- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Red yellow blue white orange light blue or customized

-

Logo:

-

Customized Logo Accepted

-

Helmet material:

-

FRP/PP/ABS

-

Pad material:

-

HDPE

-

Weight (kg):

-

0.39-0.43

-

MOQ:

-

36PCS

-

Product packaging size (cm):

-

30*68*78

-

Gross weight (kg):

-

16

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MING DUN

-

Model Number:

-

M-5

-

Color:

-

Red yellow blue white orange light blue or customized

-

Logo:

-

Customized Logo Accepted

-

Helmet material:

-

FRP/PP/ABS

-

Pad material:

-

HDPE

-

Weight (kg):

-

0.39-0.43

-

MOQ:

-

36PCS

-

Product packaging size (cm):

-

30*68*78

-

Gross weight (kg):

-

16

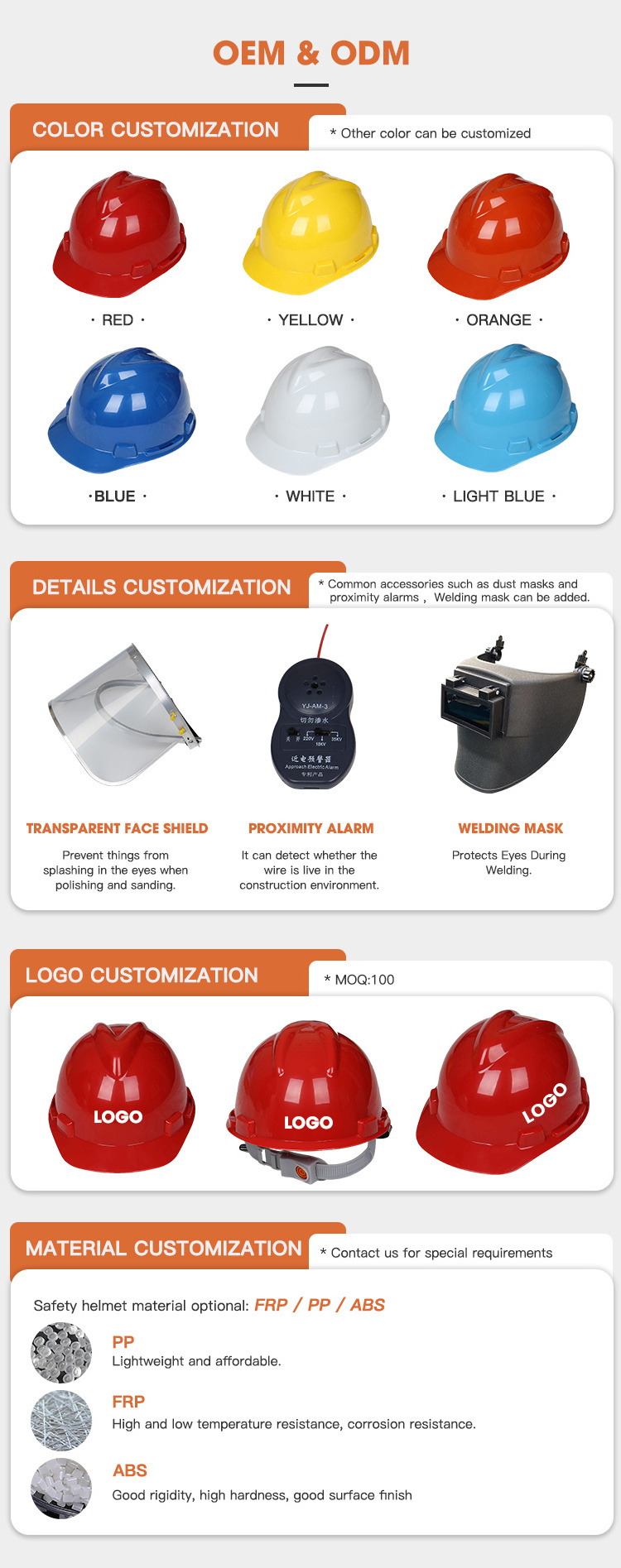

| MODEL | M-5 | ||

| helmet material | ABS | FRP | PP |

| pad material | HDPE | ||

| Weight (kg) | 0.41 | 0.43 | 0.39 |

| Color | Red yellow blue white orange light blue or customized | ||

| MOQ |

36PCS 36 products in a box |

||

| Product packaging size (cm) | 30*68*78 | ||

| Gross weight (kg) | 16 | ||

| Packing | 36pcs/box | ||

| Applicable industry | Applicable to electric power, chemical industry, petroleum, construction, forestry, port, metallurgy and other industries. | ||

