Suitable for welding the sink within the range of 1600x700x300mm. (customized)

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HWASHI

-

Voltage:

-

Three-phase 380V±10% 50Hz, customized according customer's requirement

-

Dimension(L*W*H):

-

2000mmx1800mmx2100m

-

Weight (KG):

-

600

-

Power (kW):

-

100

-

Machine type:

-

160KVA Stainless Steel Circular Seam Welding Machines for Sink Tank

-

Power:

-

160 KVA

-

Heat Adjustment Range:

-

15%-99%

-

Diameter of Welding Wheel:

-

100 - 120 mm

-

Max.Secondary Floating Voltage:

-

9.5 V AC

-

Weight:

-

200kg

-

Service life:

-

8-10 year

-

Certification:

-

CE ISO CCC

Quick Details

-

Wheel Size(mm):

-

customized

-

Year:

-

Custom models

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HWASHI

-

Voltage:

-

Three-phase 380V±10% 50Hz, customized according customer's requirement

-

Dimension(L*W*H):

-

2000mmx1800mmx2100m

-

Weight (KG):

-

600

-

Power (kW):

-

100

-

Machine type:

-

160KVA Stainless Steel Circular Seam Welding Machines for Sink Tank

-

Power:

-

160 KVA

-

Heat Adjustment Range:

-

15%-99%

-

Diameter of Welding Wheel:

-

100 - 120 mm

-

Max.Secondary Floating Voltage:

-

9.5 V AC

-

Weight:

-

200kg

-

Service life:

-

8-10 year

-

Certification:

-

CE ISO CCC

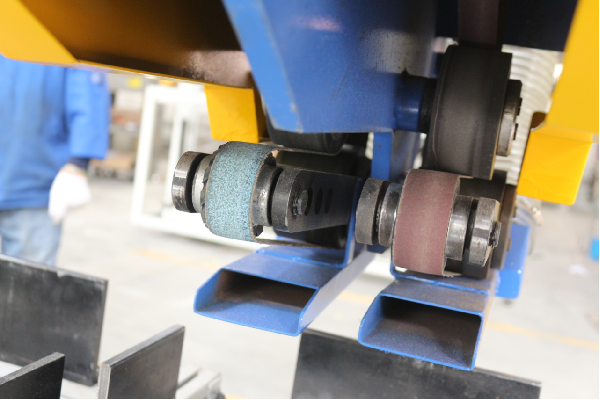

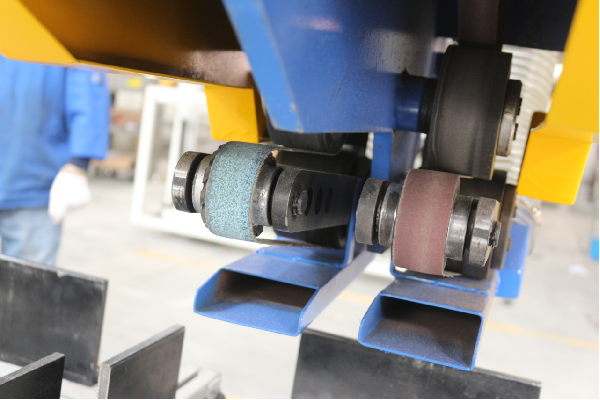

HWASHI Sink Edge round corner grinding machine

CNC 3 Axis Control Stainless Steel Kitchen Sink Edge Grinding and Polishing Machine utilizes abrasive belt polishing principle. The abrasive belt is driven by electric motor to conduct polishing on the edge of the welded sink. There are two processes for polishing. Firstly, use the coarse abrasive belt to grind the redundant cutting edge and the projection welding spots. Then use the fine abrasive belt to conduct polishing treatment. After these two processes can meet the requirement of sink grinding and polishing treatment. It is designed to use Mitsubishi professional automatic control system. You only need to input the coordinate data of the product and start the machine, the abrasive belt of the machine will conduct grinding and polishing automatically within the track of preset program. The worker only needs to put and take out the sink.

Special Design Grinding Belt

Brown belt (fine abrasive belt) DEERFOS RA631 150#

Blue belt (coarse abrasive belt) 577F P80Y

The movement and control system will be the same as the sink seam welding machine

Auto Moving Table and Fixture Structure

For sink bowl within 1500mm, we can choose to use fixed table with adjustable fixture. For sink bowl over the limit, we can design the automatic moving feeder to achieve full automatic grinding and polishing.

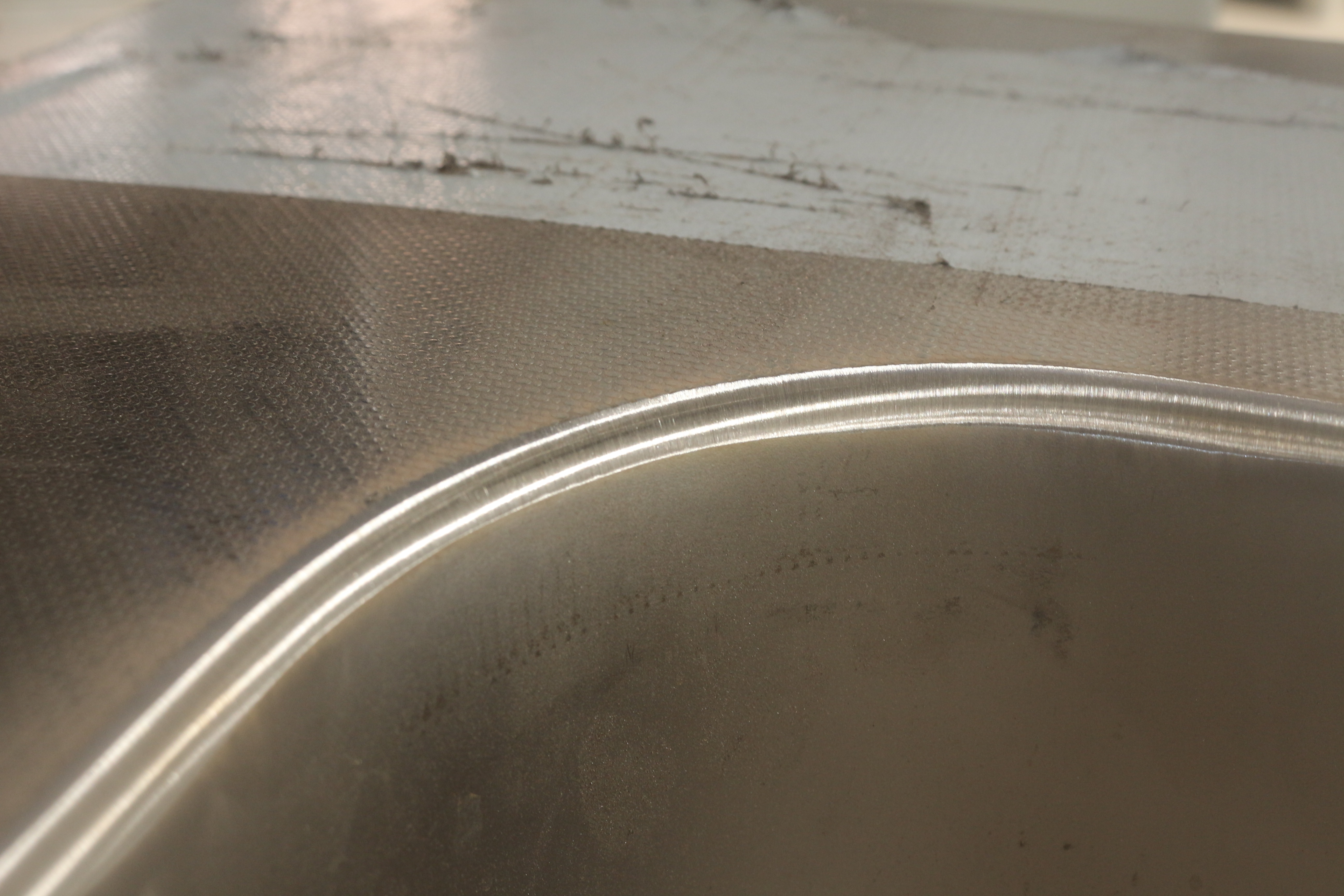

R-Corner Polishing Effect

Straight Seam Polishing Effect

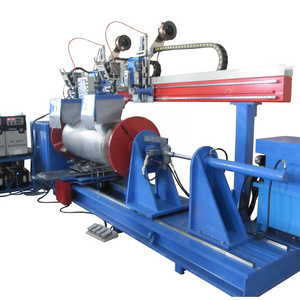

CNC 3 Axis Stainless Steel Sink Seam Welding Machine

CNC 3 Axis Control Stainless Steel Kitchen Sink Seam Welding Machine is a method that uses a pair of roller electrodes instead of the cylindrical electrodes of spot welding, and the welded workpiece moves between the rollers to produce a sealed weld with a molten core overlapping each other to weld the workpiece together.

