fertilizer, ferrous metal, nonferrous metal and glass ceramics.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhengzhou Haoding Machinery

-

Weight:

-

40000 KG, 1.5-65t

-

Dimension(L*W*H):

-

According to the model

-

Feeding size:

-

20-25mm

-

Capacity:

-

0.65-90t/h

-

Power:

-

18.5-800KW

-

Product name:

-

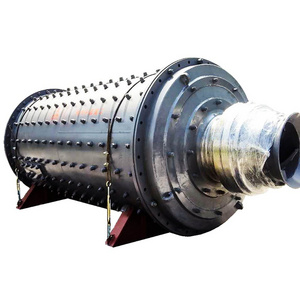

Ball mill

-

Usage:

-

Grinding Mining Stone

-

Factory Visit:

-

Welcomed Warmly

Quick Details

-

Marketing Type:

-

Hot Product

-

Capacity(t/h):

-

0.65-90t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhengzhou Haoding Machinery

-

Weight:

-

40000 KG, 1.5-65t

-

Dimension(L*W*H):

-

According to the model

-

Feeding size:

-

20-25mm

-

Capacity:

-

0.65-90t/h

-

Power:

-

18.5-800KW

-

Product name:

-

Ball mill

-

Usage:

-

Grinding Mining Stone

-

Factory Visit:

-

Welcomed Warmly

Products Description

fertilizer, ferrous metal, nonferrous metal and glass ceramics.

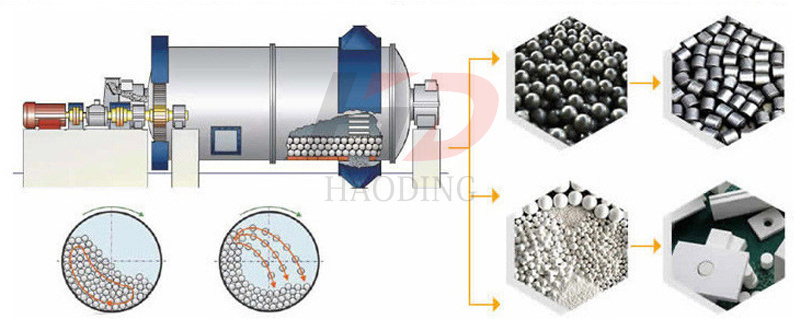

Working principle:

Ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber

through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the

chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials into fine powder over a period of several hours. The ground materials are discharged through the discharging board thus the grinding process is finished.

through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the

chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials into fine powder over a period of several hours. The ground materials are discharged through the discharging board thus the grinding process is finished.

|

Model

|

Feeding size(mm)

|

Discharging size(mm)

|

Capacity(t/h)

|

Power(kw)

|

Weight(t)

|

|

900*1800

|

≤20

|

0.075-0.089

|

0.65-2

|

18.5

|

1.5

|

|

900*3000

|

≤20

|

0.075-0.089

|

1.1-3.5

|

22

|

2.7

|

|

1200*2400

|

≤25

|

0.075-0.6

|

1.6-5.8

|

37

|

4.6

|

|

1200*4500

|

≤25

|

0.074-0.4

|

1.6-5.8

|

55

|

5.5

|

|

1500*3000

|

≤25

|

0.074-0.4

|

2-5

|

75

|

9

|

|

1500*5700

|

≤25

|

0.074-0.4

|

3.5-6

|

130

|

17

|

|

1830*4500

|

≤25

|

0.074-0.4

|

4.5-12

|

155

|

15

|

|

1830*6400

|

≤25

|

0.074-0.4

|

6.5-15

|

210

|

21

|

|

1830*7000

|

≤25

|

0.074-0.4

|

7.5-17

|

245

|

23

|

|

2100*4500

|

≤25

|

0.074-0.4

|

8-43

|

245

|

24

|

|

2100*7000

|

≤25

|

0.074-0.4

|

8-48

|

280

|

26

|

|

2200*4500

|

≤25

|

0.074-0.4

|

9-45

|

280

|

27

|

|

2200*6500

|

≤25

|

0.074-0.4

|

14-26

|

380

|

35

|

|

2200*7000

|

≤25

|

0.074-0.4

|

15-28

|

380

|

35

|

|

2400*3000

|

≤25

|

0.074-0.4

|

30-50

|

245

|

23

|

|

2400*4500

|

≤25

|

0.074-0.4

|

40-60

|

320

|

30

|

|

2700*3600

|

≤25

|

0.074-0.4

|

45-80

|

430

|

40

|

|

2700*4500

|

≤25

|

0.074-0.4

|

50-90

|

430

|

48

|

|

2700*13000

|

≤25

|

0.074-0.4

|

50-90

|

630

|

60

|

|

3200*4500

|

≤25

|

0.074-0.4

|

-

|

800

|

65

|

Advantages

1.High efficiency and low invest with high return.

2.Even product size that means the shape of the final products is circular.

3.Easy operation and easy maintenance.

4.Good stability and low energy consumption.

5.Adjustable device.

6.No pollution and low noise.

2.Even product size that means the shape of the final products is circular.

3.Easy operation and easy maintenance.

4.Good stability and low energy consumption.

5.Adjustable device.

6.No pollution and low noise.

Customer Photos

Hot Searches