Machining Range:∅2500*10000

Precision:0.01

|

Product Name

|

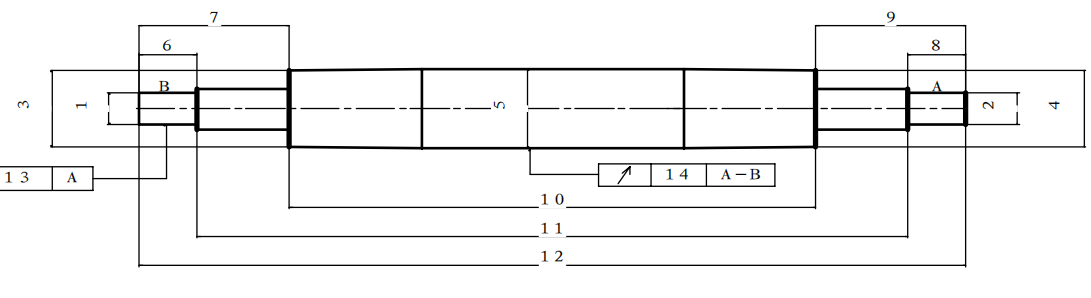

Machining Steel Food Container Printing Machine Conveyor Gravity Roller Parts

|

|

Material

|

1.Stainless steel

2.Carbon steel

3.Aluminum alloy

4.customized

|

|

Surface treatment

|

1.Galvanized

2.Textile printing and dyeing industry

3.Soldering

4.Rubber

5.Chrome

6.Grinding

7.Polyurethane

|

|

Applicable industry

|

1.Printing industry

2.Textile printing and dyeing

3.Logistics and Conveying

4.Packaging industry

5.Mining industry

6.Film covering machinery

7.Agricultural machinery

8.Other

|

|

Dimensions

|

Customized service according to your drawings or samples for tube 127mm conveyor roller

|

|

Diameter & MOQ

|

Within 200mm — 100pcs

200mm-300mm — 50pcs

300mm-500mm — 20pcs

Above 500mm — 1pcs

The data just for reference, welcome negotiate with us based your need.

|

|

One-stop Service

|

Custom-made, fabrication, assembly and delivery for tube 127mm conveyor roller

|