Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Groove depth:

-

11mm

-

L/D:

-

28-60

-

Main motor power:

-

55-90KW

-

Screw rotating speed:

-

400/500/600rpm/min

-

Output:

-

150-400kg/h

-

Design:

-

Customized

-

Main motor:

-

SIEMENS

Quick Details

-

Screw Design:

-

Double-screw

-

Place of Origin:

-

Jiangsu, China

-

Screw Diameter:

-

62.4mm

-

Groove depth:

-

11mm

-

L/D:

-

28-60

-

Main motor power:

-

55-90KW

-

Screw rotating speed:

-

400/500/600rpm/min

-

Output:

-

150-400kg/h

-

Design:

-

Customized

-

Main motor:

-

SIEMENS

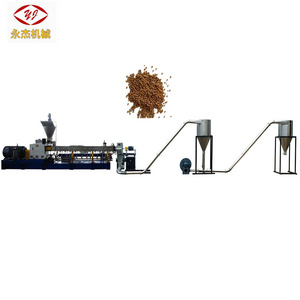

ABS PS PP PE granules beads particle twin screw making extruder machine composite wood plastic wpc extrusion machine

|

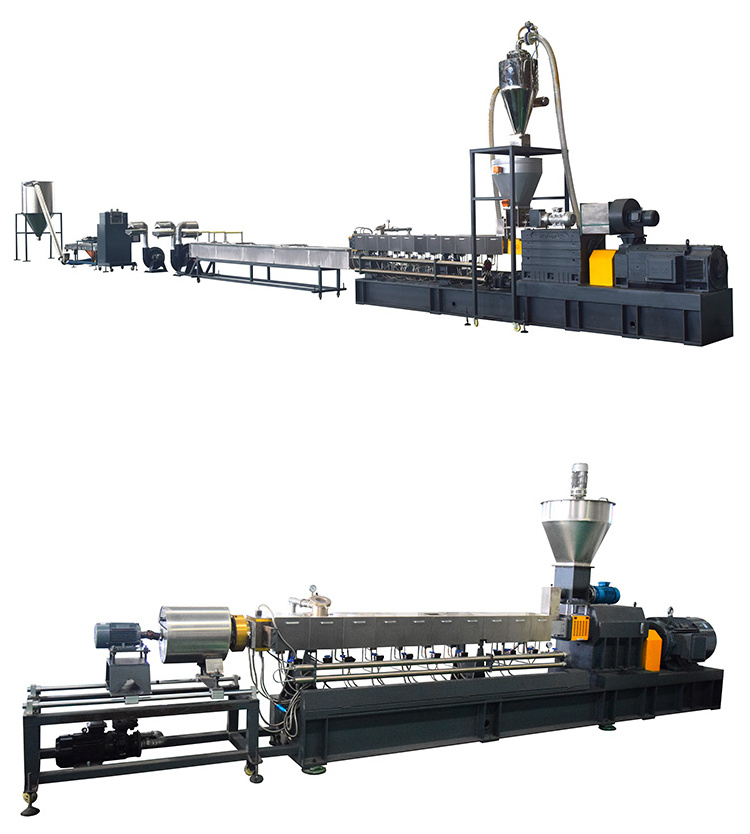

>>Gearbox

Reduction transmission: High torque gearbox

|

|

> >Screw Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. |

|

> >Barrel

By means of the replaceable screw barrel sections, the

processing sections is devided into individual zones. The barrels are heated electrically. In addition, the barrels are provided with longitudinal bores for cooling with water. Uniform temperature distribution, namely on the circumference of the eightshaped barrel bore, is achieved by a reverse forceflow temperature

|

|

Model /Parameter |

Screw Diameter/mm |

Groove depth/mm |

L/D |

Main motor power/KW |

Screw rotating speed(rpm/min) |

Output(kg/h) |

| MT-20 | 21.7 | 3.85 | 28/60 | 4 | 600 | 5-15 |

| MT-26 | 25 | 4.1 | 28/60 | 5.5-10 |

600 |

10-40 |

| MT-36 | 35.6 | 6 | 28-60 | 15-22 | 600 | 15-80 |

| MT-40 | 41 | 7 | 28-60 | 30-37 | 500/600 | 50-150 |

| MT-50 | 50.5 | 9 | 28-60 | 37-55 | 500/600 | 80-200 |

| MT-60 | 60 | 10 |

28-60 |

45-75 | 400/500/600 | 100-300 |

| MT-65 | 62.4 | 11 | 28-60 | 55-90 | 400/500/600 | 150-400 |

| MT-75 | 71 | 12 | 28-60 | 110-250 | 400/500/600 | 250-800 |

| MT-95 | 92 | 16.3 | 28-60 |

200-315 |

400/500/600 | 650-1500 |

| MT-135 | 133 | 23.5 | 28-48 | 600 | 300/400 | 1500-3000 |

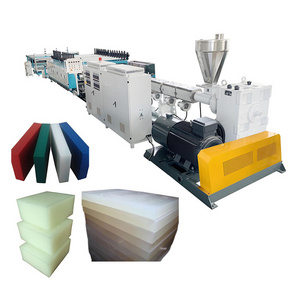

application for plastic

Suitable for: