- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

50 KG

-

Marketing Type:

-

Hot product

-

Product Name:

-

100l 200l 500l Micro brewery Draft Beer Brewing Equipment

-

Application:

-

Restaurants

-

Function:

-

Making Beer

-

Material:

-

SUS 304 superior stainless steel, red copper cladding

-

Heating method:

-

Electric Heating Steam Heating

-

Control system:

-

PID

-

Cooling way:

-

Dimple Plate Cooling

-

Cleaning way:

-

CIP Cleaning Ball

-

Thickness:

-

Inner 3mm External 2mm

-

Cooling Jacket:

-

Glycol Cooling Jackt

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

50 KG

-

Marketing Type:

-

Hot product

-

Product Name:

-

100l 200l 500l Micro brewery Draft Beer Brewing Equipment

-

Application:

-

Restaurants

-

Function:

-

Making Beer

-

Material:

-

SUS 304 superior stainless steel, red copper cladding

-

Heating method:

-

Electric Heating Steam Heating

-

Control system:

-

PID

-

Cooling way:

-

Dimple Plate Cooling

-

Cleaning way:

-

CIP Cleaning Ball

-

Thickness:

-

Inner 3mm External 2mm

-

Cooling Jacket:

-

Glycol Cooling Jackt

500l pilot brewery 1000 l brewing system micro beer equipment beer making machine pub all in one brewing system

Introduction:

Whether you’re a beer lover or not, you’re probably aware of the sweeping craft beer movement that has taken our country by storm. Craft beer has been growing rapidly over the past few years,

and production growth for craft beer is far outpacing overall beer production.

According to the Brewer Association Craft beer must be small, independent and traditional.

- “Small” means the brewery distributes no more than six million barrels of beer a year.

- “Independent” means that less than 25 percent of the brewery is owned by a non-craft beer brewery (like Anheuser-Busch InBev).

- “Traditional” means that the majority of the brewery’s output consists of “beers whose flavor derives from traditional or innovative brewing ingredients and their fermentation.”

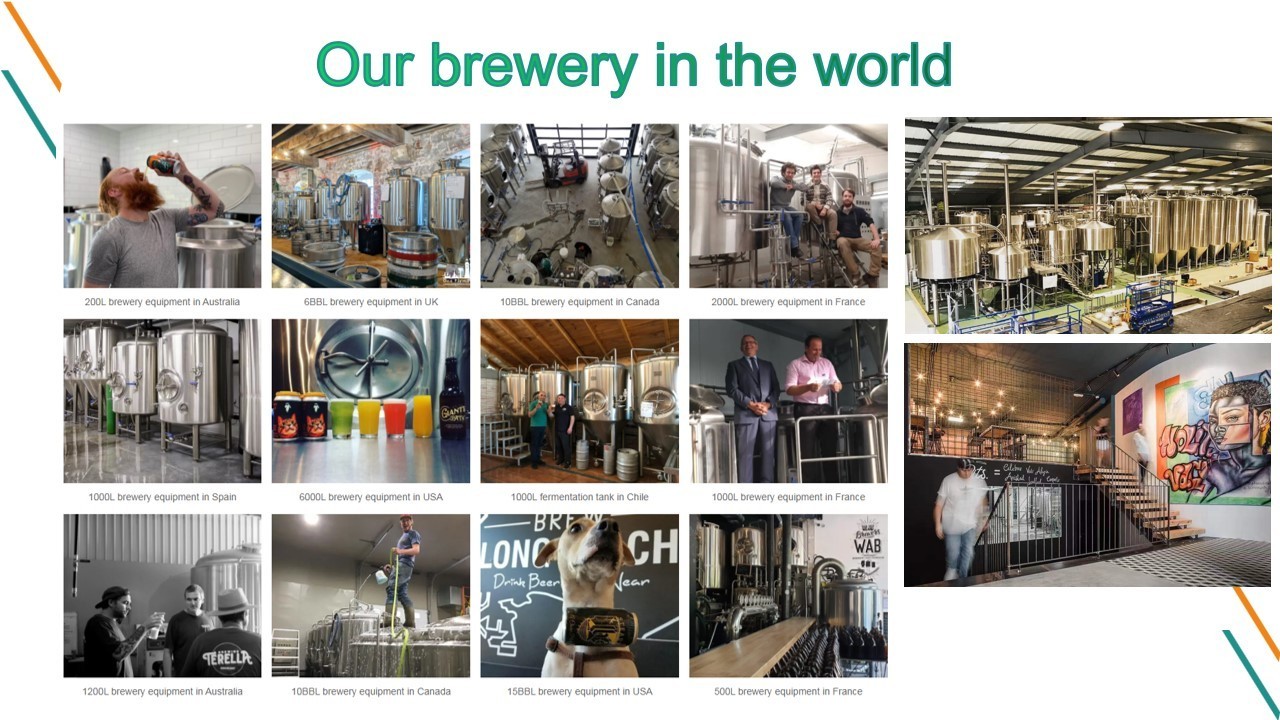

Are you looking forward to building your own dream craft brewery??

