- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4500x2300x2000

-

Year:

-

as order

-

Power (kW):

-

45

-

Weight (KG):

-

7560 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control:

-

Automatic control

-

Min thickness of products:

-

0.1-0.2mm

-

Products width:

-

100-2150mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SFC

-

Voltage:

-

As your requirement

-

Dimension(L*W*H):

-

4500x2300x2000

-

Year:

-

as order

-

Power (kW):

-

45

-

Weight (KG):

-

7560 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control:

-

Automatic control

-

Min thickness of products:

-

0.1-0.2mm

-

Products width:

-

100-2150mm

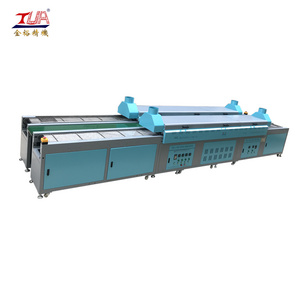

Fabric/Rubber/PVC Film/Conveyor Belt Calender Machinery

Rubberizing and fractioning of textile material, rubberizing of wirecord fabric, sheet, and counter plate(embossed) of rubber material, separation of fabric and film, as well as joint of multi-layer laminate film.

Calender Machinery General design:

It mainly contains roller, rack, backplane, adjustment, device, transmission system, roller temperature control device, security device, lubricating device, etc.

Calender Machinery Features:

1. This three rollers rubber calender is driven by AC motor with a wide range of speed adjustment, which allows a wide rang of speed adjustment. Working linear speeds can be steplessly changed within the fixed range. The rolls are equipped with bearings lubrication failure alarm device, as well as nip display and speed display.

2. The rollers are made of chilled cast iron with vanadium and titanium alloys. The roll face is hard and anti-wear. To heat up or cool down, the rolls are either circumferentially drilled or centrally bored so as to make temperature well proportioned on the roll surface.

3. The rollers are arranged in I, and L forms. The upper rolls have roll cambers that can eliminate bending impact on rolls during working process. Thus, it is possible to make products with same thickness along axial direction.

4. Roll spacing can be adjusted both by manual or electric mode.

5. The transmission system adopts a hard facing gear reducer, which has a compacted structure with higher transmission efficiency, lower noise and longer service life.

6. The machine is equipped with emergency device. When an emergent accident occurs, the calendar will be immediately stopped to open the roll space so as to protect the operator and equipment.

Application:

1. The Calender Machinery - Rubber Machinery is mostly used in oppression of rubber products and textile(like cotton, rayon, nylon etc). The precision calender besides has the ordinary calender main spare part and the equipment, increased the guarantee rolling precision installment.

2. We have three-roll, four-roll and two-roll calender, should any of items be of interest to you, please contact me for further details.

3. Calender Machinery- Rubber Machinery is according to certain form arrangement, under certain temperature, extends the rubber or the plastic suppression certain thickness and the superficial shape film.

|

Model |

XY-630 |

XY-900 |

XY-1120 |

XY-1400 |

XY-1500 |

XY-1730 |

XY-2130 |

XY-2430 |

|

Roll DiameterxLength |

230x630 |

360x900 |

360x1120 |

400x1400 |

450x1500 |

610x1730 |

710x2130 |

810x2430 |

|

Friction Ratio |

1:1:1 1:1.42:1 |

1:1:1 0.733:1:1 0.733:1:0.733 |

1:1:1 |

1:1:1 1:1.383:1.383 1:1.383:1 |

1:1:1 1:1.5:1 |

1:1:1 1:1.4:1 |

1:1:1 |

1:1:1 1:1.5:1 |

|

Middle Roller Linear Speed(RPM) |

0.8-8 |

3-21.06 |

1.5-15 |

3-26.39 |

2.62-26.2 |

5.4-54 |

8-50 |

2-20 |

|

Nip Adjustment Range(mm) |

0-7 |

0-10 |

0-10 |

0-10 |

0-6 |

0-20 |

0-20 |

0.5-25 |

|

Min. Thickness of Products(mm) |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.15 |

0.15 |

0.15 |

|

Products Width(mm) |

100-500 |

700 |

920 |

1200 |

1400 |

1530 |

1900 |

2150 |

|

Main Motor Power(KW) |

7.5 |

45 |

45 |

55 |

75 |

132 |

185 |

220 |

Our engineers can design target machines for customers and send them the drawing to confirm. We are always on the side of saving your cost.

In the process of production, we will take photos and send to customers for their track the progress.

Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

We supply overseas engineer service and help to train your workers to operate the machine.

1. Delivery time of the rubber machines?

This is specially designed machine according to your specific requirement.

From engineer designing to production completion, it needs about 25 to 35 days.

2. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production.

Every machine will be fully assembled and carefully tested before shipment.

3. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

4. Are you able to give installation and commissioning overseas? How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation.

Small machine usually takes within 2~3 days.

Big plant usually takes about 30 days.

5. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order.

The core of our company culture is innovation, quality, integrity and efficiency. Also we have had much good cooperation with world famous rubber production manufacturers. If you come to our factory, we can show you're the user around us.

6. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao Liuting airport.

We will pick up you at the airport.

Welcome to our factory!