Commonly used for measuring the thickness of anodized layers on various aluminum components and protective coatings on PCB.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LS225+N1500

-

Material:

-

Plastic

-

Item Weight:

-

194

-

Accuracy:

-

≤±(2%H+0.3μm), ≤±(2%H+0.3μm) after 5 points calibration

-

Product name:

-

LS225 coating thickness gauge

-

Measuring principle:

-

Eddy current

-

Substrate:

-

Non-ferromagnetic metal

-

Measuring range:

-

0.0-1500μm

-

Resolution:

-

0.1μm: 0-99.9μm 1μm: 100-999μm 0.01mm: 1.00-1.50mm

-

Repeatability:

-

≤ ± (0.8%H+0.1μm) Test with fixture

-

Unit:

-

μm / mil

-

Measuring interval:

-

0.8s

-

Minimum measuring area:

-

7mm

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Linshang

-

Model Number:

-

LS225+N1500

-

Material:

-

Plastic

-

Item Weight:

-

194

-

Accuracy:

-

≤±(2%H+0.3μm), ≤±(2%H+0.3μm) after 5 points calibration

-

Product name:

-

LS225 coating thickness gauge

-

Measuring principle:

-

Eddy current

-

Substrate:

-

Non-ferromagnetic metal

-

Measuring range:

-

0.0-1500μm

-

Resolution:

-

0.1μm: 0-99.9μm 1μm: 100-999μm 0.01mm: 1.00-1.50mm

-

Repeatability:

-

≤ ± (0.8%H+0.1μm) Test with fixture

-

Unit:

-

μm / mil

-

Measuring interval:

-

0.8s

-

Minimum measuring area:

-

7mm

Related Products

Product Description

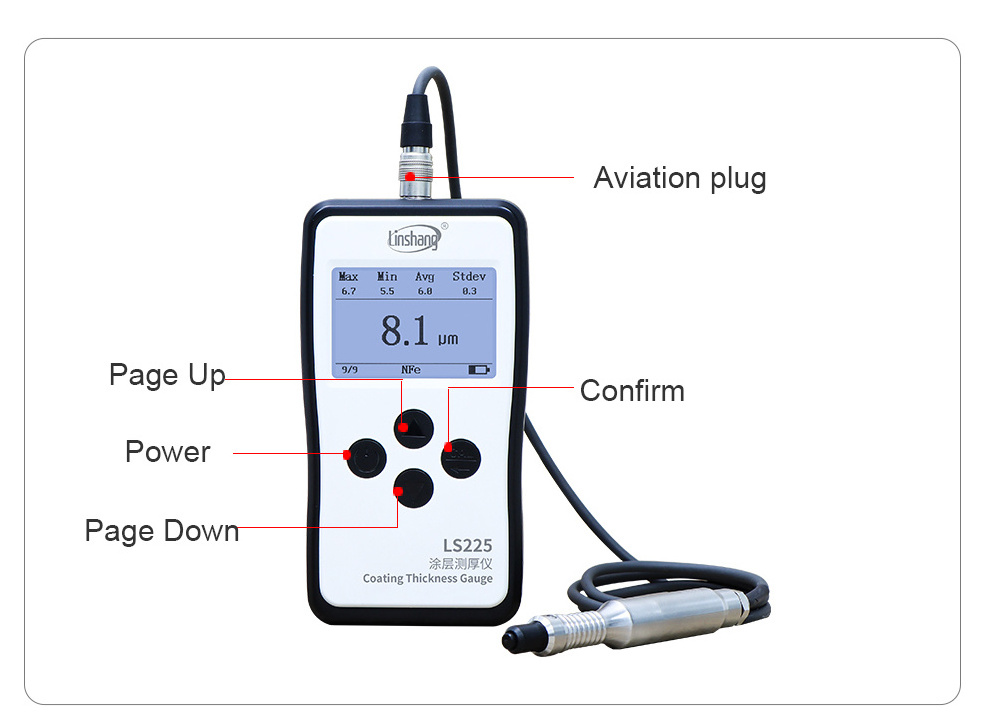

LS225 N1500 Eddy Current Effect Coating Thickness Gauge High Precision Powder NFe Measurement Device Coating Thickness Meter

LS225+N1500

coating thickness gauge

is a portable, split-type eddy current thickness gauge consisting of LS225 host and the non-ferrous probe N1500. With a probe-style design, it's ideal for measuring coating thickness on small-sized workpieces and irregular materials. For measuring ultra-thin coatings below 10μm, it's recommended to use LS225+N1500

coating thickness meter

with a test fixture for a repeatability of 0.1μm. The LS225+N1500

eddy current effect coating thickness gauge

is capable of quick, non-destructive measurements of non-conductive coatings on non-ferrous metal substrates, such as anodized layers on various aluminum components or protective coatings on PCB surfaces.

