PS profile can replace the traditional wood picture frames, mirror frame lines, decorative lines, more beautiful, wear-resistant, corrosion-resistant and other characteristics. Widely used in picture frames, photo frames, hotel and home interior decoration lines. The appearance has the real sense of wood grain texture, the surface does not need paint, and has the advantages of moisture-proof, flame retardant, easy to clean. Suitable for hotels, restaurants, shopping malls, offices, hotels and other public places and home interior decoration.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CGFE

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Size

-

Power (kW):

-

55

-

Weight:

-

3000 KG

-

Name:

-

Single Screw Extruder

-

Extruder:

-

SJ120/28

-

Screw:

-

38CrMoAIA

-

Motor:

-

Siemens Beide

-

Raw material:

-

PS

-

Inverter:

-

ABB Brand

-

Processing Type:

-

Extrusion Process

-

Capacity:

-

50-100kg/h

-

Usage:

-

Profile

-

Application Field:

-

Building Decoration

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

70 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CGFE

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Size

-

Power (kW):

-

55

-

Weight:

-

3000 KG

-

Name:

-

Single Screw Extruder

-

Extruder:

-

SJ120/28

-

Screw:

-

38CrMoAIA

-

Motor:

-

Siemens Beide

-

Raw material:

-

PS

-

Inverter:

-

ABB Brand

-

Processing Type:

-

Extrusion Process

-

Capacity:

-

50-100kg/h

-

Usage:

-

Profile

-

Application Field:

-

Building Decoration

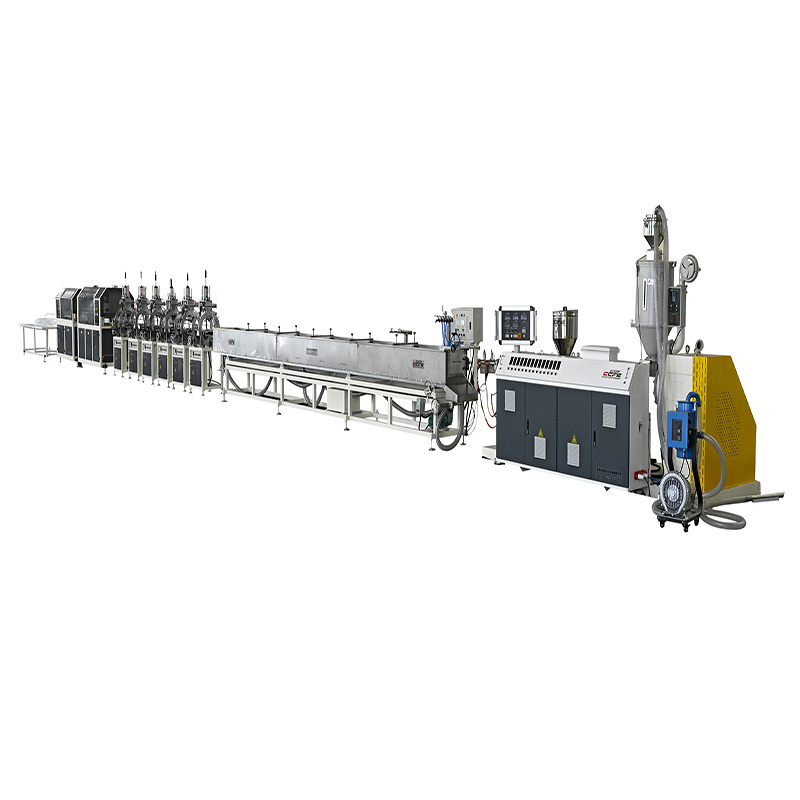

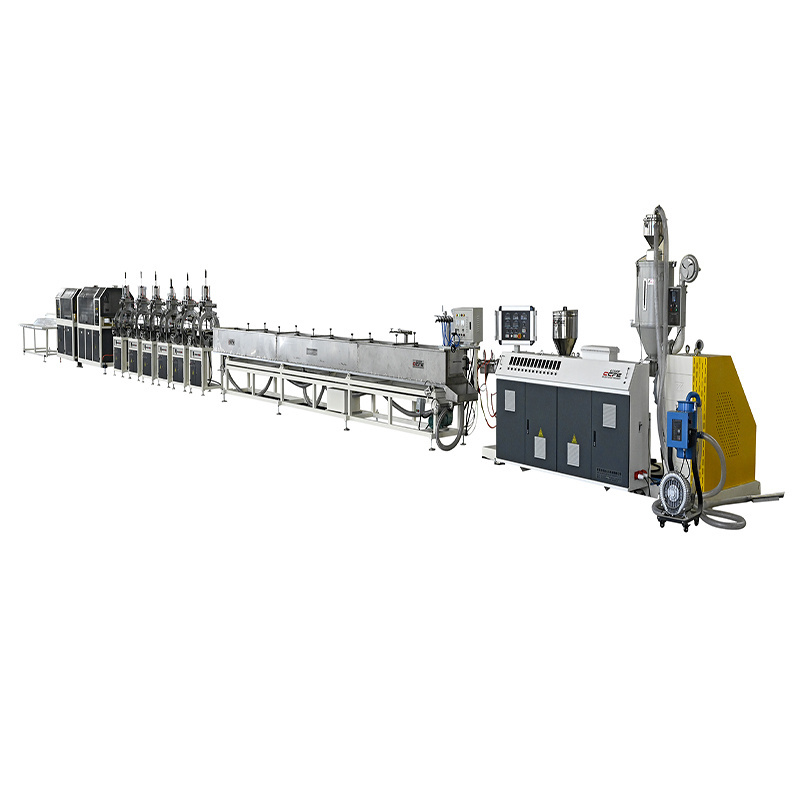

Overview

PS Foam Profile

Products Description

Process Flow

Granule

Mixing → Vacuum loading→ Drying hopper

→

Single Screw Extruder → Mould → Water cooling Tank

→

Haul-off → Cutter → Final Product Inspecting &Packing

Details Images

|

Model

|

SJ75/28

|

SJ90/28

|

SJ100/28

|

SJ120/28

|

|

Screw Dia(mm)

