- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

4.8*1.8*2.8m

-

Weight:

-

4500 KG

-

Printing color:

-

6

-

Max.feeding area:

-

1200*800mm

-

Max.Printing area:

-

1150*660mm

-

Printing speed:

-

200-2400pcs/h

-

Thickness of printing plate:

-

4-6mm

-

After Warranty Service 1:

-

Video technical support

-

After Warranty Service 2:

-

Online support

-

After Warranty Service 3:

-

Spare parts

-

After Warranty Service 4:

-

Field maintenance and repair service

-

Certification:

-

CE/ISO

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Zhuding

-

Voltage:

-

380/220V

-

Dimensions(L*W*H):

-

4.8*1.8*2.8m

-

Weight:

-

4500 KG

-

Printing color:

-

6

-

Max.feeding area:

-

1200*800mm

-

Max.Printing area:

-

1150*660mm

-

Printing speed:

-

200-2400pcs/h

-

Thickness of printing plate:

-

4-6mm

-

After Warranty Service 1:

-

Video technical support

-

After Warranty Service 2:

-

Online support

-

After Warranty Service 3:

-

Spare parts

-

After Warranty Service 4:

-

Field maintenance and repair service

-

Certification:

-

CE/ISO

Banner

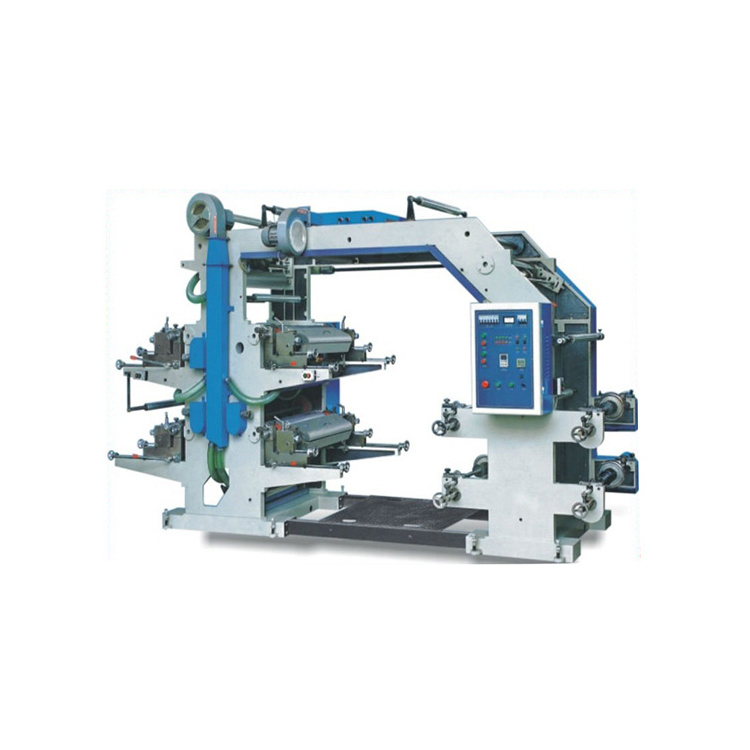

Product Description

Performance and Characteristics:

This machine is suitable for printing such packing materials as poltpropylene palstic bag, glass paper and web, etc. And it is the ideal printing equipment for producing paper packing bag for food, supermarket handbag, and clothes bag etc.

1. easy operation, flexible starting, accurate color register.

2. the number counter can set printing quality as required. Stop the machine automatically at the set quantity or when the

material is cut off.

3. lift and lower the printing plate cylinder manually, it will automatically stir the printing ink after lifting.

4. the printing ink is stransmitted by the cobweb barrel with even ink color.

5. reliable drying system coodinated with high-speed rotation willautomatically break the circuit when the machine stops

6. 180 continuous abd adjustable longitudinal register device

7. the imported frequency conversion control of motor for speed adopts to different printing speeds

8. there are "run"&“stop" buttons on the plate roller base and material drawing-in rack so as to make in easy for seperating the machine when the plate is installed.