Features:

1. Accurately and consistently obtain data for coatings with thicknesses below 10μm.

2. The probe's minimum measurement area is 7 mm, making it suitable for testing small-sized materials.

3. Utilizing cutting-edge digital probes guarantees precise test results.

4. Featuring data statistics, LS225 calculates maximum, minimum, average, and standard deviation values.

5. It facilitates zero adjustment and multi-point calibration for enhanced data precision.

6. The option of dedicated fixtures minimizes error sources, achieving data repeatability up to 0.1μm.

7. The coating thickness meter ensures it can pass tests by authoritative metrology institutes.

2. The probe's minimum measurement area is 7 mm, making it suitable for testing small-sized materials.

3. Utilizing cutting-edge digital probes guarantees precise test results.

4. Featuring data statistics, LS225 calculates maximum, minimum, average, and standard deviation values.

5. It facilitates zero adjustment and multi-point calibration for enhanced data precision.

6. The option of dedicated fixtures minimizes error sources, achieving data repeatability up to 0.1μm.

7. The coating thickness meter ensures it can pass tests by authoritative metrology institutes.

Specifications

|

LS225 plating thickness gauge host parameters

|

|

|

|

Parameter

|

Value

|

|

|

Display

|

240×160 dot matrix LCD

|

|

|

Power supply

|

4pcs of 1.5V AAA alkaline battery

|

|

|

Operation temperaturerange

|

0℃-50℃

|

|

|

Storage temperaturerange

|

-20℃-60℃

|

|

|

Host size

|

148*76*26 mm (L*W*H)

|

|

|

Weight (include battery)

