- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ACE

-

Model Number:

-

ACE-ZZB-R177

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

50 /60 Hz

-

Outlet Size:

-

25mm/40mm/50mm/80mm/100mm

-

Power:

-

1.5KW-22KW

-

motor:

-

ABB/Domestic

-

Material:

-

Stainless Steel 304/ SS316L

-

Sealing:

-

EPDM/PTFE

-

Motor:

-

ABB/Domestic

-

Flow rate:

-

0-200T

-

Device:

-

SS motor cover, trolley, etc

-

Speed:

-

0-1000RPM

-

Type:

-

Rotor pump/Rotary Pump/Lobe Pump

-

Usage:

-

Transfer High Viscosity Liquid

-

Keyword:

-

Fuel Transfer Pump

Quick Details

-

Application:

-

Drinking water treatment, Family Homes, Food and Beverage Industry, Industrial Boilers, Industrial Utilities, Machining, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Washing and Cleaning

-

Pressure:

-

Low Pressure

-

Voltage:

-

220V/380V/440V

-

Brand Name:

-

ACE

-

Model Number:

-

ACE-ZZB-R177

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

50 /60 Hz

-

Outlet Size:

-

25mm/40mm/50mm/80mm/100mm

-

Power:

-

1.5KW-22KW

-

motor:

-

ABB/Domestic

-

Material:

-

Stainless Steel 304/ SS316L

-

Sealing:

-

EPDM/PTFE

-

Motor:

-

ABB/Domestic

-

Flow rate:

-

0-200T

-

Device:

-

SS motor cover, trolley, etc

-

Speed:

-

0-1000RPM

-

Type:

-

Rotor pump/Rotary Pump/Lobe Pump

-

Usage:

-

Transfer High Viscosity Liquid

-

Keyword:

-

Fuel Transfer Pump

Automatic Gear Pump For Olive Petrol Diesel Fuel Oil Kerosene Transfer

22 Years Of Experience 3–7

days delivery

.

Reasonable Price And Best Service, CE Certificated Products

Advanced Technology.

2 Years Warranty

.

Video

Product Description

Description:

