- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FAYGO

-

Voltage:

-

customerized

-

Dimension(L*W*H):

-

3.3X1X2.3

-

Weight (KG):

-

3000 KG

-

Warranty:

-

1

-

After-sales Service Provided:

-

Overseas service center available

-

Automatic:

-

Yes

-

Name:

-

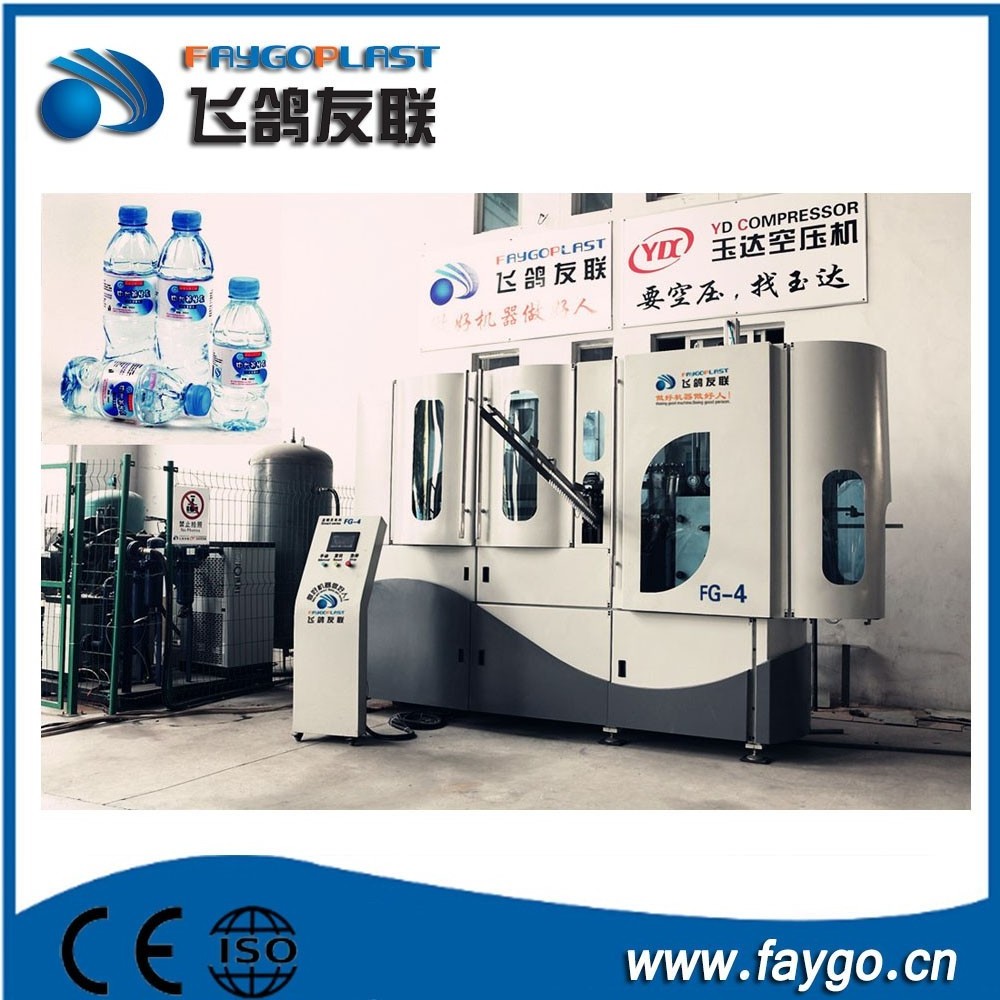

automatic pet water bottle making machine

-

Type:

-

FG-4 PET bottle making machine

-

Capacity:

-

6500-7200

-

PLC:

-

MITISUBISHI Japan

-

Certification:

-

CE ISO SGS

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

105 mm

-

Max.Bottle Height(mm):

-

328 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FAYGO

-

Voltage:

-

customerized

-

Dimension(L*W*H):

-

3.3X1X2.3

-

Weight (KG):

-

3000 KG

-

Warranty:

-

1

-

After-sales Service Provided:

-

Overseas service center available

-

Automatic:

-

Yes

-

Name:

-

automatic pet water bottle making machine

-

Type:

-

FG-4 PET bottle making machine

-

Capacity:

-

6500-7200

-

PLC:

-

MITISUBISHI Japan

-

Certification:

-

CE ISO SGS

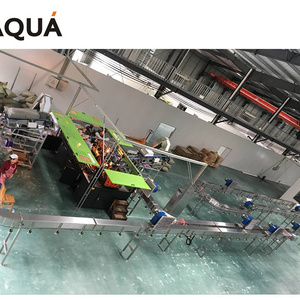

PET bottle manufacturing plant

FG-4 PET bottle manufacturing plant is a completely new generation of linear manufacturing plant , whose single-mold speed can reach 1800BPH. FG-4 has 4 cavities, production capacity is 7200BPH. It is developed totally independently, has our own intellectual property rights, and has obtained more than 13 national patents.

Product advantages of our pet water bottle manufacturing plant:

1)High speed: China first Linear PET bottle manufacturing plant whose single mold speed can reach 1800 BPH. FG4 has 4 cavities, production speed can reach 7200BPH.

2)Energy saving: The new modularized design make the machine work more efficient

|

Type |

FG-4 |

Mark |

||

|

Specifications of bottle |

Mould number(piece) |

4 |

|

|

|

maxi volume (mL) |

2000 |

|

||

|

maxi height (mm) |

328 |

|

||

|

maxi diameter (mm) |

105 |

|

||

|

Square bottle for max diagonal length (mm) |

115 |

|

||

|

preform Specifications |

Suitable inner bottle neck (mm) |

20-25 |

|

|

|

preform max length (mm) |

150 |

|

||

|

Capacity (bottles / hour) at 17 g 500mL |

7200 |

|

||

|

Electricity |

Install power (kw) |

51 |

|

|

|

Heating oven total power (kw) |

46 |

|

||

|

Heating oven actual power consumption (kw) |

26 |

|

||

|

Voltage / frequency (V / Hz) |

380v,50hz |

|

||

|

Allowed voltage fluctuation |

±10% |

|

||

|

HP Air |

Pressure(bar) |

30 |

|

|

|

Capacity(m³/min) |

4 |

|

||

|

Cooling Water |

Mold water |

pressure(bar) |

4-6 |

Water chiller 6HP |

|

Suitable temperature range (℃) |

6-13 |

|||

|

Flow (L / min) |

45 |

|||

|

Oven water |

pressure(bar) |

4-6 |

Water chiller

3HP

|

|

|

Suitable temperature range (℃) |

6-13 |

|||

|

Flow (L / min) |

22 |

|||

|

Machine Specification |

host machine dimension (m) length × width × height |

3.3*1*2.3 |

|

|

|

Weight (Kg) |

3200 |

|

||

Configuration of PET bottle manufacturing plant

1.Minimize distance of heating heats:

Heater distance in the heating oven is reduced to 38mm, compared with the conventional heating oven, it saves more than 30% electricity consumption.

2. Modularized design conception

Adopting modularized design concept, to make it convenient and cost-saving for the maintenance and changing spare parts

3. Efficient and soft perform inlet system

By rotary and soft preform inlet system, the speed of preform feeding is ensured meanwhile, the preform neck is well protected.

4.Servo driving and cam linking blowing section:

The unique cam linking system integrates movement of mold-opening, mold-locking and bottom mold-elevating in one movement, equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

1. Exploded bottles rejection unit

During the blowing process, if the bottle burst s , bad bottles can be automatically removed. This prevents the bad bottles from entering the filling machine.

2. H igh pressure air recovery Unit

After the water bottle blowing, high pressure air can be recycled and used again for the pre-blowing and machine physical movement .

3. Oven and preform temperature detection unit

Thermal sensing unit detects temperature in oven and temperature of heated performs . When the temperature does not reach the set blowing temperature , blowing workstation will alarm, not blown.

1. Stand-by engineers team to provide overseas installation and commissioning service.

2 1 year warranty. During warranty, we provide free of charge for repairing cost.

3. Lifetime maintenance. After-sales department can provide life long maintenance service.

We can also supply :