- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Load support/Slope stabilization/Retaining wall, Road Basement

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LUXIN

-

Model Number:

-

LUXIN001

-

Material:

-

HDPE

-

Product name:

-

Geocell Gravel Grid

-

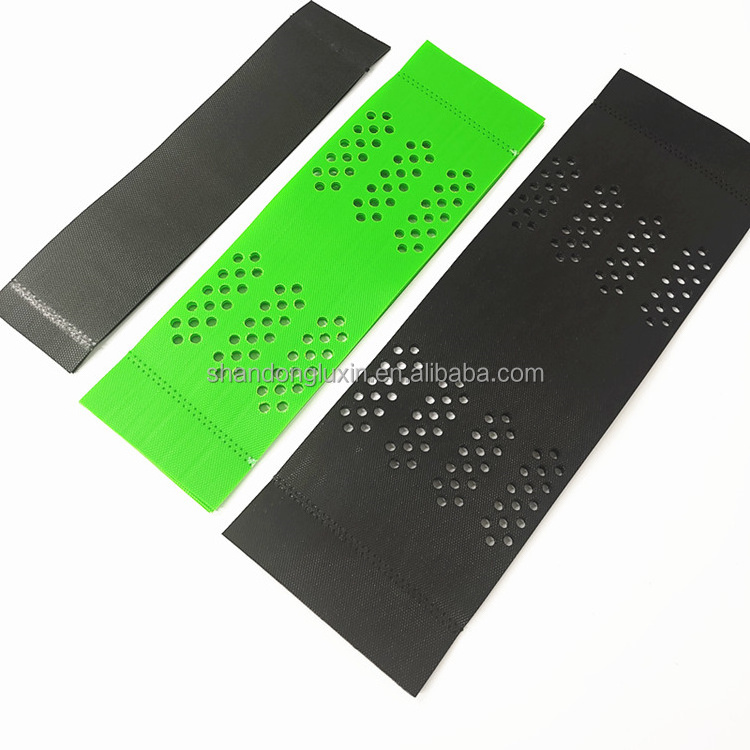

Color:

-

Black

-

Keyword:

-

Soil Stabilization Geocell Grid

-

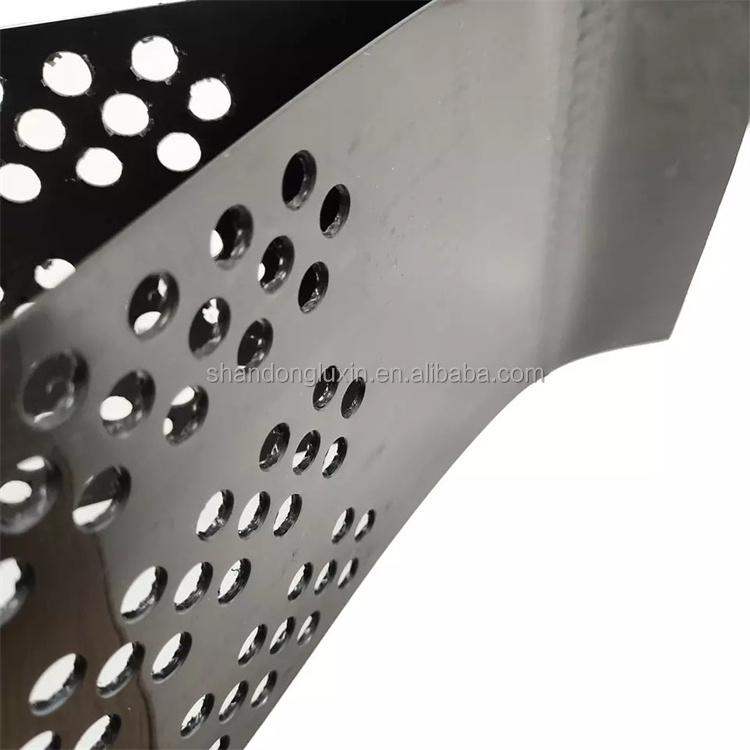

Thickness(textured):

-

1.0-1.7mm

-

Welding distance:

-

330mm-1000mm

-

Surface:

-

Textured Smooth

-

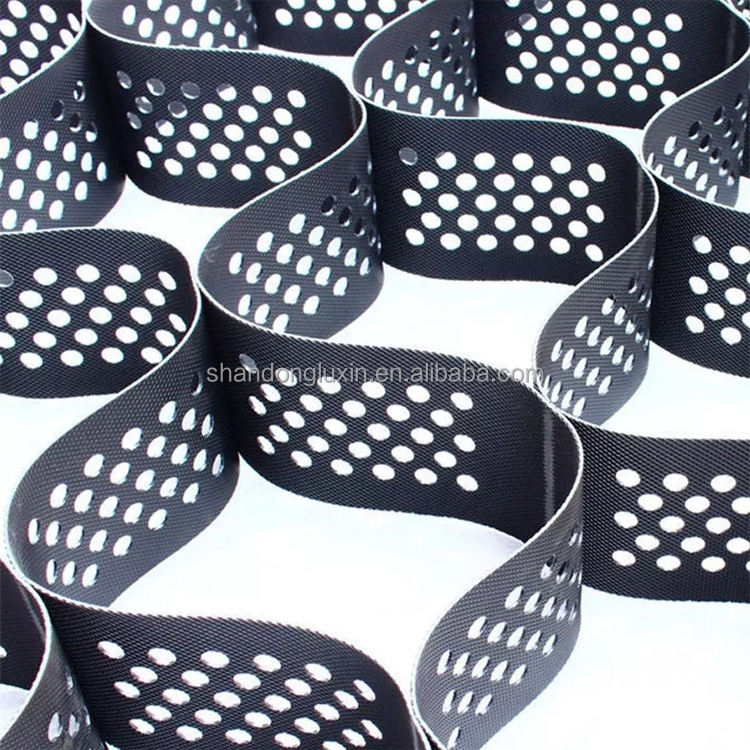

Package:

-

Plastic Packing Belts

-

Description:

-

Textured Perforated Geocell Product

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Load support/Slope stabilization/Retaining wall, Road Basement

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LUXIN

-

Model Number:

-

LUXIN001

-

Material:

-

HDPE

-

Product name:

-

Geocell Gravel Grid

-

Color:

-

Black

-

Keyword:

-

Soil Stabilization Geocell Grid

-

Thickness(textured):

-

1.0-1.7mm

-

Welding distance:

-

330mm-1000mm

-

Surface:

-

Textured Smooth

-

Package:

-

Plastic Packing Belts

-

Description:

-

Textured Perforated Geocell Product

Product Description

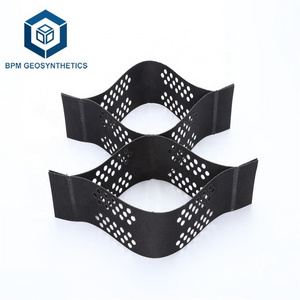

GEOCELL is produced from High Density Polyethylene (HDPE) and has a three-dimensional cellular confinement system that confines and strengthens infill material including native fill, topsoil, granular or concrete, within the cells of its honeycomb-like structure.

Within the interconnected cells, GEOCELL serves many benefits to the material it confines, such as boosting weight-bearing capabilities, preventing lateral movement, and providing durable stabilization. There are four main applications that geocell provides solutions: soil stabilization, erosion control, channel protection, and retaining walls. It is being widely used in construction, such as highway, railway, bridge, dyke, etc.

|

Product Name

|

Geocell

|

|

Cell Depth

|

50, 75, 100, 125, 150, 200mm

|

|

Weld Spacing

|

330, 356, 400, 445, 660, 712mm

|

|

Thickness(Textured)

|

1.5, 1.52, 1.6mm

|

|

Thickness(Smooth)

|

1.1, 1.2mm

|

|

Colour

|

Black, Sandy, Green

|

|

Standard

|

ASTM, ISO

|

Product Specification

|

Cell

|

Test Method

|

Units

|

Values

|

||

|

Material

|

-

|

-

|

Virgin HDPE

|

||

|

ESCR

|

ASTM D1603

|

Hours

|

400

|

||

|

Density

|

ASTM D1505

|

g/cm3

|

0.945-0.960

|

||

|

Thickness(smooth)

|

ASTM D5199

|

mm

|

1.20 (-5% +10%)

|

||

|

Thickness(Textured)

|

ASTM D5199

|

mm

|

1.50 (-5% +10%)

|

||

|

Carbon Black

|

ASTM D1603

|

%

|

≥ 1.5

|

||

|

Seam Peel Strength

|

USACE GL-86-19

|

N

|

≥ 15KN/m

|

||

|

Tensile Strength at Break

|

ASTM D638

|

KN/m2

|

≥ 32000 (TD) / ≥ 30000 kN (MD)

|

||

|

Elongation at Break

|

ASTM D6693

|

|

≥ 900 (TD) / ≥ 480 (MD)

|

||

|

Oxidative Induction Time

|

ASTM D3895

|

min

|

≥150

|

||

|

Long-term

Seam Peel Strength |

Long term seam peel strength test shall be performed on all resin or pre-manufactured sheet or strips. A 100mm wide seam sample

shall support a 72.5kg load for a period of 168 hours minimum in a temperature controlled environment undergoing a temperature change on a 1-hour cycle from 23ºC to 54ºC |

|

|

||

Application

1. Used for all kinds of road building, driveways, soil stabilization and embankment stabilization

2. Used to stabilize river embankments.

3. Used to prevent landslides.

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed, construction speed, good

performance and greatly reduce the project cost.

2. Used to stabilize river embankments.

3. Used to prevent landslides.

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed, construction speed, good

performance and greatly reduce the project cost.

Workshop

Customer Photos

Hot Searches