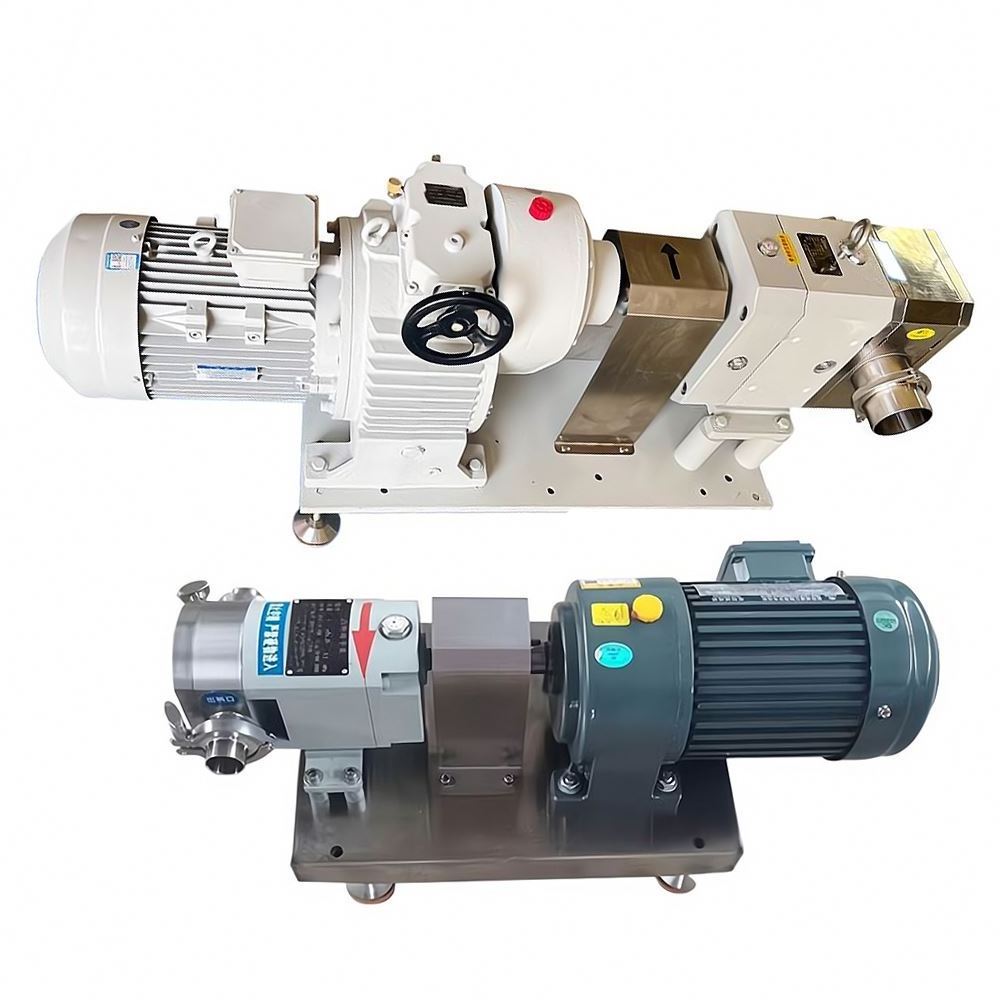

Rotary lobe pumps are positive-displacement type pumps that use two or more lobes rotating around parallel shafts in the pump’s body to move liquids. They are widely used in the hygienic processing industries, including food & beverage processing and Chemical.

|

Product Name:

|

Factory Price Sanitary Stainless Steel Food Grade Rotor Rotary Lobe Pump For Syrup Honey pump Chocolate pump

|

|

|

Description:

|

Designed according to 3A standard, widely used for transfer viscous media in the food-processing, cosmetics and industries.

|

|

|

Construction:

|

Horizontal Ace series, diffirent rotor shapes(single rotro,tri-lobe rotors and butterfly type rotors)

|

|

|

Material:

|

SS304/SS316

|

|

|

Seal Material:

|

EPDM (Standard, approval)

|

|

|

Max. Flow:

|

43000Liter/h

|

|

|

Max.pressure:

|

10bar

|

|

|

Speed

|

1-1000 rmp

|

|

|

Rotor Type:

|

2-leaves, 3-leaves, butterfly, signal butterfly

|

|

|

Mechanical seal:

|

SIC/SiC/EPDM(Standard)

|

|

|

Motor power:

|

0.75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, …22KW

|

|

|

Sealing option:

|

Sanitary single mechanical seal/Double mechanical seal with cooling system

|

|

|

Voltage:

|

220V, 380V(110-480v)

|

|

|

Motor:

|

ABB, Siemens,Our Domestic Brand,50hz/ 60hz

|

|

|

Surface treatment:

|

Inner polished and Sandblast outside

|

|

|

connection:

|

Clamp, Thread, weld, Flange

|

|

|

Availably standard:

|

DIN, SMS, 3A, RJT, ISO/IDF

|

|

|

Operated:

|

Electic

|

|

|

Application scope:

|

Dairy, food, beverage, pharmacy, cosmetic, etc

|

|

|

Packaging Details:

|

Plywood case

|

|

|

Delivery details:

|

Usually within1-7 days after receiving T/T down payment

|

|

|

We can customize the Lobe Pump according to customer requirements.

|

|

|

|

Model:

|

Capacity (L/100R)

|

Speed (RPM)

|

Flow (L/Hour)

|

Power(kw)

|

|

ACE-3

|

3

|

200-500

|

300-800

|

0.55

|

|

ACE-6

|

6

|

200-500

|

650-1600

|

0.75

|

|

ACE-8

|

8

|

200-500

|

850-2160

|

1.5

|

|

ACE-12

|

12

|

200-500

|

1300-3200

|

2.2

|

|

ACE-20

|

20

|

200-500

|

2100-5400

|

3

|

|

ACE-30

|

30

|

200-400

|

3200-6400

|

4

|

|

ACE-36

|

36

|

200-400

|

3800-7600

|

4

|

|

ACE-52

|

52

|

200-400

|

5600-11000

|

5.5

|

|

ACE-66

|

66

|

200-400

|

7100-14000

|

7.5

|

|

ACE-78

|

78

|

200-400

|

9000-18000

|

7.5

|

|

ACE-100

|

100

|

200-400

|

11000-22000

|

11

|

|

ACE-135

|

125

|

200-400

|

15000-30000

|

15

|

|

ACE-160

|

160

|

200-400

|

17000-34000

|

18.5

|

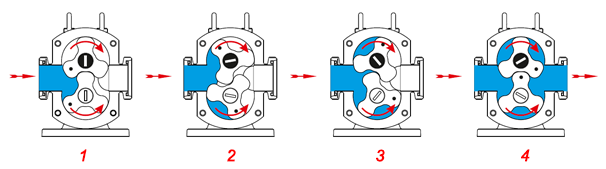

Working Principle of Rotary Lobe Pump:

The rotary lobe pumps we also called them lobe rotor pumps. They are one popular transfer pump to conveying the food, beverage, pulp and paper, chemical, pharmaceutical and so on. The rotor lobe pump relies on two synchronously rotating rotors that generate suction (vacuum) at the inlet during the rotation. Thereby sucking in the material to be conveyed. Both rotors split the rotor chamber into different spaces. Then operate in the order of 1-2-3-4. The medium is delivered to the discharge port. In this cycle, the medium (material) is continuously transported out by the source.

Different Kind of Lobe Options for the Rotor Lobe Pump

1.Single Lobed Rotor:

More suitable for conveying media which containing large granular materials. The breaking rate of large granular materials is low. But on other hand it is not popular one for used, Because its pulsation is large and pressure is low, also the volume is small for the space of transferred materials.

2. Two-Lobed Rotor (Butterfly Rotor)

More suitable for conveying media which containing small and medium-size granular materials. The breaking rate to these materials is low and getting slightly pulsating. The volume is a little less than three-lobed rotor for the space of transferred materials.

3.Three-Lobed Rotor

It is widely used one rotor. The volume is bigger than other type of rotors for the space of transferred materials. Also each performance is higher than other rotors. Just it has a certain rate of breakage to the particulate materials on the transport way.

4.Multi-Lobed Rotor(4-12)

The volume is more smaller for the space of transferred materials and breaking rate more higher when the quantity of rotary vane of rotor be increased, . Just the transport way more stable.

Character:

1,There Is A Certain Gap Between Rotor And Rotor, No Friction Coefficient,So Pump Have A Long Service Life Time.

2, It Is Easy To Install And Disassemble,And It Is Convenient To Maintain, Clean .There Is Less Wearing Parts.

3, High Efficiency And Energy Saving, Stable Transportation, Low Failure Rate, No Leak Sealing And Low Noise.

4, The Viscosity Of The Transportable Medium Is ≤2000000 Cp, And The Pump Can Transfer Slurry Containing 70% Solids.

5, It Can Transport Gas, Liquid And Solid Three-Phase Mixture Materials.

6, With Vfd, The Flow Can Be Adjusted At Will, And The Pump Can Be Used As A General Metering Pump.

7, If Need,We Can Do The Pump With Heating Jacket.

8, Applicable Temperature: -50 °C -250 °C.

9, Types Of Inlet/Outlet Connection: Flange Joint,Threaded Connection; Quick Connection.

10,Seal Type: Mechanical Seal And Packing Seal.

2, It Is Easy To Install And Disassemble,And It Is Convenient To Maintain, Clean .There Is Less Wearing Parts.

3, High Efficiency And Energy Saving, Stable Transportation, Low Failure Rate, No Leak Sealing And Low Noise.

4, The Viscosity Of The Transportable Medium Is ≤2000000 Cp, And The Pump Can Transfer Slurry Containing 70% Solids.

5, It Can Transport Gas, Liquid And Solid Three-Phase Mixture Materials.

6, With Vfd, The Flow Can Be Adjusted At Will, And The Pump Can Be Used As A General Metering Pump.

7, If Need,We Can Do The Pump With Heating Jacket.

8, Applicable Temperature: -50 °C -250 °C.

9, Types Of Inlet/Outlet Connection: Flange Joint,Threaded Connection; Quick Connection.

10,Seal Type: Mechanical Seal And Packing Seal.

Lobe Pump Scope Of Application.

Food:

Wine, Olive Oil, Vegetable Oil, Molasses, Pressed Olive Waste, Fermented Grapes, Glucose, Tomato Concentrate, Chocolate.

Industrial:

Sludge, Slurries, Manure, Effluent, Crude Oil, Glue, Inks, Paint, Fuel oil,

Mining:

Bentonite, Ceramic Slips, Calcium Carbonate.

Oil & Gas:

Seawater, Crude-Oil products, Oily Sludge, Marine spills, Mud.

Wastewater:

Membrane Bioreactor Filtration (MBR), Effluent, Sewage,

Details Images

Packaging & Shipping

We are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require

* Strict packing process to ensure the safety and completeness of the goods

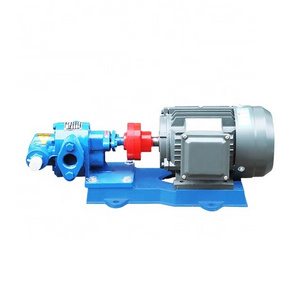

Other pumps

Screw pump

Single screw pump is used in all fields widely to feed kind of medium, running at a constant pressure continuously, without pulse and damage when feeding medium and change the gauging aim through adjusting rotation speed.

Homogenization pump

The machine disperses, shears and emulsifiers the material in shortest time, and the diameter range of the particles gets smaller so that fine and stable produced.

Centrifugal pump

Centrifugal pump is a kind of high efficient and economical pump, because it can meet the requirements of health and soft treatment of products, and has chemical stability, so it is only suitable for most of the health industry.

Certifications

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in a plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend, and we sincerely do business and make friends with them, no matter where they come from.

Contact Us

Hot Searches