- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Singapore

-

Brand Name:

-

AD RACKING

-

Model Number:

-

ADRACKING-20240528-08

-

Depth:

-

850-1050 mm Or Customized

-

Weight Capacity:

-

5000kg (each shelf )

-

Width:

-

1800/2700/3600mm Or Customized

-

Height:

-

Max 12000mm Or Customized

-

Aisle Selection:

-

Single Row, back-to-back Rows, and multiple Rows

-

Construction Type:

-

Bolted Frame

-

Beam Type:

-

Step Beam/Box Beam

-

Upright:

-

80*60; 90*60; 90*70; 90*75; 100*67; 100*70; 100*75; 120*95mm

-

Beam:

-

Height: 80~160mm; Width: 50mm; Thickness: 2.0-2.5mm

-

Shelf Height Adjustment:

-

75/50mm

-

OEM&ODM:

-

Yes

-

Color:

-

Blue, Orange or Customized: All RAL Color

-

Surface Finish:

-

Powder Coated/ Galvanized

-

Supply Ability:

-

50000 Set/Sets per Month warehouse racking

Quick Details

-

Type:

-

Selective Pallet Rack

-

Material:

-

Steel

-

Feature:

-

Corrosion Protection

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Singapore

-

Brand Name:

-

AD RACKING

-

Model Number:

-

ADRACKING-20240528-08

-

Depth:

-

850-1050 mm Or Customized

-

Weight Capacity:

-

5000kg (each shelf )

-

Width:

-

1800/2700/3600mm Or Customized

-

Height:

-

Max 12000mm Or Customized

-

Aisle Selection:

-

Single Row, back-to-back Rows, and multiple Rows

-

Construction Type:

-

Bolted Frame

-

Beam Type:

-

Step Beam/Box Beam

-

Upright:

-

80*60; 90*60; 90*70; 90*75; 100*67; 100*70; 100*75; 120*95mm

-

Beam:

-

Height: 80~160mm; Width: 50mm; Thickness: 2.0-2.5mm

-

Shelf Height Adjustment:

-

75/50mm

-

OEM&ODM:

-

Yes

-

Color:

-

Blue, Orange or Customized: All RAL Color

-

Surface Finish:

-

Powder Coated/ Galvanized

-

Supply Ability:

-

50000 Set/Sets per Month warehouse racking

Details Images

Products Description

|

Products Support

|

|

|

Free Con

sulta

tion

|

Yes, Any Questions You Can Consult With Free.

|

|

Support For Custom

|

Yes

|

|

Free Design

|

Yes, CAD/PDF/3D Drawing

|

|

Free Sample

|

Available (Delivery Cost By Buyer)

|

|

3D Sample

|

Yes, 1:1 3D Sample, Save Your Time And Cost of Trial and Error

|

|

Pre-installation

|

Yes

|

|

Capacity Test

|

Yes, If Needed.

|

|

OEM&ODM

|

Available

|

|

Lead Time

|

15-20 Days For Regular Pallet Racking, One Container

|

|

Installation Service

|

Yes, Submit the Installation Drawing Or Video, and send the Engineer To Your Site If Needed.

|

|

Maintenance Service

|

Yes, We Submit a Free Maintenance Guide.

|

|

Repair Service

|

Yes, We Submit Repair Services.

|

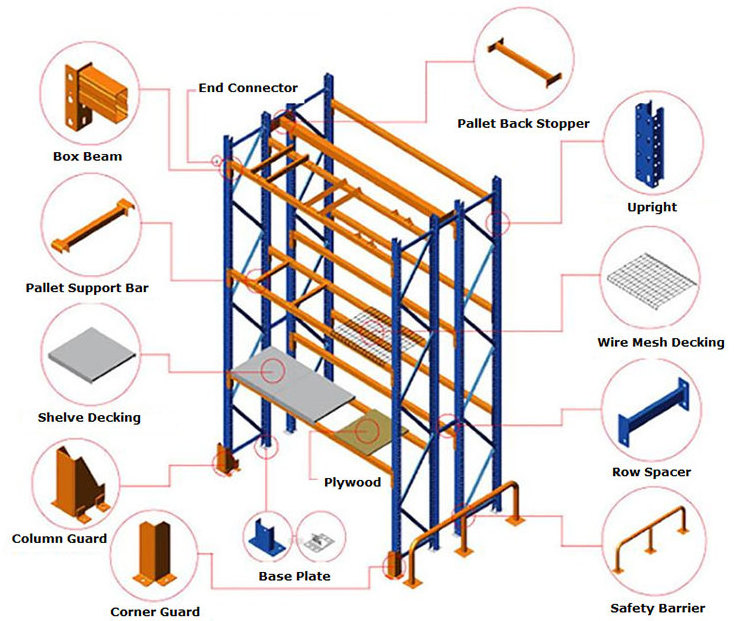

The following introduces you to different pallet racking components:

Upright

:

Upright plays an important role in connecting each beam of pallet racking and broadening the entire storage space.

Frame:

the main role of the frame is to connect the beam and guarantee the whole pallet racking more stability.

Beam

: beams ca

n be u

sed to get strong support for your pallet racking.

