High precision Panasonic PLC ensure high stably performance and precisely AB glue output quantity

- Product Details

- {{item.text}}

Quick Details

-

Keywors:

-

Engineers available to service machinery overseas

-

A:B Ratio:

-

1:1 - 10:1 optional

-

Three Axis Working Area:

-

700*700*80mm or customized

-

Mixing Method::

-

Static / Dynamix optional

-

Metering Pump:

-

Gear Pump or D&H patented Plunger Pump

-

Output speed:

-

5-66g/5s adjustable

-

Precision:

-

+/-1%

-

Tank capacity:

-

Tank A 25L, Tank B 10L or customized

-

Dimension:

-

1500x1200x500mm

-

delivery time:

-

7 days

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

D&H

-

Weight (KG):

-

450

-

Keywors:

-

Engineers available to service machinery overseas

-

A:B Ratio:

-

1:1 - 10:1 optional

-

Three Axis Working Area:

-

700*700*80mm or customized

-

Mixing Method::

-

Static / Dynamix optional

-

Metering Pump:

-

Gear Pump or D&H patented Plunger Pump

-

Output speed:

-

5-66g/5s adjustable

-

Precision:

-

+/-1%

-

Tank capacity:

-

Tank A 25L, Tank B 10L or customized

-

Dimension:

-

1500x1200x500mm

-

delivery time:

-

7 days

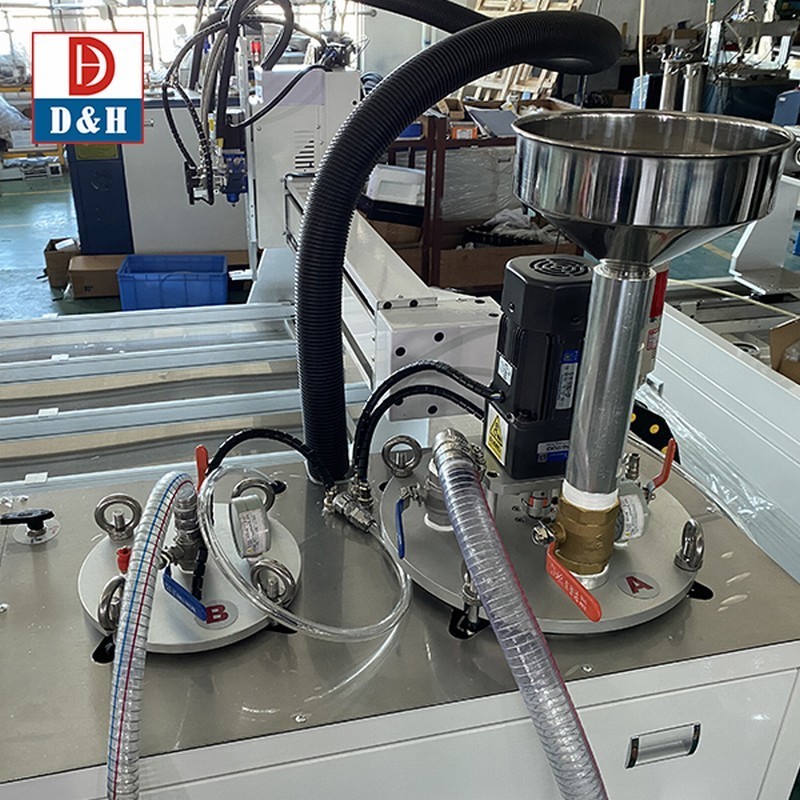

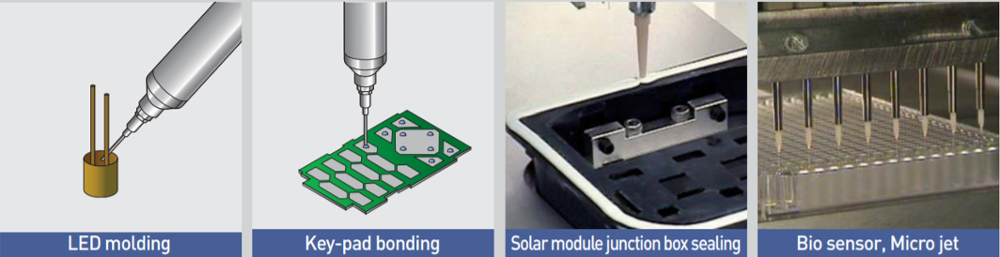

2 part epoxy silicone polyurethane auto glue dispenser auto glue potting machine

2K AB glue potting silicone epoxy pu glue dispensing dispenser

and even high abrasive for thermal conductivity.

