- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Packaging Type:

-

Tubes

-

Driven Type:

-

Electric & pneumatic

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOPCN

-

Dimension(L*W*H):

-

110*95*170cm

-

Weight:

-

280 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

semi automatic tube filling sealing machine

-

Flling range:

-

2-250ml(can be adjusted)

-

Filling speed:

-

10-20tubes/min

-

Filling accuracy:

-

±0.5%

-

Filling machine material:

-

304 & 316 stainless steel

-

Certification:

-

CE ISO

-

Marketing Type:

-

Hot Product

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Other

-

Filling Accuracy:

-

±0.5%

-

Packaging Type:

-

Tubes

-

Driven Type:

-

Electric & pneumatic

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOPCN

-

Dimension(L*W*H):

-

110*95*170cm

-

Weight:

-

280 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

semi automatic tube filling sealing machine

-

Flling range:

-

2-250ml(can be adjusted)

-

Filling speed:

-

10-20tubes/min

-

Filling accuracy:

-

±0.5%

-

Filling machine material:

-

304 & 316 stainless steel

-

Certification:

-

CE ISO

-

Marketing Type:

-

Hot Product

1. semi automatic tube filling sealing machine to replace the traditional welding or bonding process, low cost, clean pollution-free and does not damage the plastic tube.

2. cream tube sealing machinery is equipped with Airtac cylinders and Airtac magnetic valves, stable performance.

3.

pe tube sealing machine

Intelligent automatic frequency tracking system, which can recognize the vibration frequency of

the ultrasonic system automatically, so as to effectively protect the mold. Large output, small noise, stable performance,

long life.

4. heating sealing tube machine High welding strength, Good sealing performance, the strength of welding area is same as other area of the plastic.