Base Plate

: fix the bottom of pallet racking.

Upright Protector

:

fix the upright columns to avoid the frame being unstable, and protect the racks.

Shim

: make the bottom of the pallet racking more flatter

Connecting Bolt

: It is responsible for connecting the beams and frames

Customized Services

AD RACKING supports customization, such as drawing、color、package and size etc.

Why Choose Us

1.Strictly Racking

Qualit

y Inspection

AD Racking Systems has a professional quality inspection team consisting of 15 people, we check the pallet racking quality for every producing step, it can guarantee the quality of your racking during processing.

2.Advan

ced Produ

ction Equipment

A variety of complete equipment to make sure the delivery time and quality are within our control range.

3.The Best Racking Quality of Powder Coating

AD racking via two times powerful pickling technology to make oxidize very well and produce a layer of oxidation film on the steel surface, which can make the resin powder adsorb better on the steel,

No Other Supplier Match

!

Greatly increased your racking life.

Our Safety Assurance

The stability of our shelves and the safety of personnel are always our top priorities.

High-quality materials and Stringent Inspection Standards form the foundation of our shelf stability.

High-Quality Steel:

We use premium Q235 cold-rolled steel from top steel manufacturer.

Q235 steel boasts excellent mechanical properties:

Yield Strength: Approximately 235 MPa

Tensile Strength: Ranging from 370-500 MPa

Elongation: Approximately 26% (at a 200mm gauge length)

In addition, we have specifically equipped safety accessories to ensure security.

Footplates : Footplates are fixed to the ground using expansion screws. Depending on the load-bearing capacity, we provide both Type II Footplates and enclosed Footplates.

Guardrail : Mainly U-shaped (240mm long, 500mm high, 2.0mm thick), not in contact with the shelves, anchored to the ground primarily to prevent forklifts from knocking down the shelves.

Rear Crossbeam : Rear crossbeams are installed at the back of the shelves to prevent goods from falling off the shelves and provide additional safety protection for operators.

Safety Bolt : 7-shaped, inserted into the holes of the uprights to maintain the stability of the beams.

Back Mesh : Installed on the sides of the shelves to prevent small items from scattering.

Pallet Stops : These devices prevent goods from sliding or rolling on the shelves, ensuring that the goods are securely placed in the proper position.

Goods Dividers : Used to separate goods to prevent them from tilting or collapsing when stacked.

Mesh Decking : Different-sized items can also be placed on the shelves, eliminating fire hazards associated with wooden boards.

Pallet Supports : Increase beam support and prevent items from falling, available in two types: straight and diagonal designs.

Diagonal Braces : Support structures between shelf uprights that increase the overall stability of the shelves, reducing lateral deformation and shaking.

Cross Braces : These connectors can be installed between the horizontal beams of the shelves to increase overall rigidity.

Signage and Warnings : Safety signs, warning signs, and instructions help operators use the shelves correctly and remind them of safety precautions.

Row spacer : Maintains stability between mainframes and sub-frames.

Shims : Provide shock absorption, reduce noise, adjust shelf height and horizontal angles, and prevent shelf sliding.

High-quality materials and Stringent Inspection Standards form the foundation of our shelf stability.

High-Quality Steel:

We use premium Q235 cold-rolled steel from top steel manufacturer.

Q235 steel boasts excellent mechanical properties:

Yield Strength: Approximately 235 MPa

Tensile Strength: Ranging from 370-500 MPa

Elongation: Approximately 26% (at a 200mm gauge length)

In addition, we have specifically equipped safety accessories to ensure security.

Footplates : Footplates are fixed to the ground using expansion screws. Depending on the load-bearing capacity, we provide both Type II Footplates and enclosed Footplates.

Guardrail : Mainly U-shaped (240mm long, 500mm high, 2.0mm thick), not in contact with the shelves, anchored to the ground primarily to prevent forklifts from knocking down the shelves.

Rear Crossbeam : Rear crossbeams are installed at the back of the shelves to prevent goods from falling off the shelves and provide additional safety protection for operators.

Safety Bolt : 7-shaped, inserted into the holes of the uprights to maintain the stability of the beams.

Back Mesh : Installed on the sides of the shelves to prevent small items from scattering.

Pallet Stops : These devices prevent goods from sliding or rolling on the shelves, ensuring that the goods are securely placed in the proper position.

Goods Dividers : Used to separate goods to prevent them from tilting or collapsing when stacked.

Mesh Decking : Different-sized items can also be placed on the shelves, eliminating fire hazards associated with wooden boards.

Pallet Supports : Increase beam support and prevent items from falling, available in two types: straight and diagonal designs.

Diagonal Braces : Support structures between shelf uprights that increase the overall stability of the shelves, reducing lateral deformation and shaking.

Cross Braces : These connectors can be installed between the horizontal beams of the shelves to increase overall rigidity.

Signage and Warnings : Safety signs, warning signs, and instructions help operators use the shelves correctly and remind them of safety precautions.

Row spacer : Maintains stability between mainframes and sub-frames.

Shims : Provide shock absorption, reduce noise, adjust shelf height and horizontal angles, and prevent shelf sliding.

Successful Case

Hot Searches