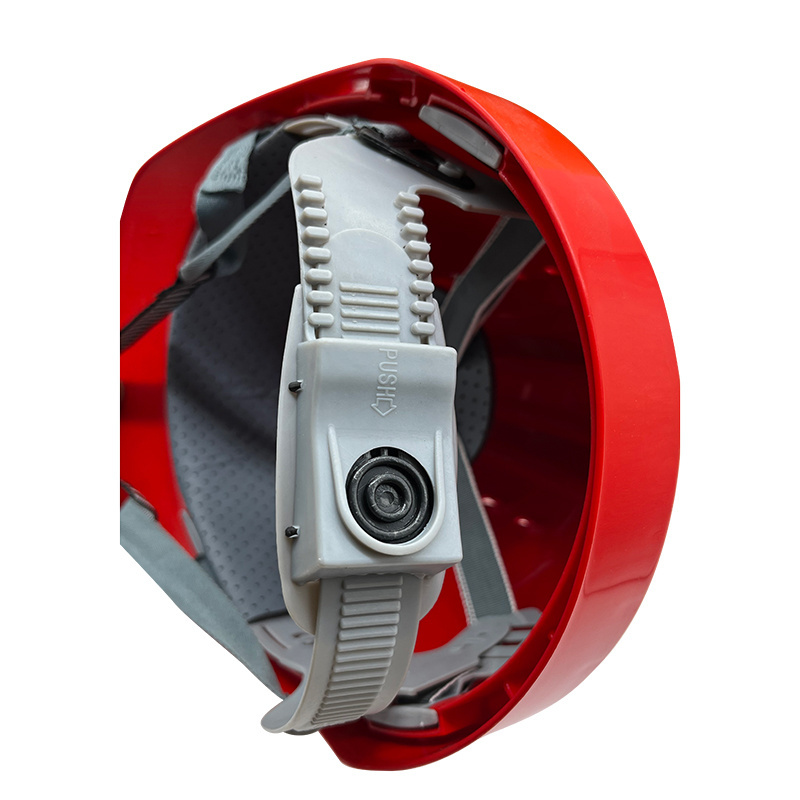

The cap shell is elliptical or hemispherical, with a smooth surface. When an object falls on the cap shell, the object cannot stay and slide off immediately; and the force of the cap shell is transmitted to the surrounding by the impact point, and the force reduced by the cap lining buffer can reach More than 2/3, the rest of the force is transmitted to the human skull through the entire area of the cap lining, which turns the force point into the force surface, thereby avoiding the stress concentration of the impact force at a certain point on the cap shell, reducing the impact force per unit area.

Pay attention to the principle

1. Before wearing, check whether the accessories of the helmet are damaged, whether the assembly is firm, whether the adjustment part of the cap lining is locked, whether the socket is firm, whether the rope is fastened, etc. If the distance between the cap lining and the cap shell is not 25 Between ~50mm, use the top rope to adjust to the specified range. Make sure all parts are in good condition before use.

2. According to the size of the user's head, adjust the length of the cap hoop to an appropriate position (appropriate tightness). The helmets worn by high-altitude workers must have a chin strap and a back neck cuff and be fastened to prevent the hat from slipping and taking off.

3. After the helmet is subjected to a large impact during use, no matter whether the cap shell is found to have obvious cracks or deformation, it should be stopped and the damaged helmet should be replaced. Generally, the use period of helmets does not exceed three years.

4. Helmets should not be stored in places with acid and alkali, high temperature (above 50°C), direct sunlight, humidity, etc., to avoid heavy objects or sharp objects.

5. The cap shell and cap lining can be washed with cold water and warm water (below 50℃). Do not bake on a radiator to prevent deformation of the cap shell.