- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

300-9500KG

-

Size:

-

2100*800*1400 (mm)

-

Power:

-

different as each model

-

Weight (KG):

-

500 kg

-

DS Treating Capacity:

-

5~640 kg Ds/h

-

Certification:

-

CE ISO

-

Use:

-

Sludge thickening and dewatering

-

Outlet cake moisture content:

-

75%-85%

-

Motor:

-

Chinese Famous Brand/SEW/Nord//Customize

-

Electrical component:

-

Schneider/Customize

-

Protection Level:

-

IP55 F

-

Inlet SS Concentration:

-

1%-5%

-

Weight/Running weight:

-

250kg/395kg~7000kg/12960kg

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JSPONIS

-

Material:

-

Plywood wooden case, SS304

-

Weight:

-

300-9500KG

-

Size:

-

2100*800*1400 (mm)

-

Power:

-

different as each model

-

Weight (KG):

-

500 kg

-

DS Treating Capacity:

-

5~640 kg Ds/h

-

Certification:

-

CE ISO

-

Use:

-

Sludge thickening and dewatering

-

Outlet cake moisture content:

-

75%-85%

-

Motor:

-

Chinese Famous Brand/SEW/Nord//Customize

-

Electrical component:

-

Schneider/Customize

-

Protection Level:

-

IP55 F

-

Inlet SS Concentration:

-

1%-5%

-

Weight/Running weight:

-

250kg/395kg~7000kg/12960kg

Product Details

specification

|

Material

|

SS304

|

|

Core components

|

Gearbox、Motor、PLC

|

|

country of origin

|

Jiangsu, China

|

|

brand

|

JSPONIS

|

|

Product size

|

2100*800*1400 (mm)

|

|

Rated power of motor (KW):