|

194g

|

|

|

N1500 probe parameters

|

|

|

|

Parameter

|

Value

|

|

|

Measuring principle

|

Eddy current

|

|

|

Substrate

|

Non-ferromagnetic metal

|

|

|

Measuring range

|

0.0-1500μm

|

|

|

Resolution

|

0.1μm: 0μm - 99.9μm

1μm: 100μm - 999μm

0.01mm: 1.00mm – 1.50mm

|

|

|

Repeatability

|

≤ ± (0.8%H+0.1μm) Test with fixture, H is the standard value

|

|

|

Accuracy

|

≤±(2%H+0.3μm) after 5 points calibration, H is the standard value

|

|

|

Unit

|

μm / mil

|

|

|

Measuring interval

|

0.8s

|

|

|

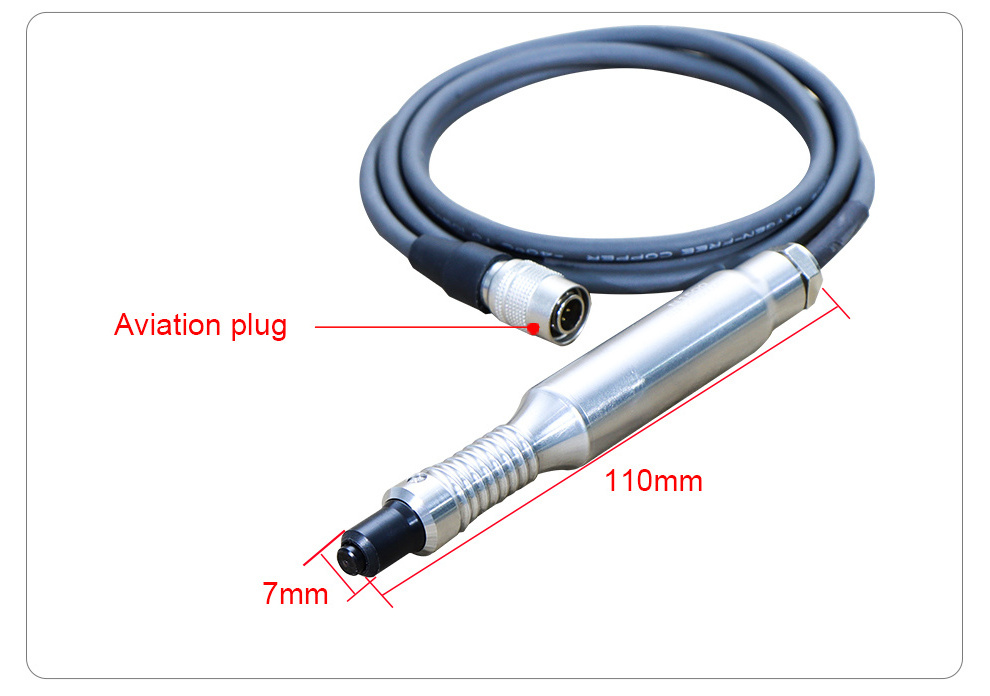

Minimum measuring area

|

Ø = 7mm

|

|

|

Minimum curvature

|

Convex:1.5mm / Concave:10mm

|

|

|

Minimum substrate thickness

|

0.05mm

|

|

|

Calibration

|

Support zero reference adjustment and 1 to 5-points calibration

|

|

|

Probe size

|

110*15 mm (Without connecting cable)

|

|

|

Probe weight

|

81g

|

|

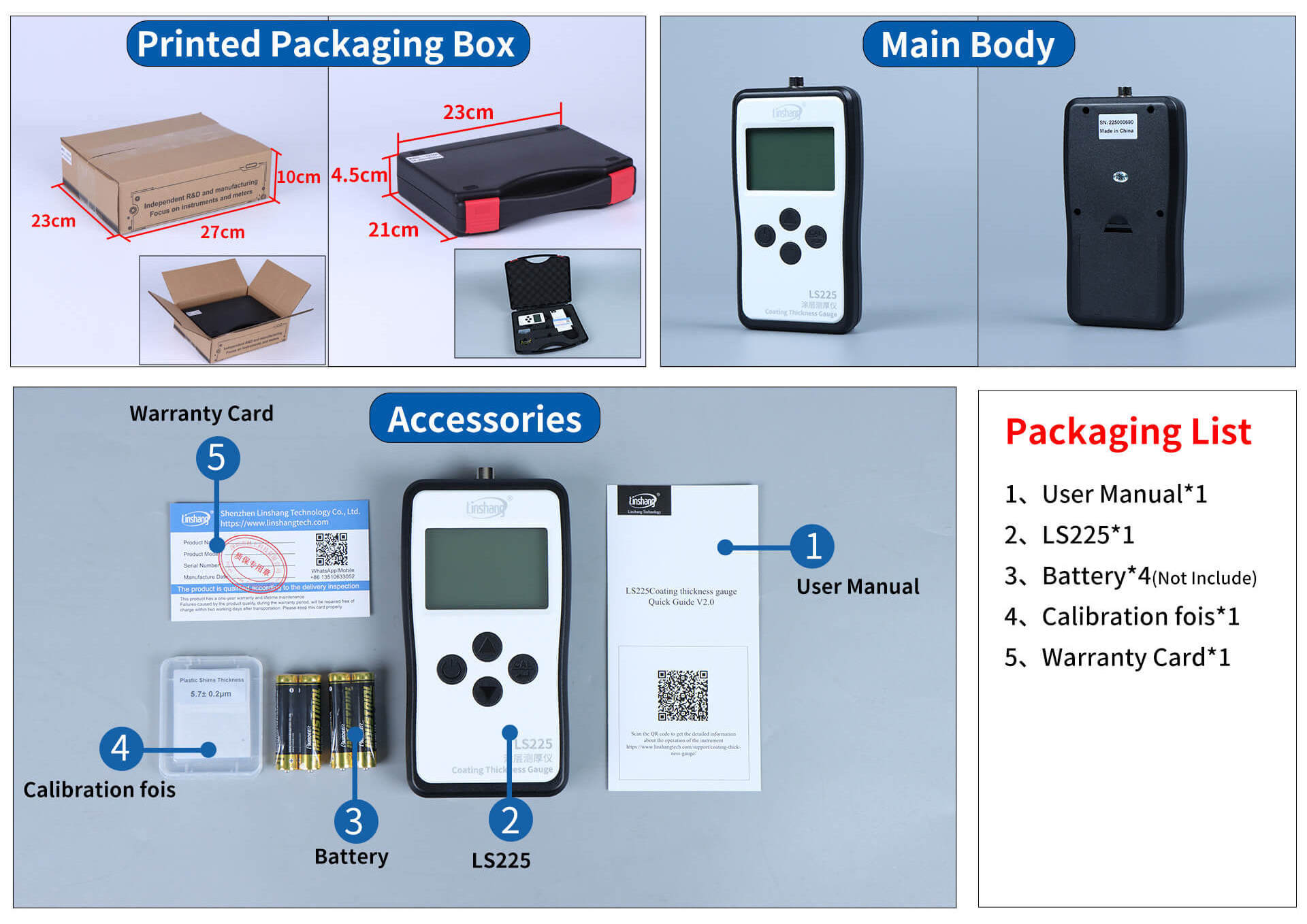

Structure & Packing

|

No.

