFF” followed by another

check with heater turned “ON”.

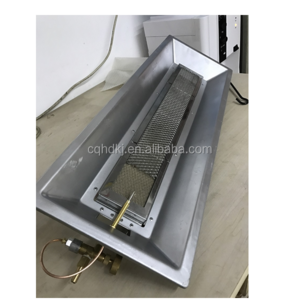

Product features

Stainless steel

burner housing to resist corrosion and withstand high temperature

Green technology: fuel costs and CO2 emissions reduced up to 50%

Direct spark ignition ensures ultimate safety and fuel economy

Parameters

| Model | Heat input(kW) | NOx (mg/m3) | Standard gas flow rate(NG)(m3/h) | Standard gas flow rate(LPG)(kg/h) | Gas pipe diameter |

Power (W) |

Voltage (V~) |

Frequency (Hz) |

Dimensions (L×W×H) (mm) |

| FQT(Y)GZ30 | 29.3 | 28 | 2.9 | 2.47 | DN20 | 66 | 220 | 50 | 1520×318×216 |

1kW=860kcal

The calorific value of natural gas is 8900 kcal/Nm³; the calorific value of LPG is 11000 kcal/kg.

Standard pressure of gas supply: Natural gas is 2.0 kPa,LPG is 5.0 kPa

Allowable range of gas supply pressure: natural gas 1.5~3.5 kPa, LPG 2.8~5.5 kPa

Hot Searches