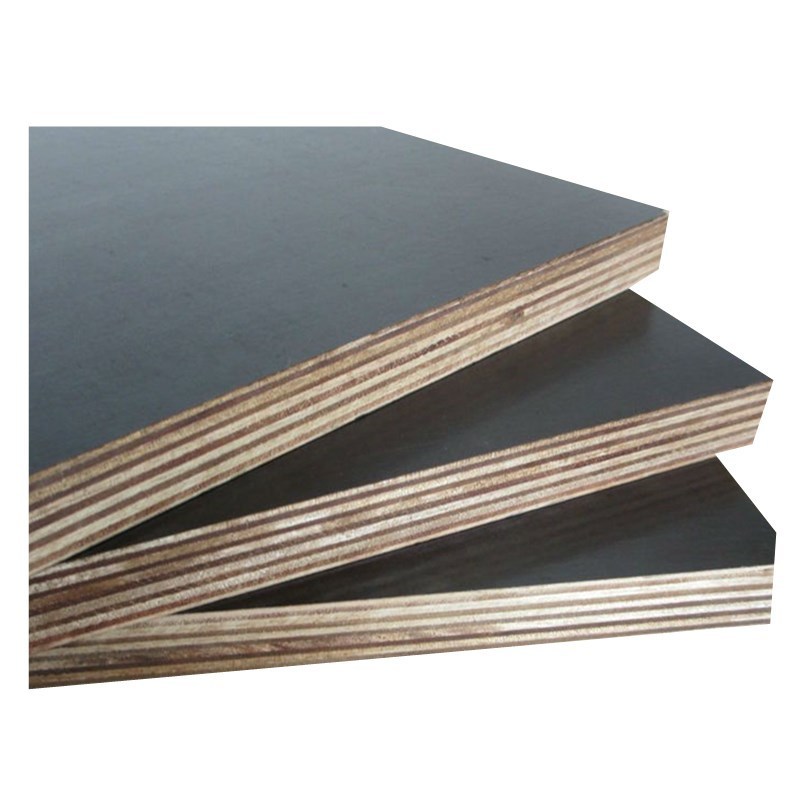

Core Venners

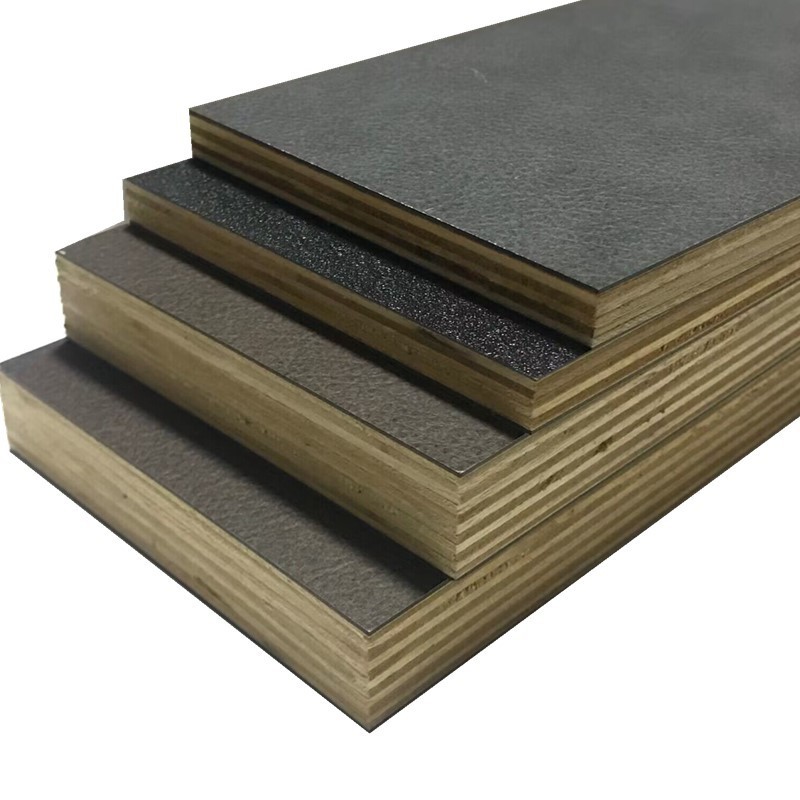

Use fresh full core and assemble different layers of veneers in different direction to guarantee the high strength and smooth flat

surface of the plywood.

- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Waying

-

Model Number:

-

Film faced plywood

-

Product name:

-

Good quality waterproof concrete formwork film faced plywood

-

Thickness:

-

9-25mm

-

Size:

-

1220*2440, 1250*2500, 610*2440, 915*1830mm

-

Thickness tolerance:

-

+/- 0.5mm

-

Glue:

-

WBP - Melamine Glue

-

Hot pressed time:

-

2 times

-

Moisture:

-

6%-12%

-

Certification:

-

ISO

-

Advantage:

-

Good strength, factory direct, quality and reputation protection

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Apartment

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Waying

-

Model Number:

-

Film faced plywood

-

Product name:

-

Good quality waterproof concrete formwork film faced plywood

-

Thickness:

-

9-25mm

-

Size:

-

1220*2440, 1250*2500, 610*2440, 915*1830mm

-

Thickness tolerance:

-

+/- 0.5mm

-

Glue:

-

WBP - Melamine Glue

-

Hot pressed time:

-

2 times

-

Moisture:

-

6%-12%

-

Certification:

-

ISO

-

Advantage:

-

Good strength, factory direct, quality and reputation protection

12mm 18mm Marine Plywood Phenolic Board Film Faced Plywood for Philippines Market

1220*2440*18mm full birch core marine film faced plywood for construction

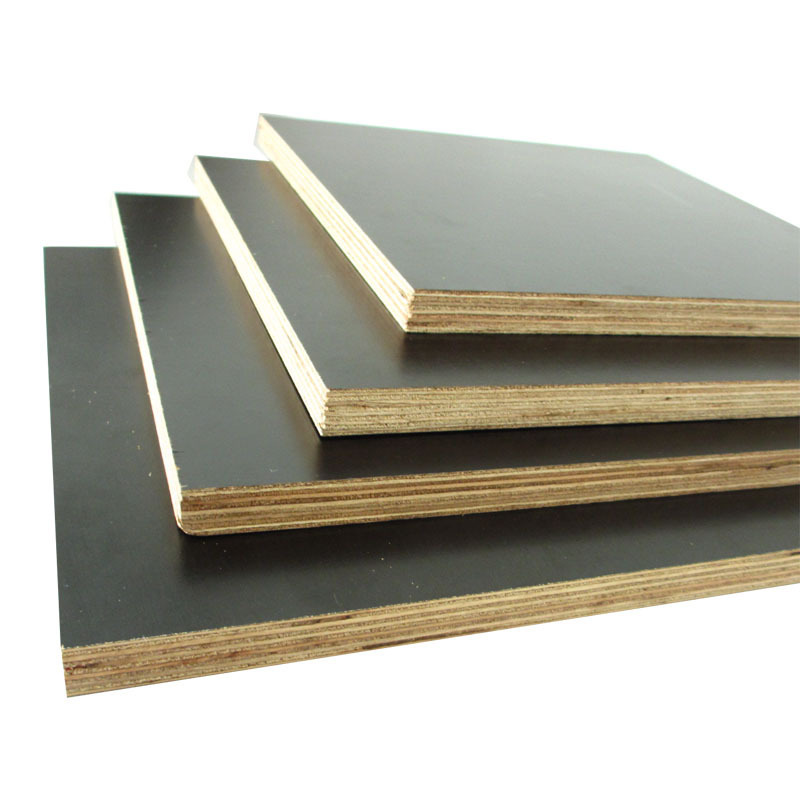

What is phenolic film faced plywood?