5. Precision IC control circuit, automatic overload protection system.

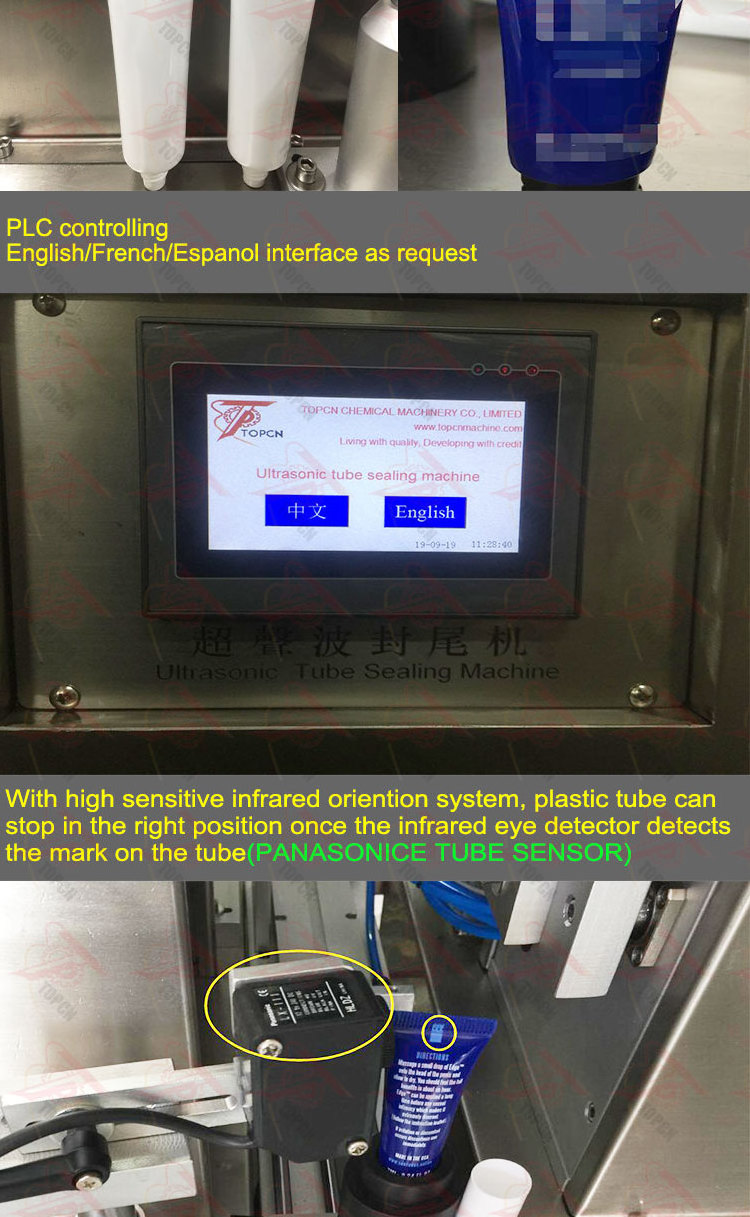

6. hot air tube sealing machine adopting PLC controller, easy to operate,autoprotecting system can avoid the damage caused by improper operation.

7. Four points balance adjustment, easy to adjust the welding head.

8. Aluminum/titanium radial pole, sonic, strong stability.

9. The cone to press the tube on the orientation position, can assure tube is round.

10, Hot sell pharma mixing ultrasonic heating PE cream semi automatic tube filling sealing machine can adjust filling volume easily.

11. pharma tube filling machine sealing and cutting are on different positions, can avoid burrs.

12. Install cold water circulation in back mold, which can assure sealing quality under high output status.

13. Stepper motor is used for orientation, the speed can be adjusted to improve the accuracy.

14. Stable welding process, easy operation, easy maintenance.

15. Auto Orientate, Sealing, Print code, Cutting.

|

Ultrasonic Power

|

|

2000 W

|

|

|

|

Frequency

|

|

20 KHz

|

|

|

|

Power Supply

|

|

AC 110/220V, 50/60Hz

|

|

|

|

Delay Time

|

|

0.01-2.99 S

|

|

|

|

WeldTime

|

|

0.01-2.99 S

|

|

|

|

Hold Time

|

|

0.01-2.99 S

|

|

|

|

Driven Mode

|

|

Pneumatic

|

|

|

|

Stroke

|

|

75 MM

|

|

|

|

Working Pressure

|

|

0.5-0.7 MPa

|

|

|

|

Tube Diameter Range

|

|

10-50 MM

|

|

|

|

Tube Height Range

|

|

50-200 MM

|

|

|

|

Filling Range

|

|

A: 5-60 ml B: 10-120 ml C: 25-250 ml D: 50-500 ml

|

|

|

|

Heating power

|

|

800W*2

|

|

|

|

Mixing motor power

|

|

200W

|

|

|

|

Hopper capacity

|

|

30L

|

|

|

|

Capacity

|

|

around 10 tubes/min

|

|

|

|

Packing Dimension

|

|

L*W*H 1110*840*1510MM=1.4CBM

|

|

|

|

Gross Weight

|

|

260KGS

|

|

|

|

HS code

|

|

8422303090

|

|

|

Q1: Are you a machine manufacturer or trading company?

A1:

We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2:

Every machine is tested by our factory and other client before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3:

We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4:

It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, etc,.

Q5: What should I do to choose the best machine for us?

A5:

1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q6: Do you have manual or operation video for us to know more about the machine?

A6:

Yes, we will send you the manual and operation video after you ask for us.

Q7: If there's some spare parts that broke,how to solve the problem?

A7:

Yes, we will send you the manual and operation video after you ask for us.

Q8: If there's some spare parts that broke,how to solve the problem?

A8:

First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides,we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Q9: Do you have manual or operation video for us to know more about the machine?

A9:

Yes, we will send you the manual and operation video after you ask for us.

Q10: If there's some spare parts that broke,how to solve the problem?

A10:

Yes, we will send you the manual and operation video after you ask for us.

Q11: If there's some spare parts that broke,how to solve the problem?

A11:

First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side