- Product Details

- {{item.text}}

Quick Details

-

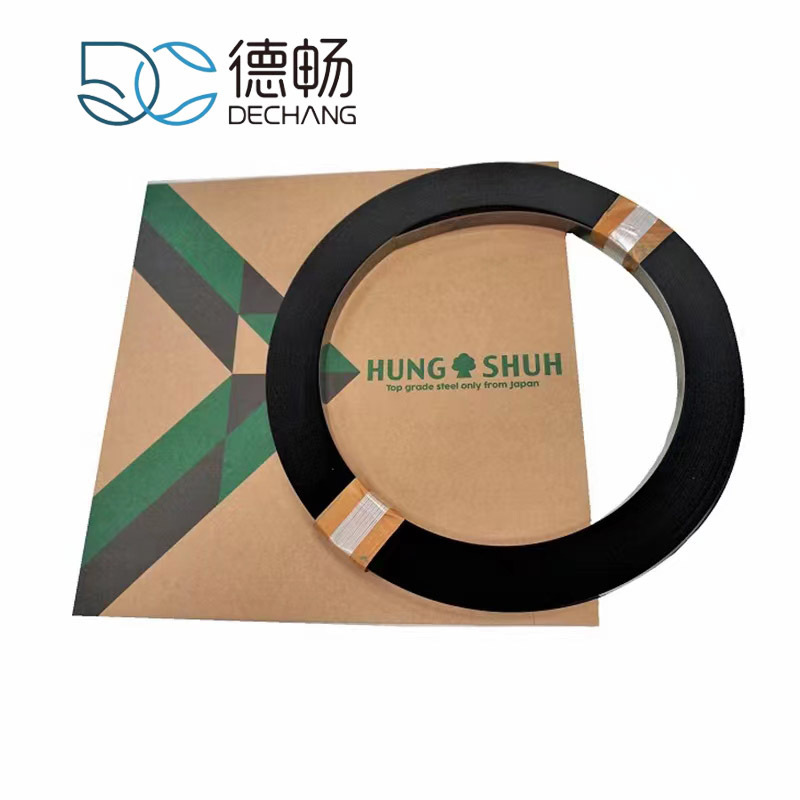

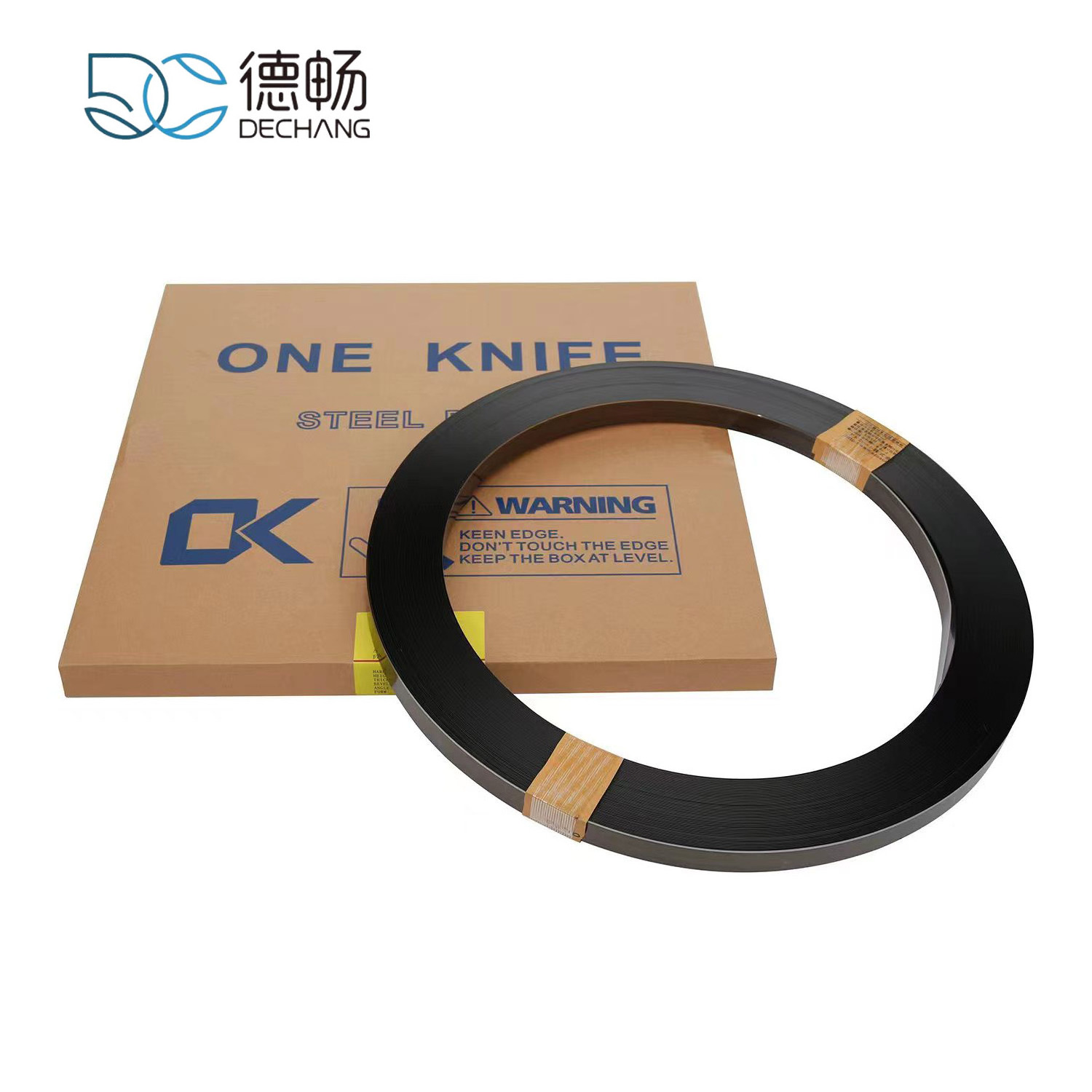

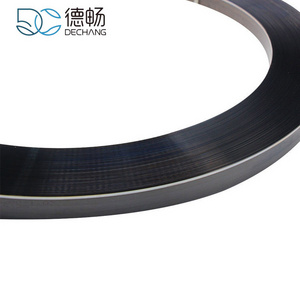

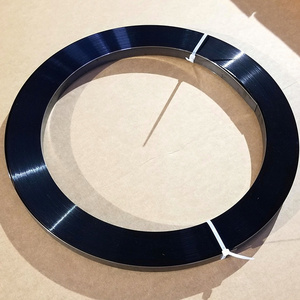

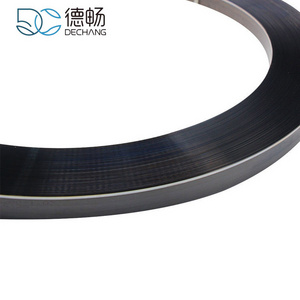

Product Name:

-

Cutting and Creasing Rule

-

Model No.:

-

DC-CT007

-

size:

-

23.60*0.45mm, 23.80*0.53mm,23.80*0.71mm

-

length:

-

23.60mm, 23.80mm

-

Material:

-

Steel

-

Usage:

-

Die Making For Printing Press

Quick Details

-

Model Number:

-

DC-CT007

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dechang, Dechang

-

Product Name:

-

Cutting and Creasing Rule

-

Model No.:

-

DC-CT007

-

size:

-

23.60*0.45mm, 23.80*0.53mm,23.80*0.71mm

-

length:

-

23.60mm, 23.80mm

-

Material:

-

Steel

-

Usage:

-

Die Making For Printing Press

|

Produce Name

|

Cutting and Creasing Rule

|

|

Material

|

Steel

|

|

Size

|

23.60*0.45mm, 23.80*0.53mm, 23.80*0.71mm

|

|

Length

|

23.60*0.45mm, 23.80mm

|

|

MOQ

|

10Rolls

|

|

Feature

|

Die Making For Printing Press

|

|

Delivery Time

|

About 3-7 Working Days After Payment

|

|

Payment

|

heipVISA, T/T, Weston Union, Trade Trade Assuranceand etc.

|

|

Shipping Method

|

By Sea,DHL,Fedex,TNT,UPS and ect.