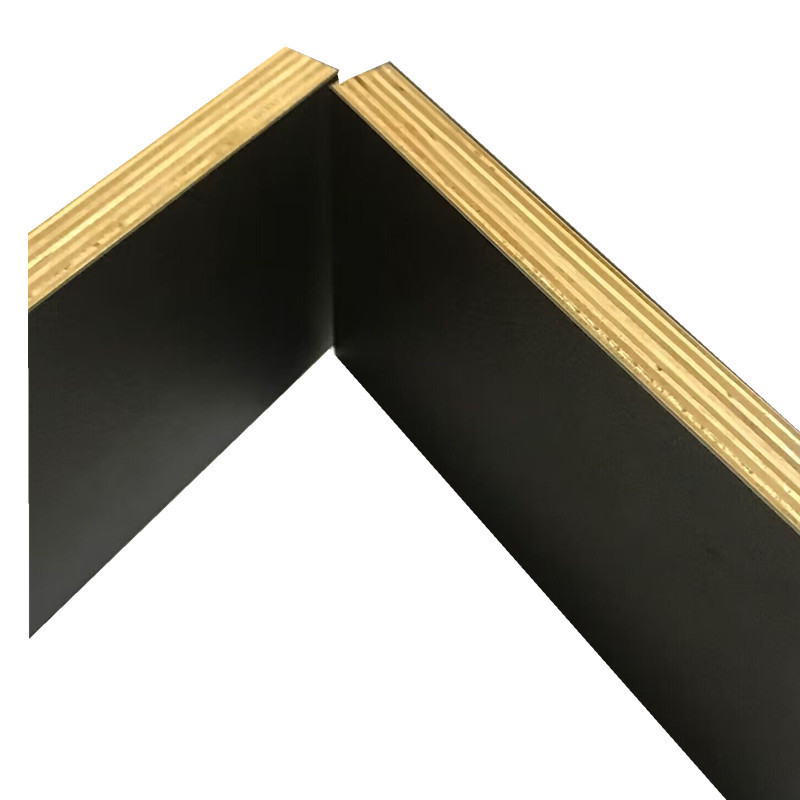

It is made by pressing paper saturated with phenolic resin (called phenolic film) on a surface of exterior plywood. The surface coated with the film protects the sheets from moisture and improves their resistance to abrasion. Edges of shuttering plywood are protected with waterproof acrylic paint. it also been called phenolic board, phenolic plywood, marine plywood, construction plywood, film faced plywood, brown film faced plywood for construction, marine construction plywood, black film faced plywood, marineplex plywood for concreforwork. its been widly used for construction usage.

What is phenolic film faced plywood?

It is made by pressing paper saturated with phenolic resin (called phenolic film) on a surface of exterior plywood. The surface coated with the film protects the sheets from moisture and improves their resistance to abrasion. Edges of shuttering plywood are protected with waterproof acrylic paint. it also been called phenolic board, phenolic plywood, marine plywood, construction plywood, film faced plywood, brown film faced plywood for construction, marine construction plywood, black film faced plywood, marineplex plywood for concreforwork. its been widly used for construction usage.

|

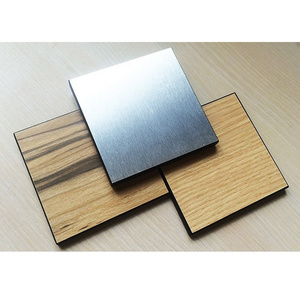

F&B Film:

|

Film Faced Plywood

|

|

|

|

|||

|

Grade:

|

A./B

|

|

|

|

|||

|

Core:

|

Eucalyptus,Okoume,birch, ,combi, hardwood,etc.

|

|

|

|

|||

|

Glue:

|

WBP

|

|

|

|

|||

|

Thickness:

|

2mm-30mm

|

|

|

|

|||

|

Specifications:

|

Normal size: 1220mmx2440mm,1250mmx2500mm,1530x3150mm

|

|

|

|

|||

|

Package:

|

Inner Packing: Pallet is wrapped with a 0.20mm plastic paper

Outer Packing: Pallet is covered with plywood or carton and then PVC/steel tapes for strength |

|

|

|

|||

|

Loading:

|

20'GP: 8pallets/22.5cbm

40'GP: 16pallets/42cbm 40'HQ: 18pallets/53cbm |

|

|

|

|||

|

Certificates:

|

LR, ISO9001, ISO14001

|

|

|

|

|||

|

Price terms:

|

FOB, CNF, CIF

|

|

|

|

|||

|

Delivery time:

|

Within 20 days after receipt of the original L/C or the 30% advanced payment

|

|

|

|

|||

|

More Details:

|

Density: 400-880kgs/m3

Moisture Content: below 14% Thickness Tolearance: +/-0.3mm to +/-0.5mm Modulus of Elasticity: >=5000Mpa Static Bending Strength: >=30Mpa Surface Bonding Strength: >=1.60Mpa Internal Bonding Strength: >=0.90Mpa Screw Holding Ability: Face >=1900N ; Edge>=1200N |

|

|

|

|||

About Production

High-quality

original material

Raw materials in Guangxi are the largest artificial panel production area in China.

