- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

K813, K1014, K1214, Promass

-

Product Name:

-

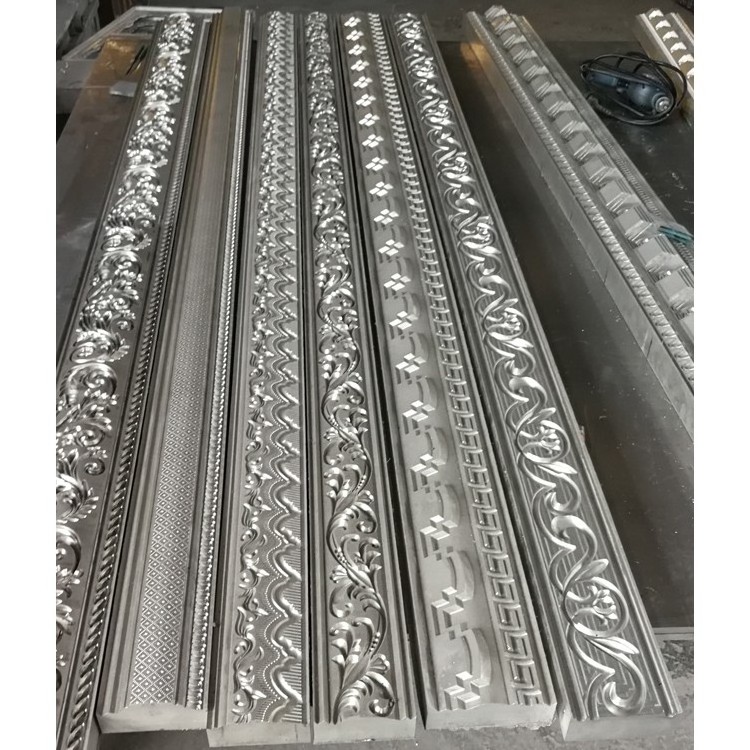

Cornice Expanded Polystyrene Mold

-

Making process:

-

CNC making Cornice Expandable Polystyrene Mould

-

Application:

-

Package, Inner Parts, Boxes, ICF, Decoration Products, Car Parts, etc

-

Design software:

-

CAD, IGS, STTP etc.Cornice Polystyrene Mold

-

Mould Frame:

-

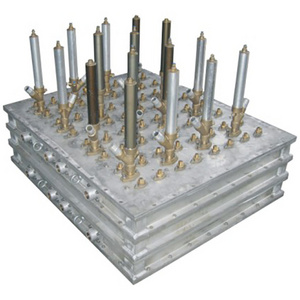

Standard Steam Chamber with Cooling System

-

Certification:

-

CE, ISO 9001Cornice Styrofoam Mould

-

Mould life:

-

5 years to 10 years

-

Our Customers/Market:

-

USA, Canada, Mexico, Vietnam, Brazil

-

Product Type:

-

Styrofoam Mold, Polystyrene Mold, Tool

Quick Details

-

Shaping Mode:

-

Vacuum casting/Die casting

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Milon

-

Model Number:

-

K813, K1014, K1214, Promass

-

Product Name:

-

Cornice Expanded Polystyrene Mold

-

Making process:

-

CNC making Cornice Expandable Polystyrene Mould

-

Application:

-

Package, Inner Parts, Boxes, ICF, Decoration Products, Car Parts, etc

-

Design software:

-

CAD, IGS, STTP etc.Cornice Polystyrene Mold

-

Mould Frame:

-

Standard Steam Chamber with Cooling System

-

Certification:

-

CE, ISO 9001Cornice Styrofoam Mould

-

Mould life:

-

5 years to 10 years

-

Our Customers/Market:

-

USA, Canada, Mexico, Vietnam, Brazil

-

Product Type:

-

Styrofoam Mold, Polystyrene Mold, Tool

Product Description

Detailed Images

Related Products

Auto Pre-expander

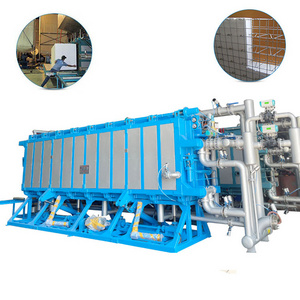

Auto Shape Moulding Machine

Accessories

Hot Searches