Boron nitride materials are chemically and have relatively good thermal conductivity, low thermal expansion and microwave clarity. Boron nitride can be quickly and easily machined as well. Moreover, glass, salts and the rest of liquid metals are non-wetting. This ensures that neither of these compounds can be moistened, and it is far more immune to chemical assaults. BN is self-lubricating as well.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UNIPRETEC

-

Color:

-

White, Grey, Dark Grey

-

Density:

-

1.5 - 3.0 g/cm3

-

Max. Working Temp.:

-

900 - 2,000 °C

Quick Details

-

Material:

-

Boron Nitride

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

customized

-

Brand Name:

-

UNIPRETEC

-

Color:

-

White, Grey, Dark Grey

-

Density:

-

1.5 - 3.0 g/cm3

-

Max. Working Temp.:

-

900 - 2,000 °C

Material Introduction

Hexagonal Boron Nitride Ceramics

Product Features

Excellent Electrical Insulator

Max. 2000 °C Use Temp.

High Thermal Shock Resistance

Low CTE

Low Wetted by Molten Metals

Easy Machinability

Material Properties

|

ITEM

|

UNIT

|

BN-2000

|

BN-2300

|

BN-2800

|

BN-3000

|

|

Main Content

|

-

|

BN>99%

|

BN+Al

2

O

3

|

BN+AlN

|

BN+ZrO

2

|

|

Color

|

-

|

White

|

Light Grey

|

Dark Grey

|

Dark Grey

|

|

Density

|

g/cm

3

|

1.95-2.00

|

2.25-2.35

|

2.75-2.85

|

2.90-3.00

|

|

Flexural Strength

|

Mpa

|

30

|

65

|

85

|

90

|

|

Compressive Strength

|

Mpa

|

55

|

145

|

205

|

220

|

|

Electrical Resistivity

|

Ω·cm

|

>10

14

|

>10

13

|

>10

13

|

>10

12

|

|

Max. Use Temp. (Air)

|

℃

|

900

|

1,000

|

1,000

|

1,000

|

|

Max. Use Temp. (Vacuum)

|

℃

|

1,900

|

1,750

|

1,800

|

1,750

|

|

Max. Use Temp. (Inert)

|

℃

|

2,000

|

1,750

|

1,800

|

1,750

|

|

Thermal Conductivity

|

W/m.K

|

35

|

30

|

85

|

30

|

|

CTE (25 - 1,000 ℃)

|

10

-6

/K

|

1.5

|

2

|

2.8

|

3.5

|

∆ The above data is offered for reference and comparison only, exact data will vary depending on manufacturing method and part configuration.

Applications

Amorphous Alloy Strip Producing

Metal Powder Gas Atomization

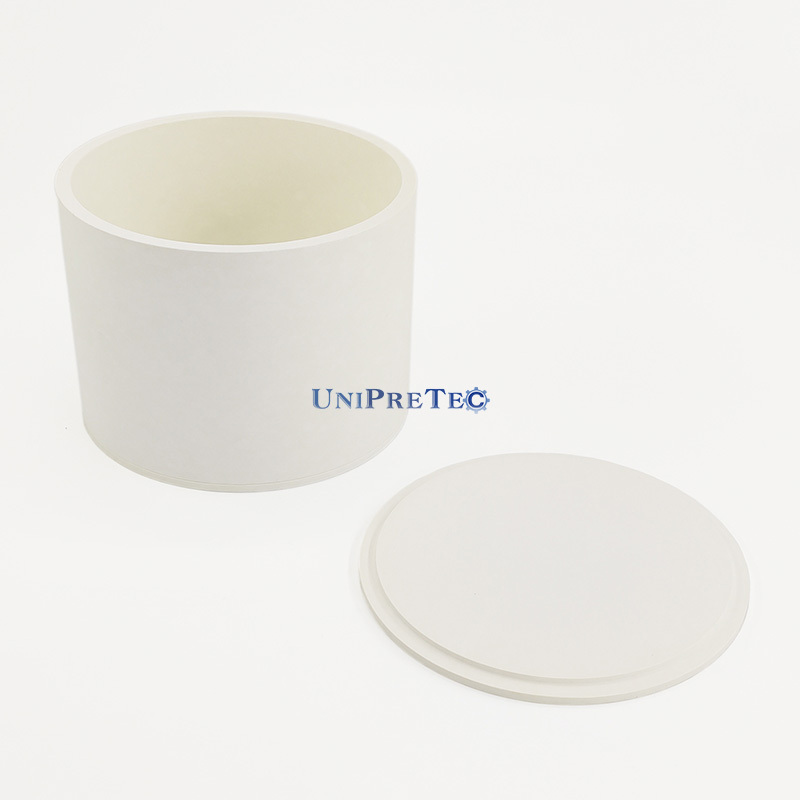

Melting Crucibles and Liners

Vacuum Furnace Parts

Aerospace

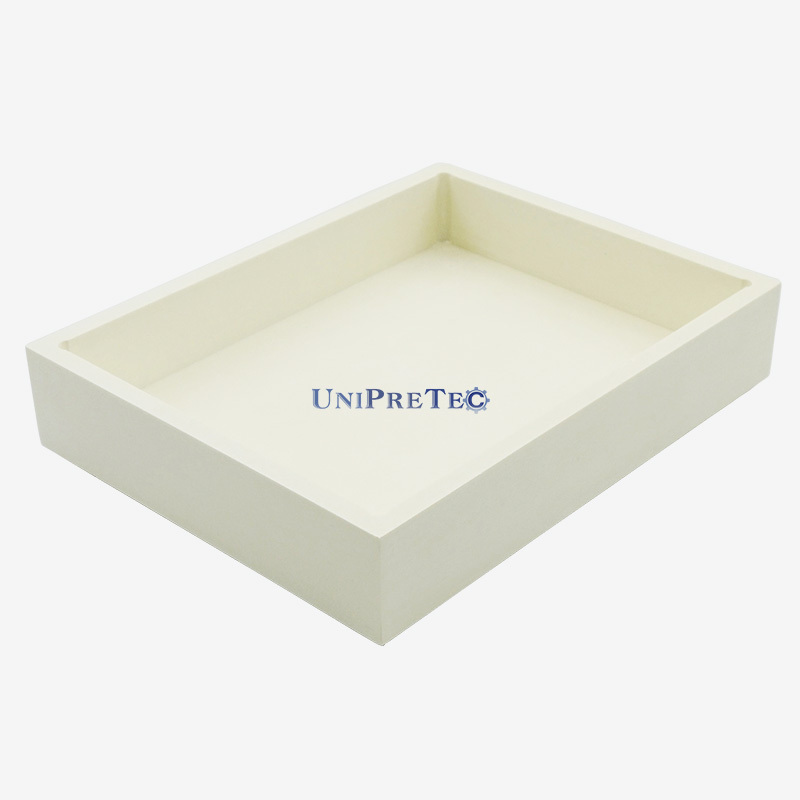

Sintering Trays and Setters

Inspection

About Us

UNIPRETEC is a representative technical ceramic company in China. Relying on the technical team with more than 10 years of experience and the cooperation of well-known domestic colleges and institutions, our company covers the manufacturing and sales of oxide, nitride and carbide ceramic products. Based on the research in the advanced ceramic industry, our company is good at providing suitable products and suggestions flexibly according to customers' applications and needs. For many years, our company has focused on meeting the needs of customers from all over the world. Many praises from customers and partners have been encouraging UNIPRETEC to move forward and develop.

"Simple things into very complex, can find new areas; Read the complex phenomenon is very simple, can be found that the new law." - - - - - -Isaac Newton

Hot Searches