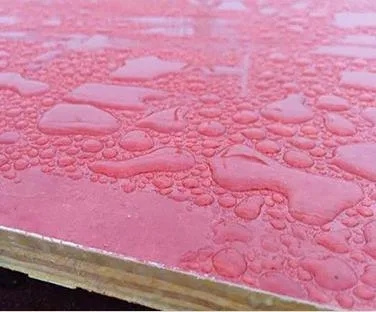

Good Waterproof Performance

To use waterproof and wear resistant phenolic glue which make it high temperature resistant, low temperature resistant, acid and alkali resistant and stable performance.

Double-sided waterproof membrane, reusable, also very durable in harsh conditions.

Fall resistance, low carbon environmental protection, pressure resistance, wear resistance, low carbon environmental protection,

humidity resistance, bending resistance

humidity resistance, bending resistance

Easy to use: the surface of the pouring object is smooth and beautiful, minus the secondary plastering process of the wall, which can directly decorate the surface and shorten the construction period.

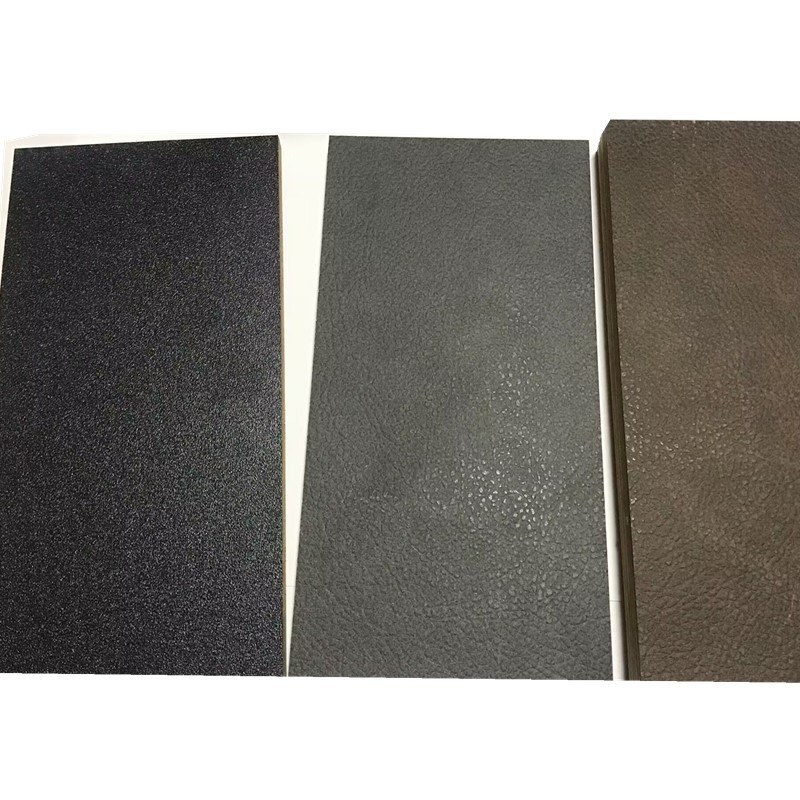

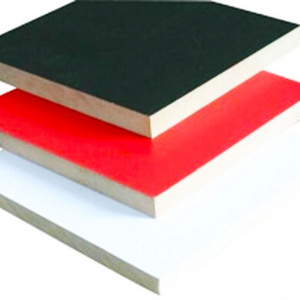

Three colors: red, black and brown,

can customize the logo you want

productive process

Certificate

CONTACT US

Doris Deng

Mail: nnwymy(at)nnwymy.com

Mob&Whatsapp&Wechat: +86 18877103212

Tel / Fax:+86 771-2022657

Doris Deng

Mail: nnwymy(at)nnwymy.com

Mob&Whatsapp&Wechat: +86 18877103212

Tel / Fax:+86 771-2022657

Hot Searches