- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHARE

-

Voltage:

-

380v 50Hz 3 phases (customizable)

-

Dimension(L*W*H):

-

4800*1300*1500mm

-

Weight:

-

1500 kg

-

Name:

-

single layer corrugated roll forming machinery roof sheet corrugated

-

Keywords:

-

roof roll forming machine

-

Kw:

-

roll forming machine profile

-

Control way:

-

Automatic PLC control

-

frame structure:

-

250 h steel

-

Thickness of equipment medium plate:

-

11 rows

-

Molding shaft material:

-

45# steel

-

Key words:

-

roof panel roll forming machine

-

Keyword:

-

metal roof roll forming machine

-

Product name:

-

roof sheet roll forming machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze

-

Production Capacity:

-

8-10m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHARE

-

Voltage:

-

380v 50Hz 3 phases (customizable)

-

Dimension(L*W*H):

-

4800*1300*1500mm

-

Weight:

-

1500 kg

-

Name:

-

single layer corrugated roll forming machinery roof sheet corrugated

-

Keywords:

-

roof roll forming machine

-

Kw:

-

roll forming machine profile

-

Control way:

-

Automatic PLC control

-

frame structure:

-

250 h steel

-

Thickness of equipment medium plate:

-

11 rows

-

Molding shaft material:

-

45# steel

-

Key words:

-

roof panel roll forming machine

-

Keyword:

-

metal roof roll forming machine

-

Product name:

-

roof sheet roll forming machine

Products Description

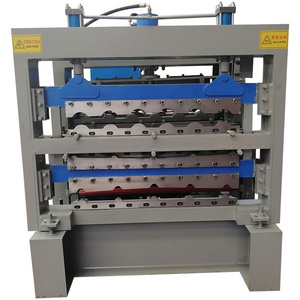

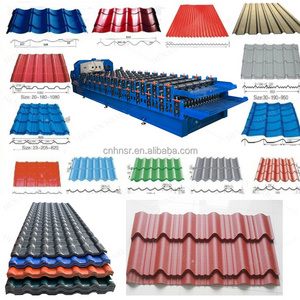

Share Single Layer Corrugated Roll Forming Machinery Manufacturers Tile Zinc Roof Sheet Corrugated Roll Forming Machine

1.

Fully Automatic Control System with PLC.

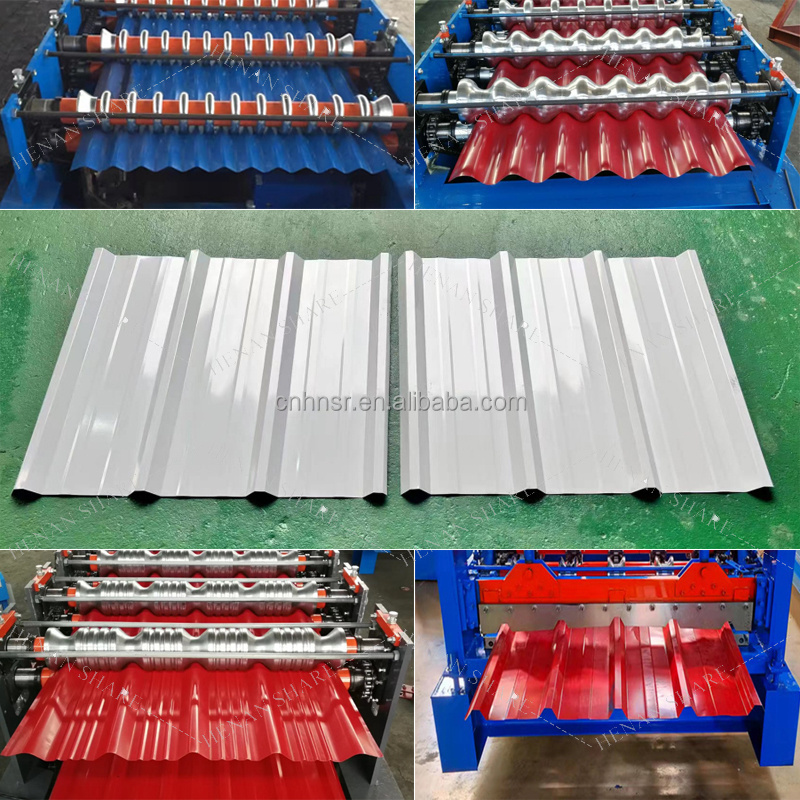

2. This roll forming machine can roll form metal roofing sheet. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface.

3. Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

4. Easy operation: Key in the length and quantity on the control panel.

5. We also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing.

3. Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

4. Easy operation: Key in the length and quantity on the control panel.

5. We also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing.

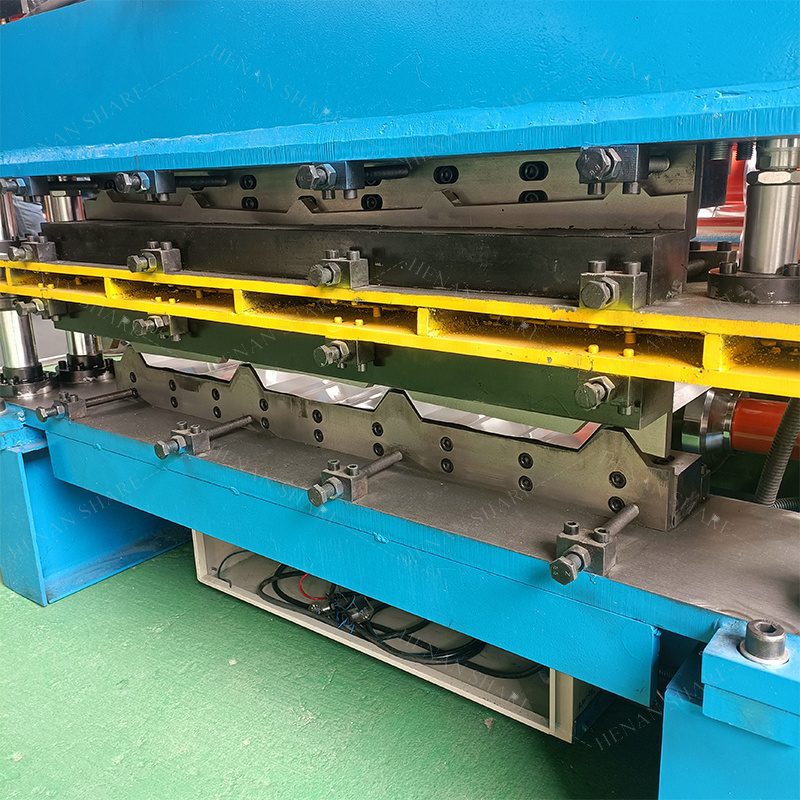

Details Images

|

Model

|

SRYWJ-1200GP

|

|

Voltage

|

380v,50hz, 3 phases(customizable)

|

|

Feeding width

|

1200MM

|

|

Effective width

|

1000MM

|

|

Thickness

|

0.3-0.8MM

|

|

Roller material

|

45# steel plated with chrome

|

|

Diameter of shaft

|

70MM

|

|

Roller station

|

16MM

|

|

Main motor power

|

5.5kw

|

|

Hydraulic station power

|

4kw

|

|

Control system

|

PLC

|

|

Number of rolling molding rows

|

11 rows(According to different types request different)

|

|

Weight

|

1500kgs

|

|

Dimension

|

4800*1300*1500mm

|

Product packaging

Directly load in containers.

Hot Searches