- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

x-ray

-

Product Name:

-

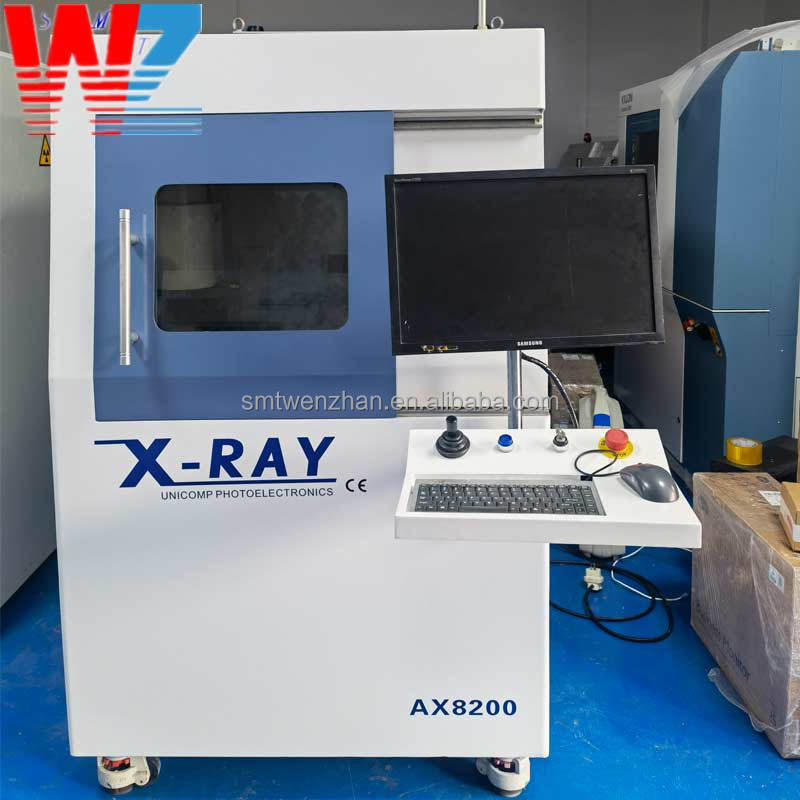

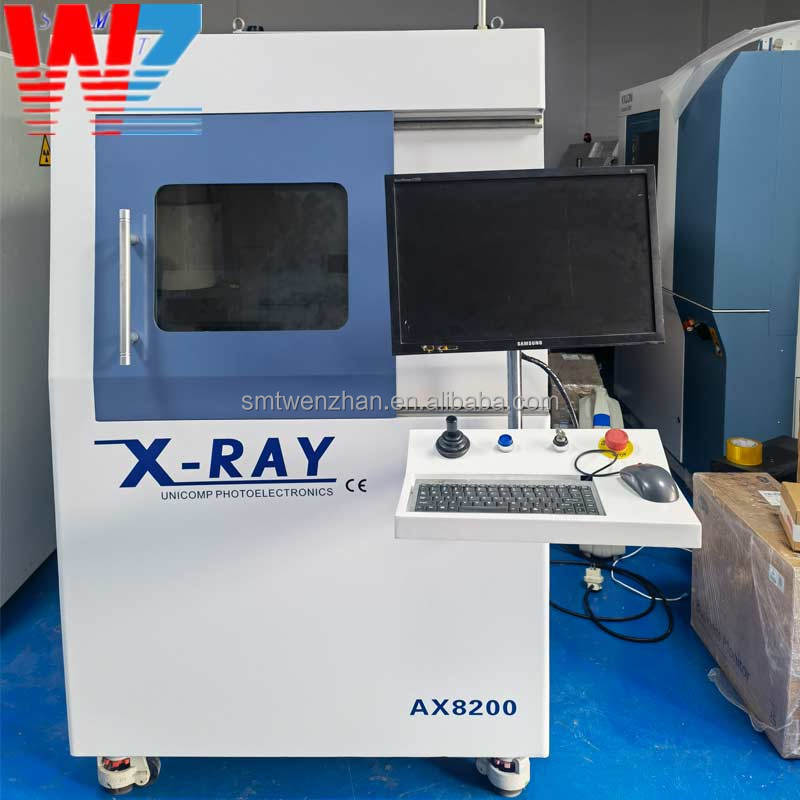

PCB X-Ray Inspection Equipment

-

model:

-

AX8200 pcb xray machine

-

Voltage:

