- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥99%

-

Packaging Type:

-

tube

-

Voltage:

-

220V/50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

1950*800*1850mm

-

Weight:

-

800 KG

-

Product name:

-

Small Automatic Tube Filling Machine

-

Machine name:

-

MIC-L45

-

Material:

-

Stainless Steel

-

Filling speed:

-

30-65 tubes/min

-

Filling volume:

-

3-75ml

-

Advantage:

-

Self tube loaded,Efficient and precise,Easy to operate and flexible

-

Motor:

-

1.5Kw

-

Maximum Tube Dia.:

-

60mm

-

Additional Function:

-

Piston filling

Quick Details

-

Machinery Capacity:

-

2400-2700BPH

-

Packaging Material:

-

Metal

-

Filling Material:

-

adhesives,AB glue, silicone sealant ,cream etc.

-

Filling Accuracy:

-

≥99%

-

Packaging Type:

-

tube

-

Voltage:

-

220V/50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

1950*800*1850mm

-

Weight:

-

800 KG

-

Product name:

-

Small Automatic Tube Filling Machine

-

Machine name:

-

MIC-L45

-

Material:

-

Stainless Steel

-

Filling speed:

-

30-65 tubes/min

-

Filling volume:

-

3-75ml

-

Advantage:

-

Self tube loaded,Efficient and precise,Easy to operate and flexible

-

Motor:

-

1.5Kw

-

Maximum Tube Dia.:

-

60mm

-

Additional Function:

-

Piston filling

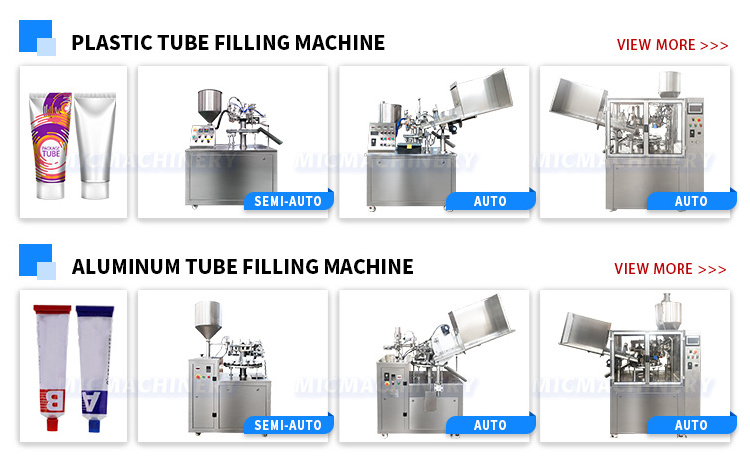

MIC-L45 small automatic silicone sealant tube filling machine is mainly used for aluminum and metal tube filling and sealing. It has been widely used in the fields of cosmetic, food and chemical etc. It is pneumatic controlled, with 1 filling head and tube tail folding stations. It has total 18 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, RTV silicone etc., are all applicable.

This machine is our new-design machine which used for filling cartridge tube.

It equipped with a hydraulic pressure machine to handle the high viscosity material.

The working progress is:

Putting the cartridge tube into the molds automatically/manually--Filling--Inserting cap--Output.Easy operation but high speed production.

|

Weight

|

800 Kg

|

|

Power

|

220V/50Hz

|

|

Motor

|

2.2 Kw

|

|

Dimension

|

1950*800*1850mm

|

|

Filling Quantity

|

3-20ml,15-75ml, 75-250ml

|

|

Capacity

|

30-35 pieces/minute

|

Hydraulic pressure machine

It is a dispersing machine equipment for high viscosity products

FILLING SYSTEM

Update use Servo Motor Driving Filling System for meeting high accurate filling volume. Especially speed up the filling speed and

make the filling process more steady.

CAP SORTING&FEEDING SYSTEM

The cap vibratory auto sorting and feeding cap into slideway one by one, prepare for next press capping process

CAPPING SYSTEM

The complete capping system for auto press cap into each cartridges.

TOUCH SCREEN OPERATE PANEL

Operator through touch screen control the machine each part running, as well adjust the running parameters.Include adjust the specific filling volume.

Hot Searches