- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JH21

-

Weight (T):

-

8

-

Product name:

-

puching press hole machine

-

Keyword:

-

Pneumatic Metal Punching Machine

-

Function:

-

Metal Processing

-

Application:

-

Auto Parts

-

Type:

-

Four Columns

-

Local Service Location:

-

United Kingdom

-

Usage:

-

Metal Press

-

Color:

-

Costomized

-

Punching machine:

-

Pneumatic Punching Press Machine

Quick Details

-

Slide Stroke (mm):

-

140

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

cowardson

-

Model Number:

-

JH21

-

Weight (T):

-

8

-

Product name:

-

puching press hole machine

-

Keyword:

-

Pneumatic Metal Punching Machine

-

Function:

-

Metal Processing

-

Application:

-

Auto Parts

-

Type:

-

Four Columns

-

Local Service Location:

-

United Kingdom

-

Usage:

-

Metal Press

-

Color:

-

Costomized

-

Punching machine:

-

Pneumatic Punching Press Machine

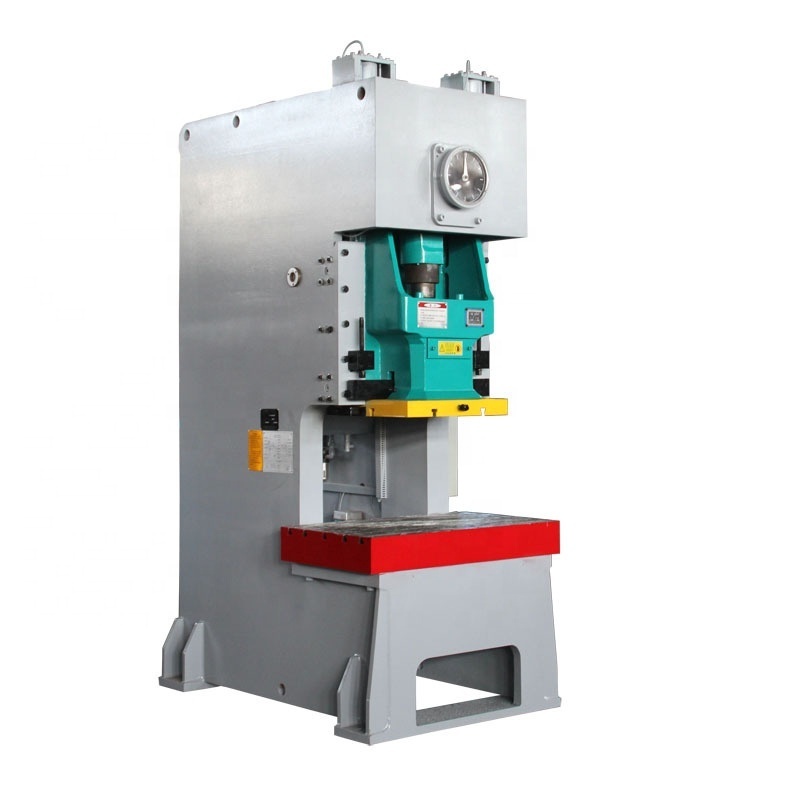

JH21-80 ton pneumatic punching machine

Product Description

Pneumatic punching machine, also known as high-performance pneumatic punching press, pneumatic friction clutch punching machine, is an open C-shaped body, with simple structure and low production cost. It adopts pneumatic technology to realize that one air compressor can supply multiple pneumatic punching holes at the same time. Machine work, more energy-saving than electric punch. Reduce power consumption. The operation is simple and the safety is high. The foot switch is used to control the solenoid valve, the structure is simple, the failure rate is low, and the production efficiency is improved. The pneumatic punching machine uses the high-pressure gas generated by the compressor to deliver the compressed gas to the solenoid valve through the pipeline, and controls the action of the solenoid valve through the foot switch to control the work and return of the cylinder, so as to achieve the purpose of punching.

Specification

|

Type [Model]

|

63 T

|

80 T

|

125 T

|

160 T

|

200 T

|

|

nomal force

|

630kN

|

800kN

|

1250kN

|

1600kN

|

2000kN

|

|

Ability occurrence point(mm)

|

4

|

5

|

5

|

6

|

6

|

|

slide stroke(mm)

|

120

|

140

|

160

|

180

|

200

|

|

max die set height(mm)

|

300

|

320

|

370

|

400

|

450

|

|

Number of stroke of slider(mm)

|

70

|

60

|

50

|

45

|

40

|

|

Mold height adjustment(mm)

|

80

|

80

|

100

|

110

|

110

|

|

throat depth(mm)

|

300

|

300

|

370

|

390

|

430

|

|

Slider surface size(mm)

|

400×480

|

420×560

|

520×620

|

580×700

|

650×880

|

|

bed dimension(mm)

|

900 ×580

|

1000 ×580

|

1120 ×720

|

1200 ×760

|

1400 ×840

|

|

The main motor(mm)

|

5.5×6

|

7.5×4

|

11×4

|

15×6

|

18.5×6

|

Details display

1. Safety, pneumatic punches have higher safety performance than traditional punches;

2. Precision, the pneumatic punch is more precise than the traditional punch; the upper and lower dies are more convenient than the traditional punch;

3. The speed is faster than that of the pneumatic punch; the pneumatic punch has a cylinder, which requires air, but the traditional one does not;

4. The price of pneumatic punch is higher than that of traditional punch.

production products

Machinery industry: stamping parts, stamping processing, metal stamping parts, metal stamping parts, automobile stamping parts, drawing parts, metal drawing parts, stamping sheet metal parts.

Packing & Delivery

All machines are packed in wood to ensure safety during transportation

Hot Searches