|

Description

|

Quantity

|

Unit

|

|

1

|

LS225 Plating thickness tester

|

1

|

Set

|

|

2

|

N1500 probe

|

1

|

Pcs

|

|

3

|

NFe zero-adjustment plate

|

1

|

Pcs

|

|

4

|

Standard films

|

1

|

Pcs

|

|

5

|

User manual

|

1

|

Pcs

|

|

6

|

Certificate / Warranty card

|

1

|

Pcs

|

|

7

|

Plastic engineering case

|

1

|

Pcs

|

Note

If you need to buy the fixture stand, please contact us!

Versatile applications

Measuring extremely thin coatings

Perform accurate and stable

coating thickness measurements

of coatings below 10μm in thickness.

Measuring compact and irregular materials

The probe's minimum measuring area of 7 mm is ideal for testing small-sized workpieces and shaped materials.

Enable multi-point calibration

The thickness gauge powder coating

enables both zero adjustment and multi-point calibration to enhance data precision.

Statistics function

With statistics function, LS225

eddy current effect coating thickness gauge

can automatically calculate the maximum, minimum, average and the standard deviation.

Choose dedicated stable fixtures

Selecting dedicated stable fixtures can eliminate errors and achieve data repeatability as precise as 0.1μm.

Certified by authoritative metrology institute

The

coating thickness meter

ensures it can pass tests by authoritative metrology institutes.

Transaction & Client

Delivery

|

Packing

|

Air Carton / Express Packaging / Shrink Package

|

|

Delivery Terms

|

EXW, DAP, Express Delivery

|

|

Delivery Time

|

5-10 days in stock

|

|

Port

|

Shenzhen

|

FAQ

1. How long is the product guarantee?

2. What materials can be tested with Linshang coating thickness gauge?

The Linshang coating thickness gauge uses both the Hall Effect and the eddy current principle. It is an iron-aluminum dual-use instrument that automatically recognizes the substrate and switches between iron-based and non-ferrous-based measurement modes.

It is also suitable for measuring non-conductive coatings (coatings, anodized layers) on non-magnetic metal substrates such as copper,aluminum,die-cast zinc,etc.

3. The difference between LS225 and other coating thickness gauges

4. What are the similarities and differences between LS221 and LS223?

The same point: the probes of the LS221 and LS223 coating thickness gauges are connected to the main unit through an external line, which can measure some small spaces and higher or lower positions. The reading is more convenient.

Difference: The LS223 also supports automatic trigger boot during the test. The LS221 coating thickness gauge does not have this function.

5. Do I need to calibrate the instrument before I use it?

No, Linshang coating thickness gauge does not require calibration and can be used only by making zero adjustment.

6. In what conditions do we need to make zero adjustment?

Several situations in which zero adjustment is recommended before testing:

Tested material substrate has been changed

The instrument has not been used for a long time

When the ambient temperature changes greatl

The instrument has been replaced with a battery

7. Does Linshang coating thickness gauge provide a measurement certificate?

The Linshang coating thickness gauge can ensure the inspection by the authoritative metrology institute. If you need a metrology certificate, you can send it to a third-party authoritative metrology institute for inspection. Our company also provides the inspection service on behalf of the company. After the completion of the inspection, the metrology institute will inform you of the payment.

8. Do you offer OEM and ODM service?

Yes. We can supply OEM and make customized design for any specific application.

9. Who are we?

10. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

11. What can you buy from us?

Colorimeter,Gloss meter,Coating thickness meter,window tint meter,UV meter, Leeb hardness tester, Ultrasonic thickness gauge.

12. Why should you buy from us not from other suppliers?

Shenzhen Linshang Technology Co., Ltd. was established on June 16, 2008. The company adheres to independent design, research and development, production and sales of various measuring instruments.

13. What services can we provide?

Accepted Delivery Terms: EXW,DAP;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,Western Union;

Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, French, Russian, Korean, Italian.

14. Does the instrument have a warranty?

Guarantee period is 12 months, after the warranty, we also provide life-long paid or service.

15. Do you offer samples to buy?

Yes, you are welcome to order samples to experience our excellent quality and service.

16. Can you offer quality certification?

17. Do you have after-sales service?

Yes, our instrument have professional After-sales Dept. lf you have any technical problem or question with our goods welcome to contact us.

Linshang coating thickness gauge can be returned to the factory without any reason in 90days (No human damage and can be used for second sales).The supplier provide one year warranty and lifetime maintenance after-sales service.

2. What materials can be tested with Linshang coating thickness gauge?

The Linshang coating thickness gauge uses both the Hall Effect and the eddy current principle. It is an iron-aluminum dual-use instrument that automatically recognizes the substrate and switches between iron-based and non-ferrous-based measurement modes.

It is suitable for measuring the thickness of non-magnetic coating ( paint, varnish, enamel, galvanized) on magnetic metal

substrates such as steel, iron, etc.,

It is also suitable for measuring non-conductive coatings (coatings, anodized layers) on non-magnetic metal substrates such as copper,aluminum,die-cast zinc,etc.

3. The difference between LS225 and other coating thickness gauges

Compared with several other coating thickness gauges, LS225 has higher measurement accuracy and data repeatability. With a special test fixture, it can be used to accurately measure ultra-thin coatings below 10μm, small size and special-shaped workpieces. It supports zero adjustment and multi-point calibration. The measurement results can be more accurate after calibration through standard films or uncoated workpieces.

4. What are the similarities and differences between LS221 and LS223?

The same point: the probes of the LS221 and LS223 coating thickness gauges are connected to the main unit through an external line, which can measure some small spaces and higher or lower positions. The reading is more convenient.

Difference: The LS223 also supports automatic trigger boot during the test. The LS221 coating thickness gauge does not have this function.

5. Do I need to calibrate the instrument before I use it?

No, Linshang coating thickness gauge does not require calibration and can be used only by making zero adjustment.

6. In what conditions do we need to make zero adjustment?

Several situations in which zero adjustment is recommended before testing:

Tested material substrate has been changed

The instrument has not been used for a long time

When the ambient temperature changes greatl

The instrument has been replaced with a battery

7. Does Linshang coating thickness gauge provide a measurement certificate?

The Linshang coating thickness gauge can ensure the inspection by the authoritative metrology institute. If you need a metrology certificate, you can send it to a third-party authoritative metrology institute for inspection. Our company also provides the inspection service on behalf of the company. After the completion of the inspection, the metrology institute will inform you of the payment.

8. Do you offer OEM and ODM service?

Yes. We can supply OEM and make customized design for any specific application.

9. Who are we?

We are based in Guangdong, China, start from 2008,sell to Domestic Market(60.00%), Eastern Europe(6.00%), Eastern Asia(6.00%), South Asia(5.00%), Mid East(4.00%), Southern Europe(3.00%), North America(3.00%), Western Europe(3.00%), South America(2.00%), Northern Europe(2.00%), Central America(2.00%), Southeast Asia(2.00%), Africa(1.00%), Oceania(1.00%). There are total about 51-100 people in our office.

10. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

11. What can you buy from us?

Colorimeter,Gloss meter,Coating thickness meter,window tint meter,UV meter, Leeb hardness tester, Ultrasonic thickness gauge.

12. Why should you buy from us not from other suppliers?

Shenzhen Linshang Technology Co., Ltd. was established on June 16, 2008. The company adheres to independent design, research and development, production and sales of various measuring instruments.

13. What services can we provide?

Accepted Delivery Terms: EXW,DAP;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,Western Union;

Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, French, Russian, Korean, Italian.

14. Does the instrument have a warranty?

Guarantee period is 12 months, after the warranty, we also provide life-long paid or service.

15. Do you offer samples to buy?

Yes, you are welcome to order samples to experience our excellent quality and service.

16. Can you offer quality certification?

Yes, we can offer quality certification issued by our lab free of charge, or issued by third-party international inspection Organizations with extra charge, please contact us for confirmation.

17. Do you have after-sales service?

Yes, our instrument have professional After-sales Dept. lf you have any technical problem or question with our goods welcome to contact us.

Hot Searches