|

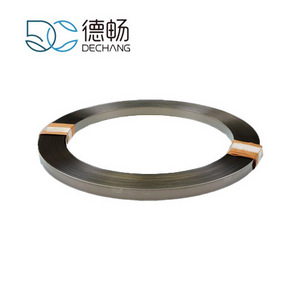

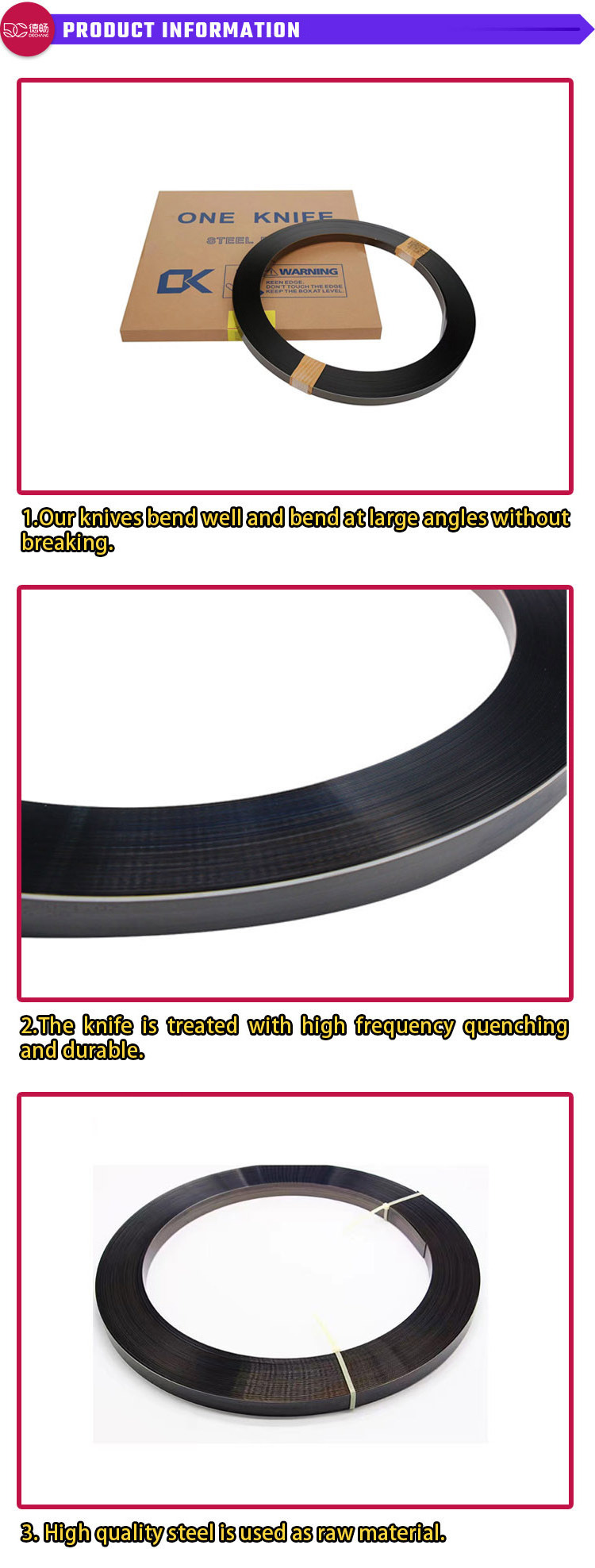

1.

Complete specifications, super stable.

Die-cutting knife specifications complete, knife edge for high-frequencyquenching, extend the number of die-cutting, to meet the needs of variousprocessing products die cutting.

2.

Selected quality materials.

The steel molecular structure is tight, the tool body is flexible, there is nomuch rebound after bending, and the molecular structure still maintains aclose connection.

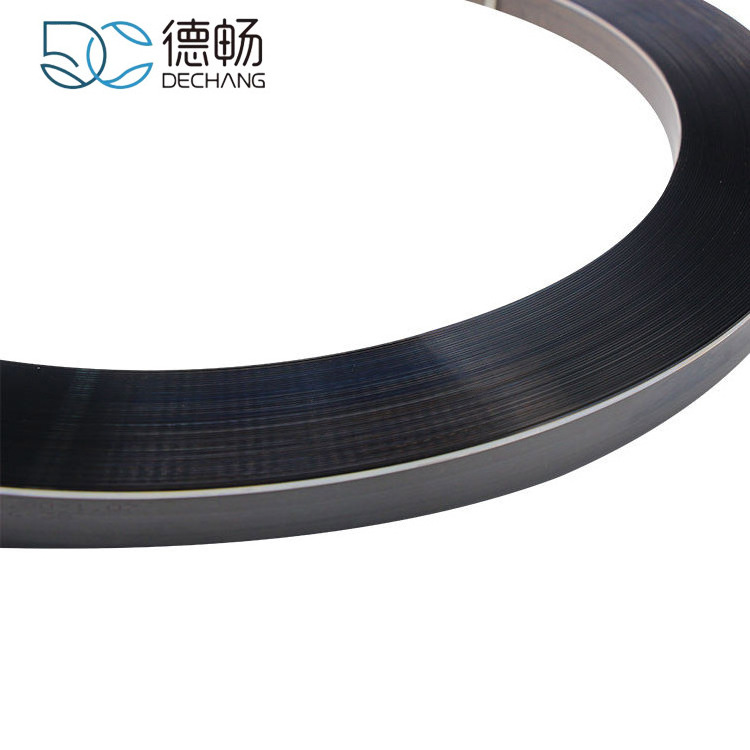

3.