|

different as each model

|

|

Warranty period

|

1 year

|

|

USE

|

Sludge thickening and dewatering

|

|

Motor

|

Chinese Famous Brand/SEW/Nord//Customize

|

|

Electrical component

|

Schneider/Customize

|

|

Protection Level

|

IP55 F

|

|

Inlet SS Concentration

|

1%-5%

|

Recommend Products

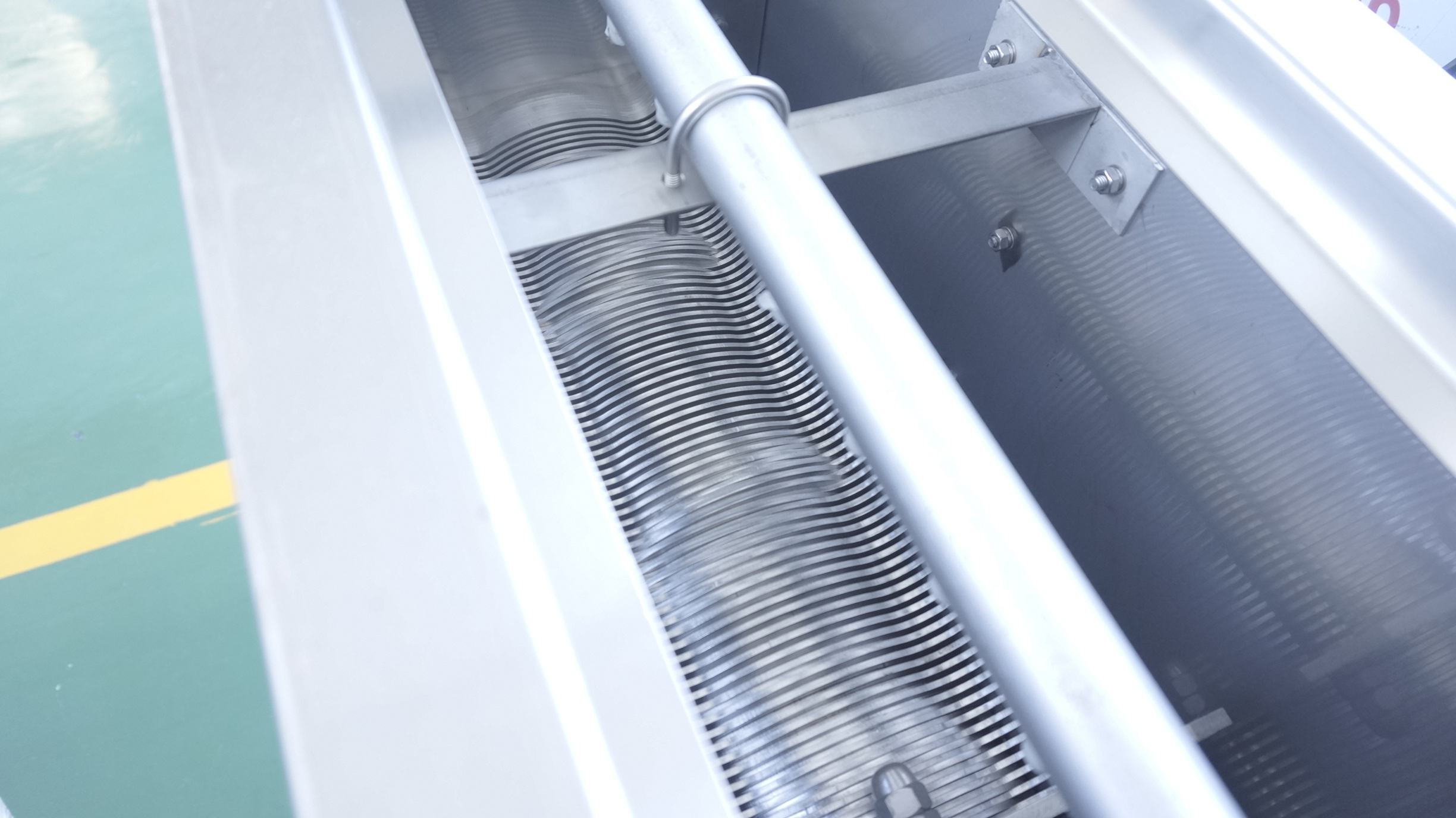

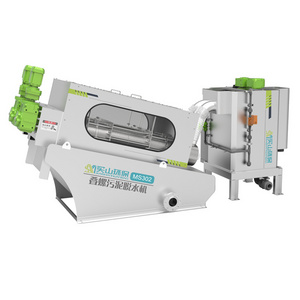

Based on the Japanese technology, JSPONIS volute screw sludge dewatering machine is a new type of environmental equipment with the features of no belt, clog-free, anti-wear and low-energy consumption. The core part of the machine is composed of screw shaft, fixed rings and moving rings. With the help of gravity, water fall from the gaps of the rings, so the sludge is separated from the water.

The stacked screw type sludge dewatering machine can be used for municipal sewage, petroleum refining, food processing, brewing and tanning, printing, dyeing and papermaking, coal processing and beneficiation, biochemical pharmacy, steel pickling, chemical sugar making, etc.

The stacked screw type sludge dewatering machine can be used for municipal sewage, petroleum refining, food processing, brewing and tanning, printing, dyeing and papermaking, coal processing and beneficiation, biochemical pharmacy, steel pickling, chemical sugar making, etc.

Advantages of the product

1、No filtration cloth, no fouling, abrasion resistance, low energy consumption. Unit electricity is 0.1kwh/kgDS, unit water

consumption is 0.03th.

2、Clean and environmental, no odor, no noise, no high-pressure washing, no secondary pollution.

3、Operate continuously and efficiently without human intervention for 24 hours.

4、Directly dehydrate without the need for a concentration tank.

5、Easy to degrade low concentration sludge and special oily sludge.

6、No abrasion, Small footprint.

consumption is 0.03th.

2、Clean and environmental, no odor, no noise, no high-pressure washing, no secondary pollution.

3、Operate continuously and efficiently without human intervention for 24 hours.

4、Directly dehydrate without the need for a concentration tank.

5、Easy to degrade low concentration sludge and special oily sludge.

6、No abrasion, Small footprint.

Hot Searches