Adopt medium frequency inverter power source of welding and large flat platform of locating method. Use the servo motor to drive X axis (locating mould) and Y axis (welding electrode) to operate under the preset procedure of PLC data. According to the stored position of welding spot, the welding product will be located inside the mould and moves horizontally along the X direction. The welding electrode will be designed to move vertically along the Y direction. The welding electrode is able to conduct 360° of rotation under the control of servo motor so it is suitable for welding different angles of products.

Japan Mitsubishi CNC Control System

Adopts three sets of Japan Mitsubishi servo motor to control axis X (movement of sink mould), axis Y (vertical movement of welding wheel), and axis A (360° rotation of welding wheel).

MF DC Welding Controller

Be able to save 32 types different welding models for different material and thickness.

Big Copper Flat Table Electrode and Fixture

We will design the fixture according to the design of your sink bowl. Different sizes may require different fixtures. Be able to do welding of single bowl, double-bowl, or three-bowl product.

Stock Machine Available

We have sufficient machines in stock, we can deliver the machines to you within 20 days. Only need to prepare the customized fixture for you. Welding Test is available.

Specification

|

CNC Sink Seam Welding Machine

|

Model

|

WL-AMF-160K

|

|

|

Input Power (V/φ)

|

380V 3φ

|

|

|

Rated Power (KVA)

|

160/250KVA (as per material thickness)

|

|

|

Applicable Material

|

Stainless Steel 304/201

|

|

|

Material Thickness

|

0.8~1.5mm (customized)

|

|

|

Effective Welding Length

|

1600-3000mm (customized)

|

|

|

Effective Welding Width

|

600-800mm (customized)

|

|

|

Sink Bowl Shape

|

Square/Rectangular/Round

|

|

|

Welding Efficiency

|

about 40-60sec/bowl (depend on the size of bowl)

|

|

CNC Sink Edge Grinding and Polishing Machine |

Max. Moving Speed

|

500mm/sec

|

|

|

Belt Rotation Speed

|

1200R/min

|

|

|

Min. Radius

|

R40

|

|

|

Rated Air Pressure

|

0.6MPa

|

|

|

Grinding Efficiency

|

about 60-80sec/bowl (depend on the size of bowl)

|

Application and samples

We can provide customized service for you. Our engineers will discuss the specific welding requirement with you and come out withthe suitable technical proposal based on your samples or drawings.

Factory & Certificate

HWASHI

22

years+ experience welding solutions expert

Guangdong Hwashi Technology Inc. which was established in 2001, is located in Huizhou, Guangdong province in China. We are the high-tech enterprise which is specialized in developing, manufacturing, and selling of resistance welding machine, automatic welding machine and industrial robot station. We have total two manufacturing plants covering an area about 60000 square meters.There are about 200 staffs in Hwashi, and among which there are more than 20 mechanical and electrical engineers. Most of our engineers got more than 10 years experience in welding industry. Until now, we got more than 70 patents regarding the welding machine projects. Our machines have been exported to more than 70 counrties in the world. And we have local distributor in Russia, Turkey, Romania, Saudi Arabia, Malaysia, Indonesia, India, and USA, etc. who will provide you professional pre-sales and after-sales service in local.

Certifications

We have passed the international certifications such as

CE

certification,

ISO 9001

quality management system certification, Alibaba enterprise certification and design patents.

After-sales service & Customer visiting

1.spot welding machine

1 years warranty

except consumable parts

2.Plenty of technical support

online

is available

3.Quick Back-up Parts Available&Technical Assistance

4.

"Training Video","Instruction Book",

and

"Operation Manual"

will be offered

Packing & Delivery

Acceptable Delivery Terms

EXW, FOB, C&F, CIF, DDU, DDP

Quality Control

Strictly control all aspects of incoming materials, processing, assembly, commissioning, testing, packaging and shipping to ensure the performance and quality of welding products.

Professional Package

1. Whole film packaging machine;

2. Anti-collision package edge;

3. Wooden box and pallets with iron binding belt.

Service Team& feedback

Professional Team

Over the years, Hwashi has cultivated a large number of talented, dedicated and innovative Hwashi people. We have a professional team of experts with rich experience in electrical engineering, mechanical design and welding technology.

Since its establishment

22

years

ago, hwashi technology has traveled to all corners of the world, participated in more than

100

exhibitions

and served more than

8,000

customers

FAQ

Q1: What is the price of your machine?

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us the following information.

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us the following information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable

technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary,visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable

technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary,visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

Hot Searches