DISK automatic spray booth

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V/110V

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

2000

-

Conveyor speed:

-

0-6m/min adjustable

-

Spraying Mode:

-

Automatic

-

After-sales Service:

-

Video technical support, Engineers available to service overseas

Quick Details

-

Machine Type:

-

DISK electrostatic coating machine, Spray Booths, Painting Equipment, Pre-treatment Equipment, Conveying Equipment, Coating Equipment, Other

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Ailin

-

Voltage:

-

380V/220V/110V

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

2000

-

Conveyor speed:

-

0-6m/min adjustable

-

Spraying Mode:

-

Automatic

-

After-sales Service:

-

Video technical support, Engineers available to service overseas

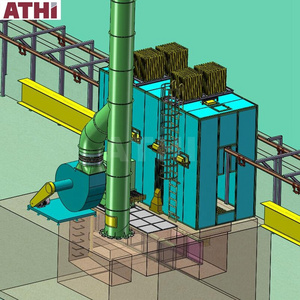

Ailin I

ntelligent

specializes in optimizing various types of project in the business of industrial surface treatment lines. We have a great deal of experience in coating line system for nearly 13+ years, and provide technical support as well as installation guide to customers. The pictures above show the cases of practical application in workshops FYI.

PRODUCT DESCRIPTION

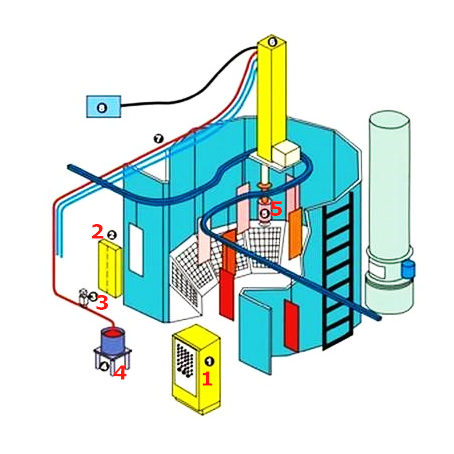

Liquid Paint DISK Spray Booth Automatic Electrostatic Spraying Painting Line

Automatic spray paint line includes the automatic dust removing, automatic spraying paint, automatic drying and automatic cooling.

1. High precision, the running accuracy is within 0.2mm, the spraying accuracy is within 0.2-1mm.

2.

Spray evenly and f

lexible spraying size can save 20% paint.

3. Save labor and cost,

high efficiency ,can reach continuous work for 24 hours, the output is 3-5 times than the labor.

4. Fully visual touch screen control, operate easily, can save and read the data quickly.

5. Spraying degugging is simple within ten mins,The program is easy to operate.

Excellent Features:

Process Flow of Spray Painting

|

Equipment

|

Application

|

|

Pretreatment System:

|

Better spraying effect on workpiece.

|

|

Paint Spray Booth:

|

Automatic spraying on the surface of the workpiece.

|

|

Transport System:

|

Overhead conveyor runs automatically and smoothly.

|

|

Curing Oven:

|

Make the paint firmly attached to the workpiece.

|

|

Heating System:

|

The fuel can choose diesel oil, gas, electric, LPG etc.

|

Upload---Pretreatment---Electrostatic dedusting---Bottom painting---Surface drying---Finishing painting---Curing---Cooling---Unloading---Vacuum metallization

COMPONENT DETAILS

Electrostatic Generator

Pneumatic Atomizer

Control Cabinet

Omega Reciprocator

Gear Pump

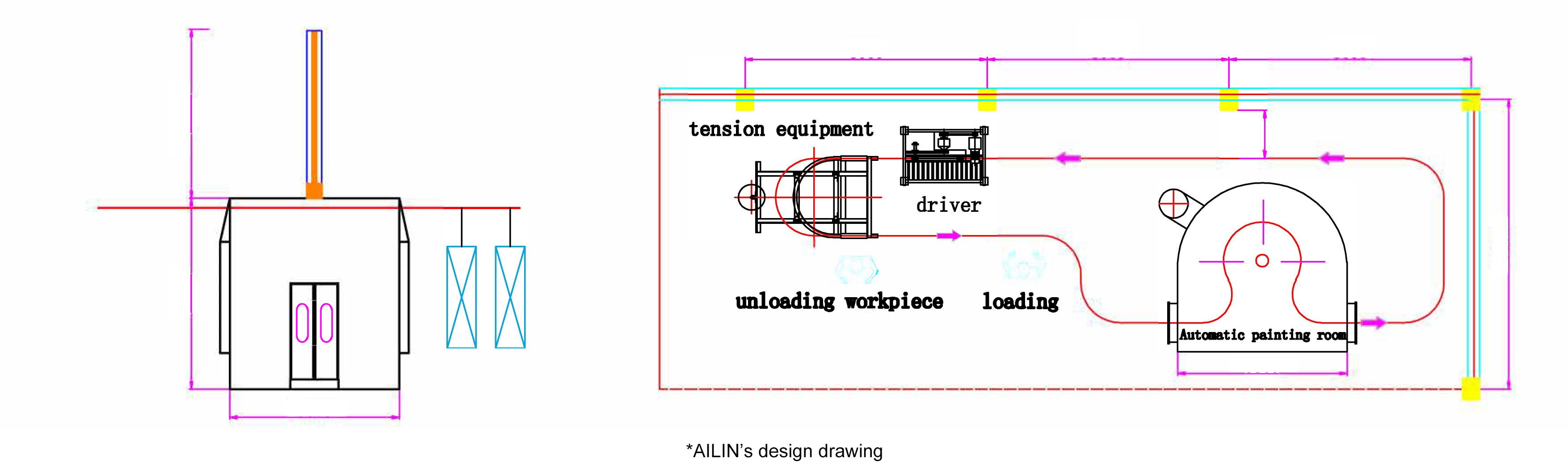

CUSTOMIZATION SOLUTION

How to get an optimal solution for the automatic spraying paint line?

Ailin coating has a professional and efficient working team. Our professional senior engineer will find the best solution for you.

You'd better offer the specifications of your workpiece and related information to us:

1.

The production process (if you're new on coating, we will give you specialized suggestions of the whole work)

2. The size of your workpieces (including the max length, width, height and weight)

3. The capacity/daliy output (how many pcs in 8 hours)

4. The available size of your factory (including the length, width and height)

5. The heating power (electricity, gas or diesel oil )

6. Automatic painting or manual painting pre-treatment process or not, if you do, automatic pretreatment, dipping pre-treatment or sand blasting.

7. How many colors do you need to change every day.

8. The local electricity conditions (_v/_phase/_hz)

Our coating system's design and production are all according to customer's requirement (capacity, size of workpiece, size of work space).

2. The size of your workpieces (including the max length, width, height and weight)

3. The capacity/daliy output (how many pcs in 8 hours)

4. The available size of your factory (including the length, width and height)

5. The heating power (electricity, gas or diesel oil )

6. Automatic painting or manual painting pre-treatment process or not, if you do, automatic pretreatment, dipping pre-treatment or sand blasting.

7. How many colors do you need to change every day.

8. The local electricity conditions (_v/_phase/_hz)

Our coating system's design and production are all according to customer's requirement (capacity, size of workpiece, size of work space).

PRODUCT CATEGOTIES

ABOUT US

FAQ

Hot Searches