Zhihua Beer Equipment company will be your reliable partner.

How big beer brewing systm are you looking for?

Specifications

|

Output/Brew |

10HL (Mash/Lauter, Kettle/Whirlpool) Plus one 10HL Hot Water Tank |

|

Brew/Week |

6~12 Batches |

|

Output/Week |

60~120HL |

|

Electric Supply |

3phase/380(220, 415,440…)v/50 (60)Hz

|

|

Heating Source |

Steam/Directly Fired |

|

Area Request |

>70M2 |

|

Brewmaster |

1 |

Note: 1hl=100liter; 1Gallon=3.7854liter; 1Barrel (BBL) =117Liter;

2Vessels Brewhouse: Mash/Lauter, Kettle/Whirlpool tun plus Hot Water Tank

3Vessels Brewhouse: Mash/Lauter, Kettle/Whirlpool tun

2Vessels or 3vessls Brewhouse?? This is a question for many new breweries.

Actually it depends on the daily brew you are requireing and also how much installation space you have.

If you are planning to brew double batches per day to maximize the brewhouse function, 3vessels is OK.

There is various combination for 3vessels brewhouse like:

A: Mash/Lauter tun, Kettle tun, Whirlpool tun

B: Mash/Kettle tun, Lauter tun, Whirlpool tun

C: Mash tun, Lauter tun, Kettle/Whirlpool tun

1----Mill System

Capacity: 100kg/h, 300kg/h, 500kg/h, 800kg/h, 1000kg/h.

Description: CE or UL listed Motor, Double roller, distance adjustable, stainelss steel 304 material.

Optional: Flexible Auger.

2----Brew House System

-Two-Four vessles or combined system.

-Capacity 100L-5000L, 1bbl-40bbl.

- Steam heated, electrical heated or natural gas

-Mash tun with mixer, steam jacket, VFD motor, insulated 80mm. Stainelsss steel 304.

-Lauter tun with rake system, milled false bottom, sparging spray ring,VFD motor, insulated 80mm.

-Boiling kettle with steam jacket, inner heated option, insulated 80mm. Stainelsss steel 304.

-Whirlpool with Tangential whirlpool inlet. insulated 80mm. Stainelsss steel 304.

-Insulated HLT and CLT with the pipelines and pumps

-External grant, hops back, heat exchanger.Wort oxygenation system, working platform.

-All the necessary pipelines and pumps.

3----Fermenter&BBT System

-Capacity: 100L-30000L, 1bbl-100bbl, +25% Head space

-Interior shell thickness 3-6mm, Exterior shell=2mm

-100% TIG welding with pure argon gas shield

-Interior finish: pickled and passivated, external polished, 80mm insulated

-Test pressure 3 bar, working pressure 1.5 bar

-Glycol zones (Both on side and concial/bottom)

-60°conical bottom for Fermener, Shadow less side man way

-Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

-Mechanical relief valve 3 bar on CIP arm with pressure gauge

-Adjustable tank leveling pads

4----Cooling System

Description: Air type chiller + Ice water tank or Glycol tank

Capacity: 3HP, 5HP, 7HP, 10HP, 15HP, 20HP, 30HP+ 500L-20000L tank

Brand: Copeland, SANYO.

5----Control System

-PID or PLC system

-SIEMENS program S7-200, Siemens touch screen.

-Penumatic valves for optional

6----Canning line, Kegging line

-Double station Kegging line.

-Small capacity Canning line.

Small Parts to serve for Brewhouse unit

Whole SUS Manhole

Sample Valve

Grist Hydrator

SUS304 Agitator & Spray Ring Ball

Beer Fermentation Tank

There is single-batch Fermentation tank and double-batch Fermentation tank to match Brewouse.

For example 1000L FV and 2000L FV is both OK to be partner with 1000L brewhouse.

The amounts of Fermentation tank directly affect theweekly or monthly beer output.

All details are taken the humanized and brewmasters’ intention into consideration.

Reliable quality is guaranteed by professional technical support, advanced processing equipment,

strict quality control and complete personnel training. Insisting the idea that craft beer brewing should be in a popular style,

we always keep our Products affordable which may help more brew masters to approach their dream.

Join Zhihua and start your beer brewing career!