- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shuguang brand

-

Dimension(L*W*H):

-

4.5*3.5*5m

-

Weight:

-

4500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine name:

-

Grinding Raymond Mill Price

-

Usage:

-

for grinding mining stone etc.

-

Inlet size:

-

less than 25mm

-

Outlet size:

-

60-325 mesh

-

Raw material:

-

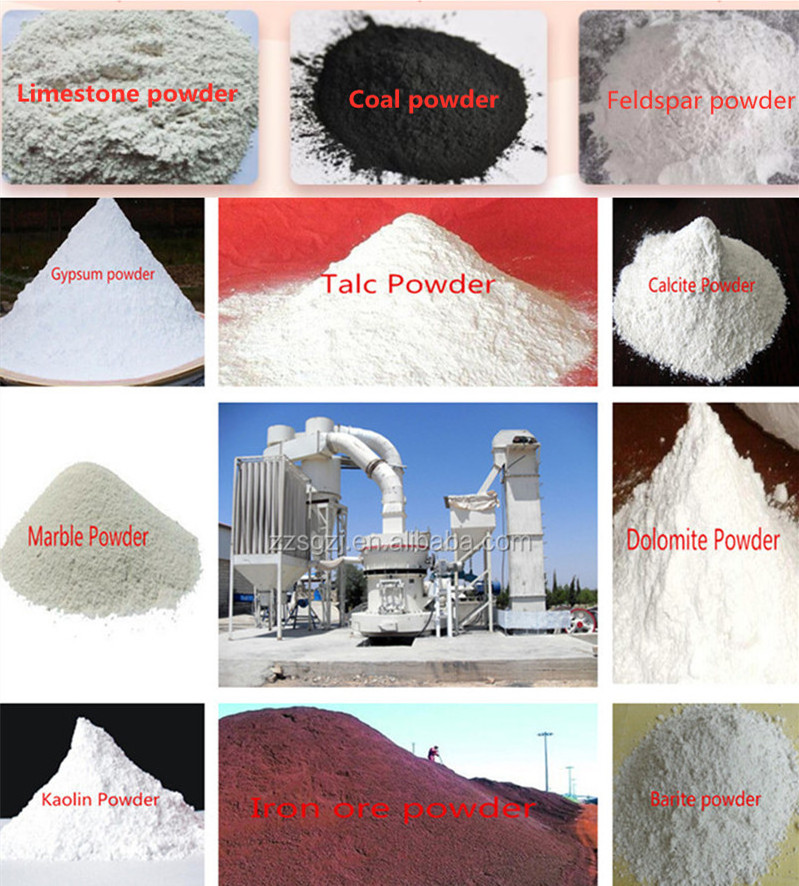

marble,calcite,gypsum,barite etc

-

Speed:

-

160 r/min

-

Wearing parts:

-

grinding roller and ring

-

diameter of roller:

-

300 mm

-

hegiht of roller:

-

150 mm

Quick Details

-

Marketing Type:

-

New Product 2023

-

Capacity(t/h):

-

1-4 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuguang brand

-

Dimension(L*W*H):

-

4.5*3.5*5m

-

Weight:

-

4500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine name:

-

Grinding Raymond Mill Price

-

Usage:

-

for grinding mining stone etc.

-

Inlet size:

-

less than 25mm

-

Outlet size:

-

60-325 mesh

-

Raw material:

-

marble,calcite,gypsum,barite etc

-

Speed:

-

160 r/min

-

Wearing parts:

-

grinding roller and ring

-

diameter of roller:

-

300 mm

-

hegiht of roller:

-

150 mm

Raymond mill is widely used for non-flammable and non-explosive materials with Moh hardness below grade 9.3 and water content less than 6%. such as: Quartz, recrystallization, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite, glass, titanium ore, copper ore, chrome ore, manganese ore, refractory materials, insulation materials, coal tar, coal powder, carbon black, clay, titanium dioxide, iron oxide. The final size ranges from 60 mesh to 325 mesh (0.044mm to 0.125mm), and some parts can be 1000 mesh (0.013mm).

limestone,dolomite,fluorite and lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass and thermalinsulation material in mine, metallurgy, chemistry and building industry.

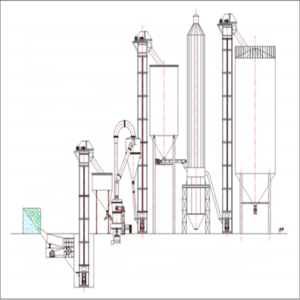

Raymond Mill's working principle is that the grinding roller is rolled tightly on the grinding ring under the action of centrifugal force. The shovel scoops the material to the middle of the grinding roller and the grinding ring. The material is broken into powder under the action of the grinding pressure, and then Under the action of the fan, the powdered material is blown through the analyzer, and the fineness-required material passes through the analyzer. The regrind chamber can no longer meet the required requirements and continue to be ground. The material of the analyzer enters the cyclone separator and is collected and collected. The exhaust uses industrial filter cloth to separate exhaust air into powder.

|

Product Name

|

4r3216 Raymond Grinding Mill

|

|

Material

|

Carbon steel

|

|

Feeding size

|

less than 25mm

|

|

Finished product size

|

60-325 mesh(0.125-0.044mm)

|

|

Capacity

|

2-8t/h

|

|

Diameter of ring

|

970mm

|

|

Diameter of roller

|

320mm

|

|

Height of roller

|

160mm

|

Raymond Mill's complete structure is composed of main engine, analyzer (pulverizer), pipeline device, blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electronically controlled motor and other components. Raymond Mill's main machine consists of a frame, air inlet volute, blade,grinding roller, agrinding ring, cover and motor.

Main Features

1) Product size is in the scope of 0.163mm 30 mesh to 0.033mm 425mesh

2) Mons, hardness scale is less than grade three

3) The efficient of dust removal can reach national standard

4) Detailed analysis machine, easy to adjust impurity separator

5) The main axle is capable of sealing which uses stacked multistage seal

Why choose Shuguang Factory?

A. 20 years' experience in Heavy machinery industry.

B. Customers from more than 120 countries.

C. Professional team offers technical support to customers.

D. 24hours online services from our professional foreign trade department.

E. All our machines passed the CE certificate.

F. Our technicians go to different countries to help customers.

A: Yes. Many domestic and international customers visit our factory every year.

Q: How long is the warranty of your equipment? Do you supply spare parts?

A: Our warranty period is one year generally. We can supply spare parts.

Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: How long is your delivery time?

A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.