Exquisite surface decarbonization treatment.

The more brittle carbon molecules will recede from the surface of the diecutter, so that the blade will not be brittle when bending, and it is more con-venient to bend and form.

4.

Excellent heat treatment.

The die cutter can be adjusted to different hardness according to differentrequirements of customers, and the tool body is soft for bending and theblade is hardened to make it durable.

5.

High precision.

The higher the precision of the die cutting tool, the shorter the pressurerequlation time of the die cutting machine, the lower the mechanical wearthe faster the production speed, the better the die cutting effect.

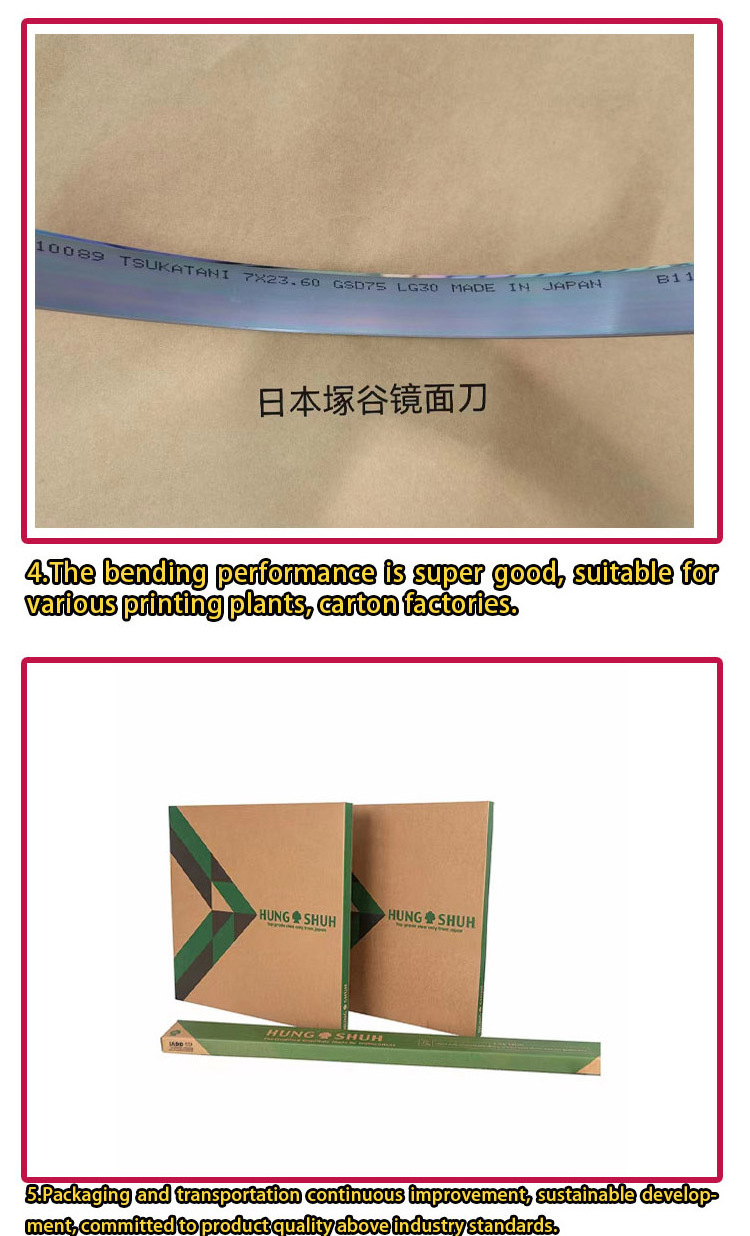

1.

JAPANESE DIE CUTTER HAS A LONG HISTORY.

Advanced knife technology, unique sharp edge, moderate hardness, goodbending performance, long service life.

2.ORDINARY DIE CUTTING KNIFE MAKING EXPERIENCEIS SHORT.

The quality of raw materials is general, the process technology is checked,the cutting edge is uneven, the bending performance is poor, and the ser-vice life is short. General products can not be cut through, frequent blade re-placement.

Hot Searches