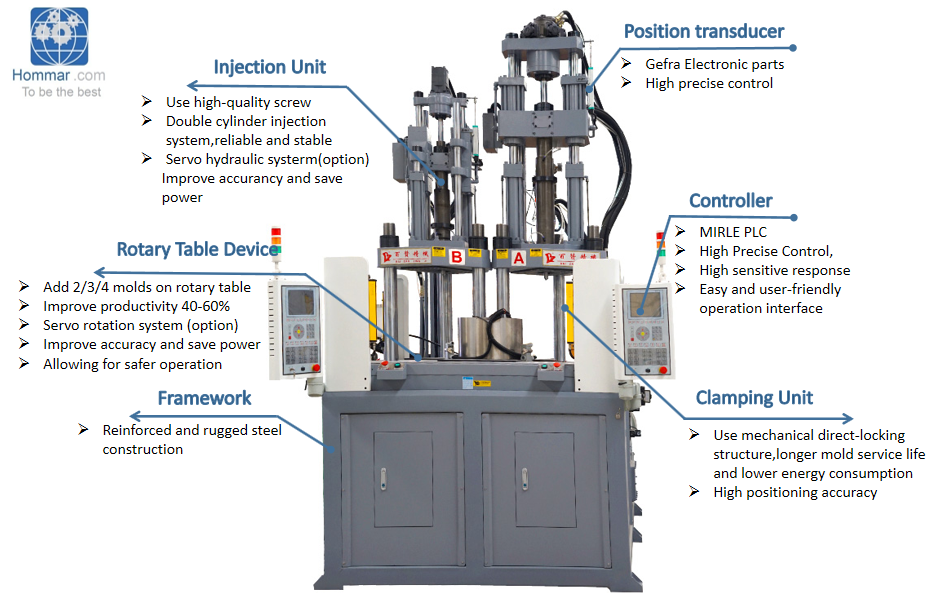

Hommar is a professional manufacturer of vertical injection molding

machine since 1998.

Always focus on upper-class quality machines .

Developing at least 15 new machines every year.

CE certification