- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.25

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2700*1200*1600

-

Power (kW):

-

22

-

Weight (KG):

-

2500 KG

-

Product name:

-

open rubber mixing machine mixing mill for rubber

-

Function:

-

rubber mixing mill machine

-

Name:

-

Rubber Mixing Mill Machine

-

Application:

-

Mixing Rubber

-

Keywords:

-

Roller Rubber Mixer

-

Type:

-

Open Mixing Mill

-

Roller diameter:

-

180MM

-

Usage:

-

Silicone Rubber Mixing

-

Mixing mill machine for uncrurred rubber:

-

Mixing Mill Machine

-

Machine type:

-

RUBBER MICING MILL

Quick Details

-

Diameter of Roll(mm):

-

300 mm

-

Rotation Speed of Front Roll(rpm):

-

15 - 16 rpm

-

Length of Roll(mm):

-

800 mm

-

Roll Ratio(Front/Back):

-

1:1.25

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2700*1200*1600

-

Power (kW):

-

22

-

Weight (KG):

-

2500 KG

-

Product name:

-

open rubber mixing machine mixing mill for rubber

-

Function:

-

rubber mixing mill machine

-

Name:

-

Rubber Mixing Mill Machine

-

Application:

-

Mixing Rubber

-

Keywords:

-

Roller Rubber Mixer

-

Type:

-

Open Mixing Mill

-

Roller diameter:

-

180MM

-

Usage:

-

Silicone Rubber Mixing

-

Mixing mill machine for uncrurred rubber:

-

Mixing Mill Machine

-

Machine type:

-

RUBBER MICING MILL

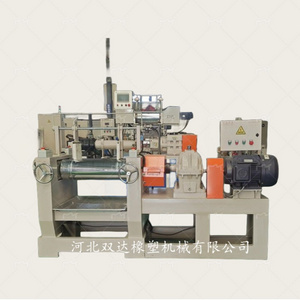

open rubber mixing machine mixing mill for rubber

our company provides rubber mixing mill for various application & production capacity

size of roller : 6 inch , 10inch , 12 inch , 14 inch , 16inch , 18 inch , 22 inch

Construction of rolls: drilled, bored, grooved, corrugated

Rubber mix mill mainly consists of machine base, machine frame, rolls, drive system, lubricating device, heating and cooling device, roll gap adjusting device, safety brake device, motor and retarder etc.

It is mainly used in following cases for rubber products factory: natural rubber refining, raw rubber and compound ingredient mixing, warming refining and sheeting of glue stock.

Main Features

1. The roller is made of alloy chilled cast iron (including separation cast or integrated alloy type). Their surfaces are hard and wear resistance

2.Rollers are divided into the hollow roll and drilled roll. The hollow roll(hollow roll inner cavity is bored , usually spraying

in bored cavity is adopted for heating and cooling ). The hollow roll surface can be machined into smooth roll , whole smooth roll ,partial grooved roll, welded up alloy roll and so on . For high cooling or heating speed , circumferential drilled roll can be selected

3.The roll is supported on both end by double row spherical bearings . Large machine adopts double bearing . so it has advantages of running smoothly , energy saving , low noise and long service life

4.All series mill are equipped with safety device according to the new station stands , in order to protect the main parts from damaged

5.The roll bearing lubrication : grease lubrication and oil lubrication for order

6.The driving part adopts nylon pin coupling to prevent main parts from being damaged due to overload of transmission part

7.The reducer adopts the hardened gear teeth surface reducer . It has low noise , high transmission efficiency and long service life

8.The base is integral type, the transmission mode is closed transmission , so it is safe and easy for use

9.The user can select the stock blender according to the process

| model | yw300 |

| roller diameter | 300 mm |

| roller working length | 300 mm |

| front roll linear speed | 15.1 m/min |

| friction ratio of rollers | 1:1.27 |

| max gap | 8 mm |

| motor | 22 kw |

| batch capacity | 15-20 kgs |

| machine size | 3580*1550*1695 mm |

| machine weight | about 3000kg |