Potting and encapsulation is the process of embedding electronic components & assemblies in a liquid resin (potting compounds) toprotect them against rough environment conditions. Potting can be performed in atmosphere pressure or even under vacuum, if high voltage insulation and high temperature differences are needed. Encapsulation of parts will stop corrosion of metals and reduce damage caused by vibration and mechanical stress.

We offer automatic and se-mi automatic fluid dispensing potting machine AB glue dispensing machine Epoxy dispensing machine Two-component dispensing machine Dual-component dispensing machine Meter-mix

dispensing machine Resin dispensing machine Adhesive dispensing system Dispensing robot Dispensing valve Liquid dispenser Automated dispensing equipment

What is the difference between 2K AB adhesive materials manual potting machine and robot potting machine?

2. High precision pump metering system

3. Dynamic/Static mixing system

4. Three-axis motion system

5. Programming control system.

These machines offer a range of benefits for businesses in various industries. First and foremost, they allow for precise mixing of two-component adhesives, eliminating the need for manual mixing and reducing the risk of human error. This ensures consistent quality in your products and reduces waste, saving you time and money in the long run.

In addition, the machines are designed for easy operation and maintenance, with user-friendly interfaces and accessible components. This means that even operators without extensive technical knowledge can use and maintain the machines with ease.

Moreover, the machines come in a variety of sizes and configurations, making them suitable for various production volumes and adhesive types. Whether you need a small machine for occasional use or a large machine for continuous production, there's an AB meter mix machine or two-component glue dispensing machine to fit your needs.

Finally, these machines can also improve workplace safety. By automating the mixing and dispensing process, they reduce the risk

of operator exposure to potentially hazardous chemicals. This ensures a safer working environment for your employees and reduces

the risk of workplace accidents.

In conclusion, the AB meter mix machine and the two-component glue dispensing machine are powerful tools for improving the accuracy, efficiency, and safety of your production process. By investing in one of these machines, you can reduce waste, improve product quality, and streamline your operations. So why wait? Start exploring your options today and take your production process to the next level!

Epoxy PU silicone two parts glue manual dispensing machine 2K AB glue potting silicone epoxy pu glue dispensing dispenser

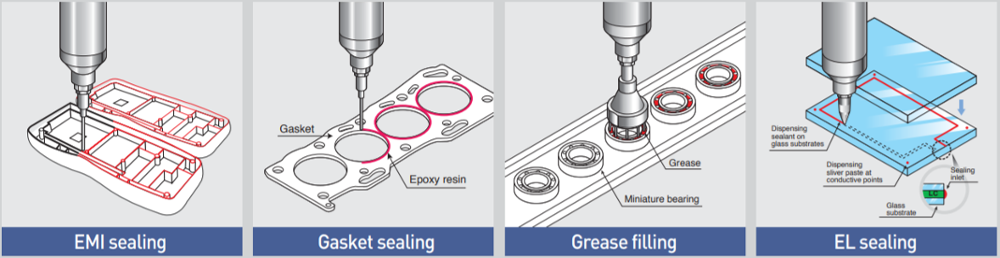

PGB-700 system accurately meters, mixes and dispenses two-component medium to low-viscosity materials for potting, gasketing, sealing, encapsulation and syringe filling. For variable ratio dispensing, the system handles ratios from 1:1 to 10:1.