|

75

|

65

|

75

|

90

|

|

L/D

|

28:1

|

28:1

|

28:1

|

28:1

|

|

Main Motor

|

30

|

45

|

45

|

75

|

|

Max.Products size(mm)

|

100*20

|

120*30

|

230*30

|

300*30

|

|

Output(Kg/h)

|

20-40

|

20-50

|

20-60

|

40-90

|

Die head&Mould

--Mould with good quality

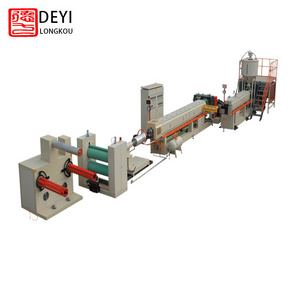

Water Cooling Tank

--PS cooling water tank, is used to pass water to cool the profile, to the product to play the role of shaping

--304 stainless steel with painted outer surface

--External water supply, with large capacity, water immersion cooling.

--Yulong vacuum pump, vacuum shaping

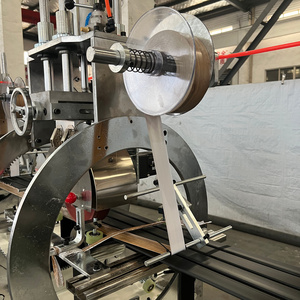

Water Cooling Tank

--Stamping machine, by heating the stamping rollers. It can be customised with different thickness of stamping rollers according to different products.

--Also can be equipped with embossing, embossing rollers to make different concave and convex surface shape patterns.

Hot Stamping Device

Haul-off machines

--Upper and lower caterpillar is driven separately and speed control by frequency inverter;

--Belt track,better for the products;

--Install plate is adopts aluminum material;

--Compacting driving by pneumatic;

Haul-off machines

--Lifting saw cutter ;

--Synchronous driving by air cylinder or servo motor control.

Why Choose Us

Technology cooperation

Our Company

Golden Far East Machinery Co., ltd. is a high-tech enterprise which is specialized in research, manufacture and marketing plastic extrusion lines. It is located in the beautiful port city of Zhangjiagang with convenient traffic; it's about 150 km away from Shanghai.

Our products include single screw extruder, twin screw extruder, PVC/HDPE/PP-R pipe extrusion line, PVC profile extrusion line,

WPC profile extruding line, high speed mixer and plastic sheet production lines with the relative plastic auxiliary machine, etc.

Our products have been exported to Egypt, Uzbekistan, Brazil, Turkey, Russia, UAE, Thailand, Italy, etc.

WPC profile extruding line, high speed mixer and plastic sheet production lines with the relative plastic auxiliary machine, etc.

Our products have been exported to Egypt, Uzbekistan, Brazil, Turkey, Russia, UAE, Thailand, Italy, etc.

Exhibition

2023 ChinaPlast

2023 IranPlast

2024 Bangladesh IPF

Contact us

FAQ

1.Your company is a trading company or a direct factory?

We are a direct factory located in Zhangjiagang City. Very close to Shanghai and Wuxi (airport and train provided). If you

arrive in Shanghai or Wuxi, we can pick you up to visit our factory.

2.If we buy your machine, what is your guarantee or guarantee of quality?

We provide you with high-quality machines with 1-year warranty and lifetime technical support.

3.How to ensure the safety of your funds and deliver on time?

(1) Through Alibaba's letter guarantee service, it will ensure on-time delivery and the quality of the equipment to be purchased.

(2) Through the letter of credit, you can easily lock the delivery time.

(3) After visiting the factory, you can ensure the authenticity of our bank account.

4. How to ensure the quality of machine?

(1) In order to ensure the accuracy of each part, we are equipped with various professional processing equipment, and we have

accumulated professional processing methods in the past few years.

(2) Each component before assembly needs to be strictly controlled by inspectors.

(3) After all equipment is completed, we will connect all machines and run the entire production line in our company before

shipping to ensure the stable operation.

We are a direct factory located in Zhangjiagang City. Very close to Shanghai and Wuxi (airport and train provided). If you

arrive in Shanghai or Wuxi, we can pick you up to visit our factory.

2.If we buy your machine, what is your guarantee or guarantee of quality?

We provide you with high-quality machines with 1-year warranty and lifetime technical support.

3.How to ensure the safety of your funds and deliver on time?

(1) Through Alibaba's letter guarantee service, it will ensure on-time delivery and the quality of the equipment to be purchased.

(2) Through the letter of credit, you can easily lock the delivery time.

(3) After visiting the factory, you can ensure the authenticity of our bank account.

4. How to ensure the quality of machine?

(1) In order to ensure the accuracy of each part, we are equipped with various professional processing equipment, and we have

accumulated professional processing methods in the past few years.

(2) Each component before assembly needs to be strictly controlled by inspectors.

(3) After all equipment is completed, we will connect all machines and run the entire production line in our company before

shipping to ensure the stable operation.

Hot Searches