- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

100%

-

Voltage:

-

110/220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

1400*1600*1800mm

-

Weight:

-

450 KG

-

Production Capacity:

-

>800 pieces/hour

-

Filling Volume:

-

0.5 ml-50 ml

-

Auto Filling System:

-

Servo Type

-

Machine Voltage:

-

110/220/380V

-

Air supply:

-

0.6-0.8 Mpa

-

Auto Capping System:

-

Servo Type

-

Power:

-

2KW

-

Filling Error:

-

≤±1%

-

Material:

-

SUS304/316

Quick Details

-

Machinery Capacity:

-

10-60 bottles per min

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Liquid, Liquid Lotion Cream and so on

-

Filling Accuracy:

-

100%

-

Voltage:

-

110/220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

1400*1600*1800mm

-

Weight:

-

450 KG

-

Production Capacity:

-

>800 pieces/hour

-

Filling Volume:

-

0.5 ml-50 ml

-

Auto Filling System:

-

Servo Type

-

Machine Voltage:

-

110/220/380V

-

Air supply:

-

0.6-0.8 Mpa

-

Auto Capping System:

-

Servo Type

-

Power:

-

2KW

-

Filling Error:

-

≤±1%

-

Material:

-

SUS304/316

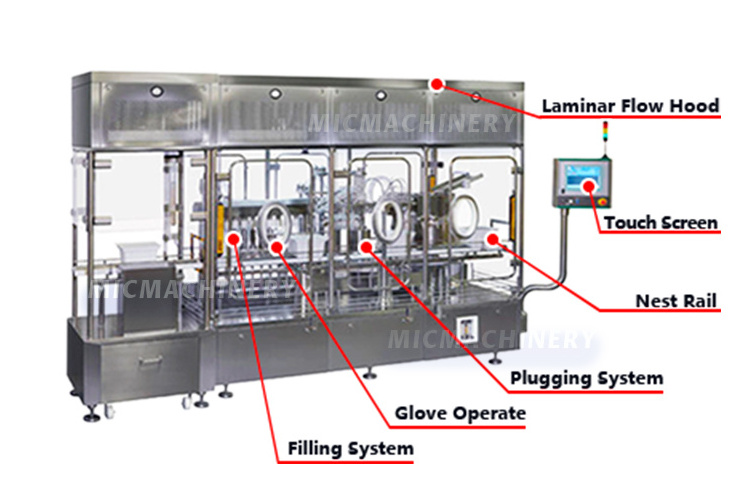

1. This machine is driven by a full servo motor system and adopts updated mechanical transmission.

2. The filling speed and filling volume is adjustable, the vacuum filling time is adjustable, the vacuum stoppering is also adjustable. It's very suitable for various viscosity material such as dental gel, sticky cream, oil and so on.

3. The HMI touch screen can save multi-standard production programs. After replacing the specifications, you can directly all the corresponding program screen.

4. This machine is easy to operate and running stable.

|

Technical Parameter

|

|

|

|

|

||||

|

Servo motion controller

|

Beckhoff (Germany)

|

AC contactor

|

Schneider (France)

|

|

||||

|

Servo motor

|

Kossi (Italy)

|

Breaker

|

Schneider (France)

|

|

||||

|

Servo driver

|

Kossi (Italy)

|

Relay

|

Panasonic (Japan)

|

|

||||

|

Touch screen (HMI)

|

Pro-face (France)

|

Photoelectric sensor

|

Leuze (Germany)

|

|

||||

|

Filling system: Peristaltic pump for

liquid

product. Ceramic rotary valve piston pump for viscosity product.

|

|

|

|

|

||||

Automatic Vacuum Filling System and Stoppering Station

This machine adopts peristaltic pump to fill the liquid into the syringes, we can also add the N2 injection function if you need. It will make 3/4/5 filling nozzles according to your syringe's volume. At the same time, the rubber stoppering is synchronized, when filling finished then adding the rubbers immediately.If your products is high viscosity gel, then we will use ceramic piston pump and rotary valve to fill, in order to prevent the bubbles caused, the filling process is vacuum.

Automatic Peristaltic Pump Filling System

This machine adopts high precision peristaltic pump servo filling system, the parameter is adjustable on the HMI.

Automatic Sorting and Feeding Rubbers

The high precision vibrating plate will vibrate and feed the rubbers into the stoppering station through the multi-row guide rail.We can make the different vibrating plate according to your different size rubbers.

Finished Product Output

When the nest is finished filling and stoppering, the chain conveyor will deliver it to the output hole automaticlly.

Hot Searches