The system is composed of material tank, metering pump, metering motor, material pipe, two component valve, motor for dynamic stirring and mixing tube. Two kinds of glue are separated before they mix in mixing tube, so the glue will not cure in devices. Glue valve is with vacuum function to keep thin fluid from dripping. Other optional functions include:

Tank stirring function; Tank defoaming function; Thermostat heating function on Tank, pipe, and pump;

2 Part Silicone plyurethane epoxy potting dispensing machine

AB Resins compound dosing , dispensing ,potting system ,2K potting technology AB glue dispensing machine Epoxy dispensing machine

Two-component dispensing machine,Dual-component dispensing machine

Meter-mix dispensing machine,Resin dispensing machine

Adhesive dispensing system,Dispensing robot with high precision Dispensing valve, Liquid dispenser , Automated dispensing equipment

|

Specification Epoxy PU silicone two parts glue manual dispensing machine

|

|

|

|

|||

|

Mixing Method:

|

Dynamic or Static, optional;

|

|

|

|||

|

Repeatability:

|

±1%

|

|

|

|||

|

Mixing Accuracy:

|

±1%

|

|

|

|||

|

Tank Capacity:

|

10L/25L/40L/60L or Customized

|

|

|

|||

|

Mixing Ratio:

|

1:1 - 1:10 adjustable

|

|

|

|||

|

Gluing Speed:

|

5-66g/5s adjustable;

|

|

|

|||

|

Air Pressure:

|

0.5-0.7Mpa

|

|

|

|||

|

Power Input:

|

AC220V 50-60Hz or Customized

|

|

|

|||

|

Dimension:

|

1500*1200*1500mm

|

|

|

|||

|

Weight:

|

260KGS

|

|

|

|||

Machine features:

1. Automatic metering and mixing, touch screen PLC control system, English operation interface allow easy to set parameters;

2. Big LCD screen displays various processing data;

3. Easy programming of dots, stripes, arcs, compound arcs and patterns on different planes;

4. Gluing speed and timing can be set;

5. CAD file can be imported and turned to be dispensing patterns, and downloaded via USB; (optional function)

6. Mixing ratio 1:1-1:10 and gluing volume can be set and adjusted as per actual need. Dynamic mixing ensure two component glue to be mixed to a fully homogeneous consistency;

7. Metering, mixing and gluing simultaneously;

8. Two tanks keep A glue and B glue separately;

9. Liquid level sensor, alarm function;

10. Tank stirring and vacuum defoaming function optional;

11. Auto cleaning; The cleaning mode can be manually or automatically, manual mode just remove the mixing tube then soak into cleaning agent, after 10 min take out and clean with compressed air, Automatic mode only need to operate the cleaning switch on touch screen within 1 minute to complete;

12. Glue tank/metering pump/glue pipe heating function (optional);

13. Vacuum control keeps thin fluids from dripping;

14. Unique control system which will not influenced by air pressure factor, ensures optimal dispensing performance;

* Auto feeding :take use of vacuum pressure to feed materials into A&B tank separately.

* Tank Stirring :A and B tank configure with stirring motors and blades to prevent material sediment in the tank bottom .

* Heating : Tank , pipe , pumps are optional with heaters to assure the whole system can be heating from room temperature to 90°C

adjustable.

* Vacuum : A &B tank vacuum for degas the bubble inside material .

* Dynamic mixing : Configuring dynamic motor and mixer to mix A and B fluids evenly.

Two component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on .

Panasonic PLC.

Dynamic mixing.

High speed mixing motor, mixing glue well. According to glue features, static mixing is available

Vacuum tank with stirring motor.

With defoaming function and mixing motor, no bubbles in glue, pre-heating is available for selection

Tank with liquid sensor.

Both AB tank with high level and low level liquid sensor, when the glue is not enough or the machine is abnormal, the machine will show the warning message. Humanized engineering design, avoid the serious damages. There's a professional sealing ring to make sure the glue tank in vacuum status. To avoid the glue to be crystallization or curved.

Vacuum tank.

vacuum tank with auto glue filling function

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Packaging

|

|

|

|

Size

|

150CM(L) * 110CM (W) * 170CM (D)

|

|

|

Weight

|

550KGS

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). The wooden box will be fumigated. We will use pe film for packing or pack it according to customers special request.

|

|

PJL-1500

Automatic glue mixing machine, manual glue dispenser

PGB-1200

automatic Glue dispensing machine with working area: L1200mm*W1200mm*H80mm

PJL-1200

Automatic glue mixing machine, manual glue dispenser, with long pipe