- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, 390*190*190mm,240*115*90mm,240*115*50mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BRK

-

Voltage:

-

110-440V

-

Dimension(L*W*H):

-

7100x1500x3000mm host machine

-

Weight (KG):

-

6200 kg

-

Block Type:

-

Hollow Solid Paver Block Curbstone

-

Advantage:

-

Automatic Hydraulic Block Production Line

-

Pallet size:

-

900*700MM

-

Model:

-

QT6-15

-

Molding cycle:

-

15-20S

-

Machine Type:

-

Fully Automatic Brick Block Making Machine

-

Power:

-

28.75KW

-

Vibration frequency:

-

4600r/min

-

Pressure:

-

16-22mpa

-

Control mode:

-

PLC full-automatical control

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

ement, sand, gravels, crushed stone powder, slags, fly ash

-

Production Capacity (Pieces/8 hours):

-

88000 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, 390*190*190mm,240*115*90mm,240*115*50mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BRK

-

Voltage:

-

110-440V

-

Dimension(L*W*H):

-

7100x1500x3000mm host machine

-

Weight (KG):

-

6200 kg

-

Block Type:

-

Hollow Solid Paver Block Curbstone

-

Advantage:

-

Automatic Hydraulic Block Production Line

-

Pallet size:

-

900*700MM

-

Model:

-

QT6-15

-

Molding cycle:

-

15-20S

-

Machine Type:

-

Fully Automatic Brick Block Making Machine

-

Power:

-

28.75KW

-

Vibration frequency:

-

4600r/min

-

Pressure:

-

16-22mpa

-

Control mode:

-

PLC full-automatical control

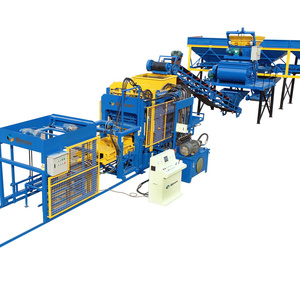

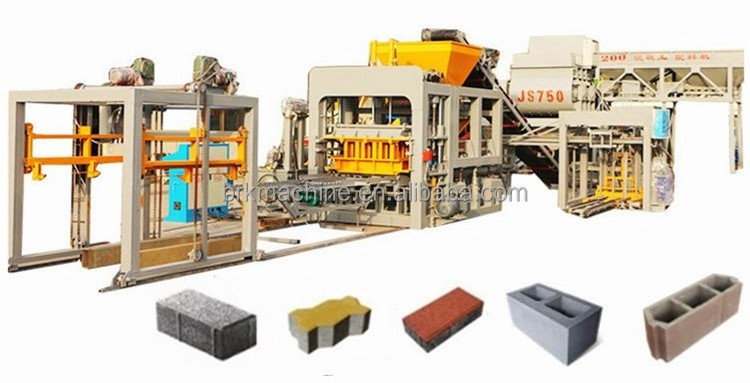

QT6-15 cost-effective Hydraulic Hollow Brick Block Full automatic cement block moulding machine

Description:

QT6-15 cost-effective Hydraulic Hollow Brick Block Full automatic cement block moulding machine, it is full automatic can make all types of hollow blocks, solid blocks, curbstones, pavers and so on. adopts advanced hydraulic system and vibration system, can ensure the block quality good and the working noise

low. Blcok making machine with SCHNEIDER,SIEMENS, OMRON, CALYCA and so on to make sure our block making machine with high quality and keep our machine work more stable.

Main technical parameters:

| Model | QT6-15 |

| Rated pressure | 16Mpa |

| Dimension | 7100*1500*3000mm |

| Forming Cycle | 15-20s |

| Vibration form | Platform vibration |

| Weight | 6200kg |

| Power | 28.75KW |

| Worker | 2-3 Worker |

| Working area | 1500m |

| Pallet size | 900x680mm |

| Related Accessories | 100T Silo, PLD1200 Batching, JS750 mixer, Forklift, 2000pcs Pallet |

Main Advantages:

QT6-15 cost-effective Hydraulic Hollow Brick Block Full automatic cement block moulding machine

1. This model block making machine completely use PLC systems, human-computer interface and Chinese/English menu.Hydraulic integrated automatic control, simple and reliable operation

2. The electricity motor, in mixer and host machine, we use Germany Siemens motor.

3. The switches, we select the France Schneider brand, it could assure the working process smoothly.

4.The control system use computer control and man-machine interface.Electrical equipment apply the well-known brands from Japan and Germany, like Japan Mitsubishi.

5. Mould can be changed quickly,The block mould use the newest high temperature carburizing heat treatment technology, in order to prolong the life of block mould.

6. Advanced press and vibration forming technology can completely liquefy and exhaust the concrete within 2-3 seconds to ensure the high density of the product. It is especially suitable for the production of high-strength standard bricks, which can be stacked after forming.

Production capacity:

| Block | Size/mm | Moulding Cycle | Qty/Mould | Qty/Hour | Qty/8Hours | |

| Hollow Block | 400x200x200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520 pcs | |

| Hollow Block | 400x150x200 | 15-20 s | 7pcs | 1260-1680pcs | 10080-13440pcs | |

| Hollow Block | 400x100x200 | 15-20 s | 11pcs | 1980-2640 pcs | 15840-21120 pcs | |

| Hollow Block | 400x150x200 | 15-20 s | 7pcs | 1260 - 1680 pcs | 10080-13440 pcs | |

| Poroue Block | 240x115x90 | 15-20 s | 15pcs | 2700-3600 pcs | 21600-28800 pcs | |

| Solid Block | 240x115x53 | 15-17 s | 30pcs | 6300-7200 pcs | 50400-57600pcs | |

| Paver | 225x112.5x60 | 20-25 s | 15pcs | 2160-2700 pcs | 17280-21600 pcs |

QT6-15 cost-effective Hydraulic Hollow Brick Block Full automatic cement block moulding machine

Raw materials are generally cement, sand, gravels, crushed stone powder, slags, fly ash, ect, depending on customers' choice.

A. 8-10% cement, 30-40% sand, 50-60% crushed stoneB. 8-10% cement, 30% flyash, 60% sand or stone powder The diameter of sand and stones need to be less than 15mm, if produce paver interlocking brick, need color iron.

Customer Site:

Our service:

Pre-sale service

1.Professional advice on raw material and site selection.

2.Seletion of the most suitable machine.

3.24 hours online service.

4.Welcome to visit our factory at any time .

On sale service

1.Update the production scheduling in time

2.Quality supervision

3.Product acceptance and testing

4.Shipping on time

After sale service

1.Free online guidance and tutorials

2.Professional engineer training service

3.One year quality guarantee period.

4.Regular return visits to customer usage

Packing and deliver :

Packing shall be wrapped with plastic film or according to the customer's require.

1. The whole brick machine production line is mainly full container shipping,

2. Wrap the whole brick machine with plastic film before shipment to prevent water or moisture,

3. Then load the brick machine into the container with a forklift,

4. During loading, tighten the machine with the reinforcing ring in the container to avoid damage caused by transportation bumps on the brick machine.