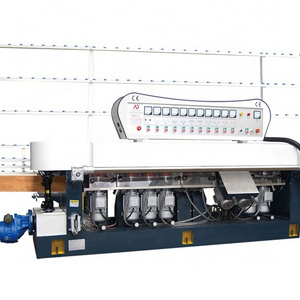

1. For flat glass straight line edging, corner and bottom edge grinding & polishing completed at one time.

2. All main part are cast iron and annealing treatment, machine more strong and stable.

3. Felt wheel polishing & digital display & pneumatic polishing are optional.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dragon Glass

-

Voltage:

-

380V/50Hz , or customized

-

Power:

-

19, 19KW

-

Dimension(L*W*H):

-

6800*1000*2500mm

-

Weight:

-

2700 kg

-

Product name:

-

Glass edge grinding machine

-

Min glass size:

-

80x80mm

-

Feature:

-

Easy to operate

-

Advantage:

-

Long life

-

After Warranty Service:

-

Video technical /Online

-

Process speed:

-

1 - 6m/min

-

Glass thickness:

-

3 - 25mm

-

After-sales Service Provided:

-

Online support/Field maintenance and repair service

-

Local Service Location:

-

Egypt/Turkey/Brazil/India/Russia/Japan/Ukraine/Uzbekistan

Quick Details

-

Machine Type:

-

Glass Edging Machine

-

Glass Thickness:

-

3-25 mm

-

Production Capacity:

-

1-6 M/MIN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dragon Glass

-

Voltage:

-

380V/50Hz , or customized

-

Power:

-

19, 19KW

-

Dimension(L*W*H):

-

6800*1000*2500mm

-

Weight:

-

2700 kg

-

Product name:

-

Glass edge grinding machine

-

Min glass size:

-

80x80mm

-

Feature:

-

Easy to operate

-

Advantage:

-

Long life

-

After Warranty Service:

-

Video technical /Online

-

Process speed:

-

1 - 6m/min

-

Glass thickness:

-

3 - 25mm

-

After-sales Service Provided:

-

Online support/Field maintenance and repair service

-

Local Service Location:

-

Egypt/Turkey/Brazil/India/Russia/Japan/Ukraine/Uzbekistan

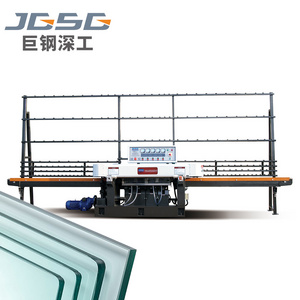

Products Description

Feature & Advantage

|

Model

|

|

DGEM9

|

|

|

|||

|

Min size glass

|

|

80 x 80mm

|

|

|

|||

|

Glass thickness

|

|

3 - 25mm

|

|

|

|||

|

Process speed

|

|

1 - 6m/min

|

|

|

|||

|

Power

|

|

19KW

|

|

|

|||

|

Weight

|

|

2700KG

|

|

|

|||

|

Dimension

|

|

6.8 x 1 x 2.5M

|

|

|

|||

Details Images

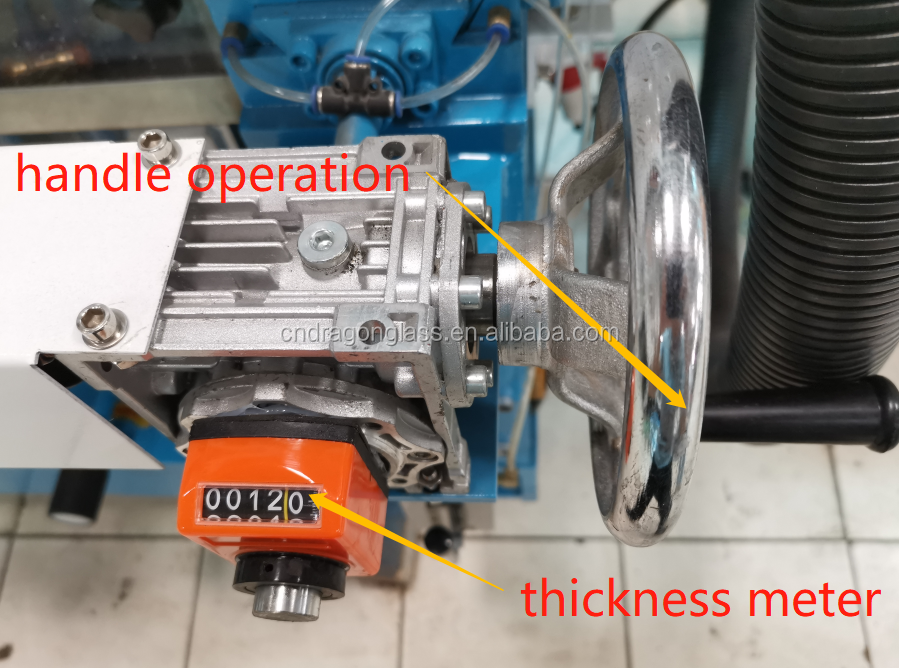

1. Glass thickness adjustment

Glass thickness adjust by handle, glass thickness showing on meter, few seconds can be finished the thickness adjustment.

2. Chain transfer system

Chain conveyor & solid type front pads, good for big size and heavy glass.

The support adopting fluency strips, glass will go through more fluency and steady.

At the front and end of the rail guide, there is a glass holder which can turning to hold the glass and make it move easily.

3. Lubrication system & Foot kick emergency button & Water pump power supply

Lubrication system, pull the oil pump the lubricating oil will come to every slider (motors base & rail guide base) and the rail guide, it will get maintain and longer life.

Foot kick emergency button, when meet some emergency problem, except the emergency button that on the control panel, you can use your foot to kick it to make the machine stop.

Water pump power supply also adopting waterproof one to insure it safety.

4. Cast iron & stainless-steel screws

All screw and nut are stainless steel one

5.Inlet and outlet system

Inlet and outlet pipes adopting PVC material, and the joint is removable which is easy for maintain.

6. Electric components adopting Schneider / CHNT brand.

All wires with lug for ensure electric safety, and all wires with mark to match every components so that it’s easy to maintain.

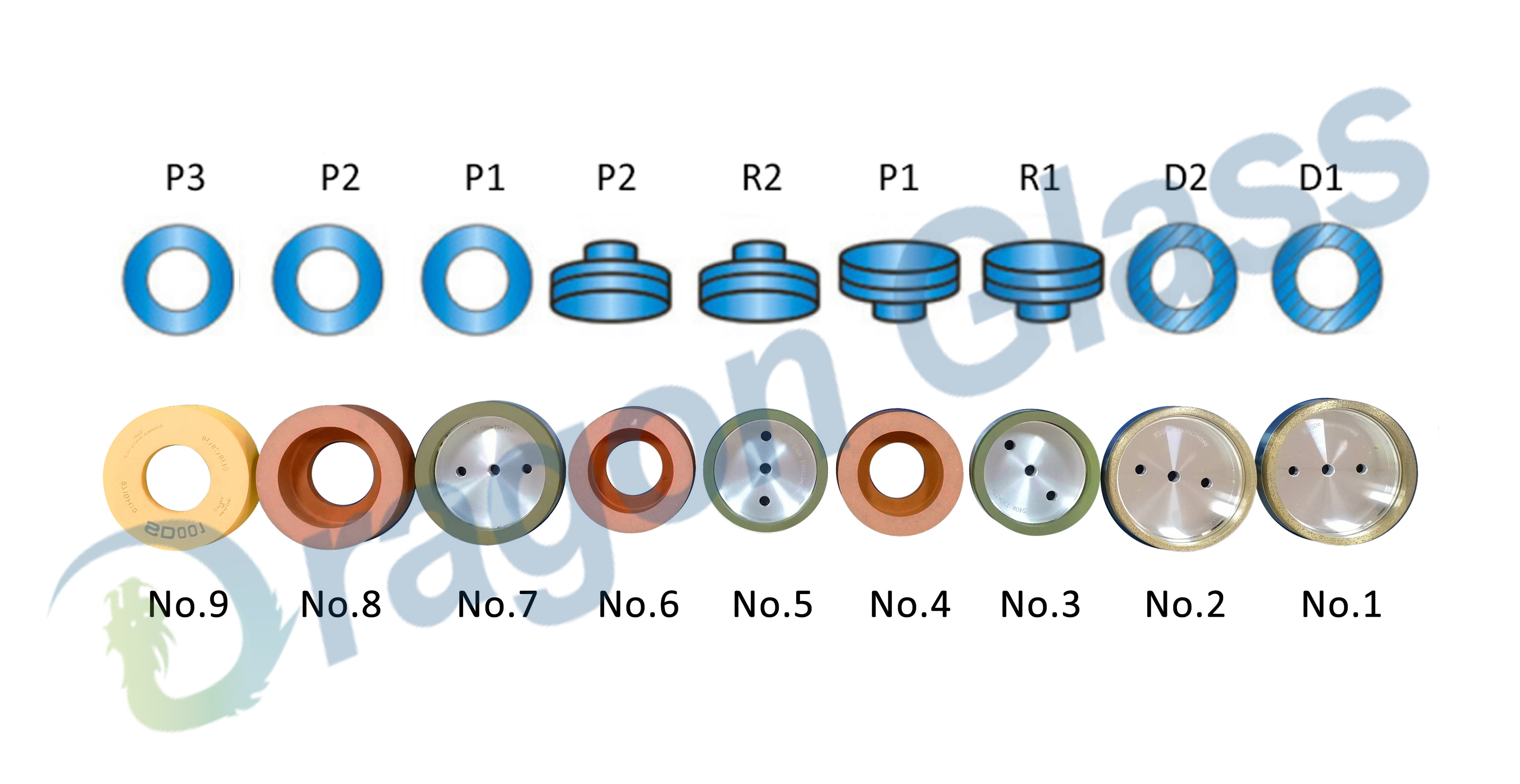

7. Motors and Wheels

Adopting professional edging motors, motors are stable and quiet.

5 wheels (motors / spindle) for bottom grinding & polishing

4 wheels (motors / spindle) for front & back chamfering

5 wheels (motors / spindle) for bottom grinding & polishing

4 wheels (motors / spindle) for front & back chamfering

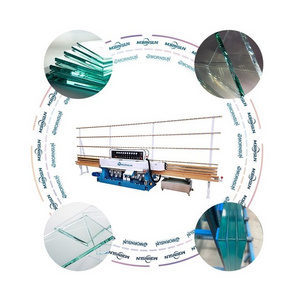

8. The picture of Glass finish edging

Related Products

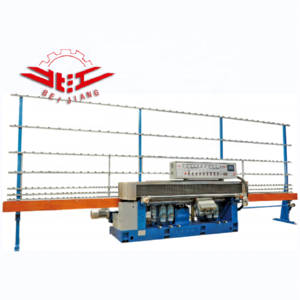

Technical Parameters of other glass edging machine in the same series

|

Model

|

DGEM11

|

DGEM9-45°

|

DGEM11-45°

|

|

Min size glass

|

80 x 80mm

|

80 x 80mm

|

80 x 80mm

|

|

Glass thickness

|

3 - 25mm

|

3 - 25mm

|

3 - 25mm

|

|

Glass angle

|

/

|

0°- 45°

|

0°- 45°

|

|

Process speed

|

1 - 6m/min

|

1 - 6m/min

|

1 - 6m/min

|

|

Power

|

23.5KW

|

19KW

|

23.5KW

|

|

Weight

|

3200KG

|

3000KG

|

3500KG

|

|

Dimension

|

7.5 x 1 x 2.5M

|

6.8x1.2x2.5M

|

7.5 x 1.2 x 2.5M

|

Company Introduction

1. Engineer team more than 25 years experience , especially specialized in all glass grinding machines

2. Most of parts use good quality one and perfect process to improve the quality and reliability of machines

3. Good service , installation & training & repair service available in any time

4. OEM available (LOGO ,outlook, configuration )

2. Most of parts use good quality one and perfect process to improve the quality and reliability of machines

3. Good service , installation & training & repair service available in any time

4. OEM available (LOGO ,outlook, configuration )

Packing&Shipping

FAQ

1. What's the guarantee?

2. Why your price is higher than another company or factory?

* We use world famous brands of electrical parts with longer usage life. Our strong engineers have more than 20 years of R&D experience in this field, we always use mature structure/design of our machines.

3. How long is the delivery time?

* Normally is 25 to 45 days. If urgent,we will produce as fast as we can.

4. How about the installation and debug?

* We will make Instruction with detail photos,video to teach you,if need engineer,will send to you.

* The whole set of machine warranty period is 1 year.

* 24 hours technical support by email or calling.

* We will provide the consumable parts at an agency price.

* 24 hours technical support by email or calling.

* We will provide the consumable parts at an agency price.

2. Why your price is higher than another company or factory?

* We use world famous brands of electrical parts with longer usage life. Our strong engineers have more than 20 years of R&D experience in this field, we always use mature structure/design of our machines.

3. How long is the delivery time?

* Normally is 25 to 45 days. If urgent,we will produce as fast as we can.

4. How about the installation and debug?

* We will make Instruction with detail photos,video to teach you,if need engineer,will send to you.

Hot Searches