1. easy operation, flexible starting, accurate color register.

2. the number counter can set printing quality as required. Stop the machine automatically at the set quantity or when the

material is cut off.

3. lift and lower the printing plate cylinder manually, it will automatically stir the printing ink after lifting.

4. the printing ink is stransmitted by the cobweb barrel with even ink color.

5. reliable drying system coodinated with high-speed rotation willautomatically break the circuit when the machine stops

6. 180 continuous abd adjustable longitudinal register device

7. the imported frequency conversion control of motor for speed adopts to different printing speeds

8. there are "run"&“stop" buttons on the plate roller base and material drawing-in rack so as to make in easy for seperating the machine when the plate is installed.

|

Item/ Printing width

|

600MM

|

80MM

|

1000MM

|

1200MM

|

1400MM

|

1600MM

|

1800MM

|

2000MM

|

|||||||

|

Printing color

|

6 colours (PC:6+0; 5+1;4+2;3+2)

|

|

|

|

|

|

|

|

|||||||

|

Printing width

|

7.5"-40"/7.5"-50"/7.5"-60"/7.5"-70"/7.5"-80"

|

|

|

|

|

|

|

|

|||||||

|

Printing plate lifting system

|

Pneumatic/Hydraulic press control/Menu

|

|

|

|

|

|

|

|

|||||||

|

Mechanical speed

|

100m/min

|

|

|

|

|

|

|

|

|||||||

|

Printing speed

|

80m/min

|

|

|

|

|

|

|

|

|||||||

|

Anilox cylinder

|

Metal: 10DK-120DK (Germany)

|

|

|

|

|

|

|

|

|||||||

|

Register precision

|

Longitude:±0.25mm Transverse:±0.25mm

|

|

|

|

|

|

|

|

|||||||

|

Rewinder/Unwinder DIA

|

Φ 600mm

|

|

|

|

|

|

|

|

|||||||

|

Master motor (kw)

|

3.7

|

3.7

|

5.5

|

5.5

|

7.5

|

7.5

|

11

|

11

|

|||||||

|

Unwinder motor (kw)

|

1.1

|

1.1

|

1.5

|

1.5

|

2.2

|

2.2

|

3.0

|

3.0

|

|||||||

|

Rewinder motor (kw)

|

1.5

|

1.5

|

2.2

|

2.2

|

3.0

|

3.0

|

3.7

|

3.7

|

|||||||

|

Electrical header (kw)

|

14

|

16

|

20

|

22

|

24

|

26

|

28

|

30

|

|||||||

|

Blower of heater(kw)

|

1.5*2

|

1.1*3

|

1.1*3

|

1.1*3

|

1.5*3

|

1.5*3

|

2.2*3

|

2.2*3

|

|||||||

|

Blower of nature wind (kw)

|

0.75

|

0.75

|

1.1

|

1.1

|

1.1

|

1.5

|

1.5

|

1.5

|

|||||||

|

Inking motor (W)

|

750

|

750

|

750

|

750

|

750

|

750

|

750

|

750

|

|||||||

|

Master frequency converter

|

Panasonic/ Toshiba transducer Japan

|

|

|

|

|

|

|

|

|||||||

|

Bearing

|

Janpan (NSK)

|

|

|

|

|

|

|

|

|||||||

|

Unilateral bearling

|

ASNU(Germany)

|

|

|

|

|

|

|

|

|||||||

|

Weight(kg)

|

4500

|

4750

|

5000

|

5250

|

5500

|

5750

|

6000

|

6300

|

|||||||

|

Total power(kw)

|

25

|

27

|

34

|

37

|

43

|

47

|

55

|

58

|

|||||||

|

Dimension(L*W*H)m

|

4.8*1.8*2.8

|

4.8*2.0*2.8

|

4.8*2.2*2.8

|

4.8*2.4*2.8

|

4.8*2.6*2.8

|

4.8*2.8*2.8

|

4.8*3.0*2.8

|

4.8*3.2*2.8

|

|||||||

Hot Searches