-

220VC/50Hz

-

Function:

-

Testing

-

Dimension:

-

W1080*D1180*H1730mm

-

Power:

-

Electronic, 0.5KW

-

Condition:

-

NEW AND USED

-

Tilting Angle:

-

±60℃

-

Quality:

-

HIGH QUALITY

-

Weight:

-

1000KG

Quick Details

-

Weight (KG):

-

1000

-

Core Components:

-

pcb xray machine

-

Place of Origin:

-

China

-

Brand Name:

-

x-ray

-

Product Name:

-

PCB X-Ray Inspection Equipment

-

model:

-

AX8200 pcb xray machine

-

Voltage:

-

220VC/50Hz

-

Function:

-

Testing

-

Dimension:

-

W1080*D1180*H1730mm

-

Power:

-

Electronic, 0.5KW

-

Condition:

-

NEW AND USED

-

Tilting Angle:

-

±60℃

-

Quality:

-

HIGH QUALITY

-

Weight:

-

1000KG

Product Description

SMT 99.9% accuracy SMT PCB X-Ray Inspection Equipment X Ray Machine for LED TV Product Line

Introduction

X-Ray uses a cathode ray tube to generate high-energy electrons to collide with a metal target. During the collision process, due to the sudden deceleration of the electrons, the lost kinetic energy will be released in the form of X-Ray. For the position of the sample that cannot be detected by appearance, the change of light intensity after X-Ray penetrates materials of different densities is used to record the change of light intensity. Observe the problematic area inside the analyte while destroying the analyte.

What is the principle of X-RAY equipment detection?

The detection principle of X-RAY equipment is basically X-ray projection microscope. Under the action of high voltage, the X-ray emission tube generates X-rays through the test sample (such as PCB board, SMT, etc.), and then according to the density and atomic weight of the sample material itself, and the X-rays will also have different absorption. amount to produce an image on the image receiver. The density of the measured workpiece determines the intensity of the X-ray, and the higher the density, the darker the shadow. The closer the X-ray tube is, the larger the shadow, and vice versa, the smaller the shadow, which is the principle of geometric magnification. Of course, not only the density of the workpiece has an influence on the intensity of X-rays, but also the intensity of X-rays can be adjusted through the voltage and current of the power supply on the console. The operator can freely adjust the imaging situation according to the imaging situation, such as the display size of the image, the brightness and contrast of the image, etc., and can also freely adjust and detect the part of the workpiece through the automatic navigation function.

Features:

The device is cost-effective and supports flexible selection of enhancers and high-definition FPD

The system has 600X magnification for high-definition real-time imaging

User-friendly interface, various functions, and support for graphical results

Support optional CNC high-speed movement automatic measurement function

The standard configuration

●4/2 (optional 6-inch) image intensifier and megapixel digital camera;

●90KV/100KV-5 micron X-ray source;

●Simple mouse click operation to write detection program;

●High detection repeatability;

Rotation and tilt of plus or minus 60 degrees, allowing a unique viewing angle to detect samples;

●High-performance stage control;

●Large navigation window - easy to locate and identify defective products;

●Automatic BGA detection program detects the bubbles of each BGA, makes judgments according to customer requirements and outputs Excel reports.

Purpose:

Defect detection of internal cracks and foreign objects in metal materials and parts, plastic materials and parts, electronic components, electronic components, LED components, etc., analysis of internal displacement of BGA, circuit boards, etc.; Defects, microelectronic systems and sealing components, cables, fixtures, internal analysis of plastic parts.

Application range:

IC, BGA, PCB/PCBA, surface mount process solderability testing, etc.

Specification

|

Weight (KG)

|

1000

|

|

Showroom Location

|

United States

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

other

|

|

Place of Origin

|

China

|

|

Brand Name

|

x-ray

|

|

Warranty

|

1 Year

|

|

Product Name

|

PCB X-Ray Inspection Equipment

|

|

model

|

AX8200

|

|

Voltage

|

220VC/50Hz

|

|

Function

|

Testing

|

|

Dimension

|

L1080*W1180*H1730mm

|

|

Power

|

Electronic, 0.5KW

|

|

Condition

|

NEW AND USED

|

|

Tilting Angle

|

±60℃

|

|

BIG SIZE

|

435MM*385MM

|

|

Weight

|

1050KG

|

Packing & Delivery

1.wooden case

2.As your order

Exhibition

Hot Searches