- The variable pump control system is 25%-45% higher than the conventional machine; the servo control system is higher than usual 30-50% power saving for regulated machines.

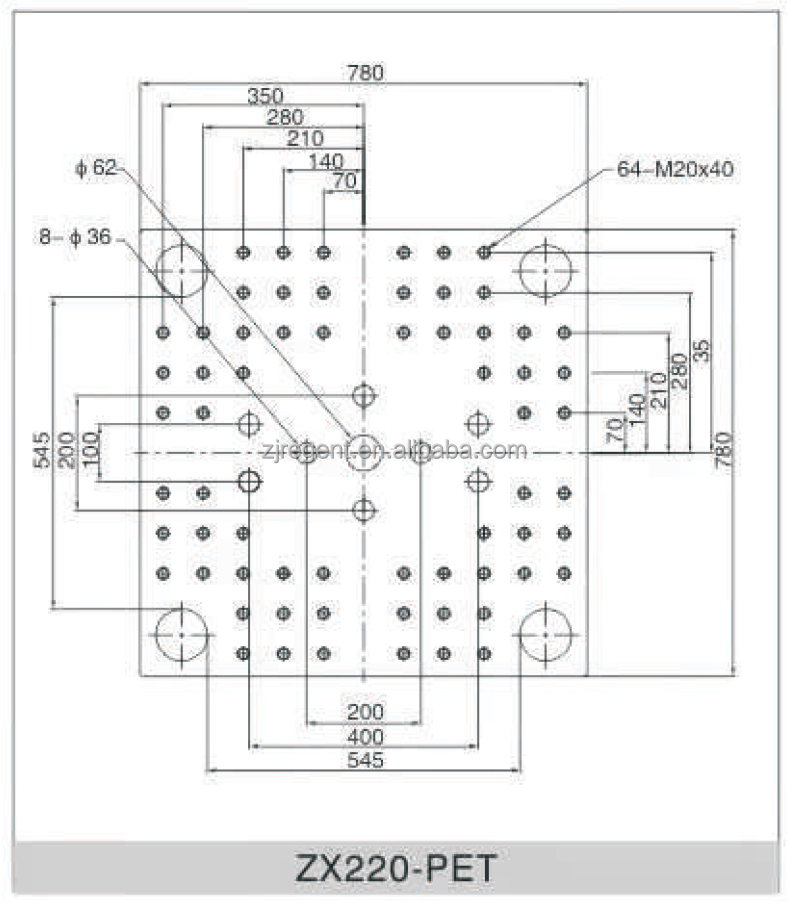

- The machine specifications are complete, adapt to variety of different preforms, the current maximum injection volume: 5000g.

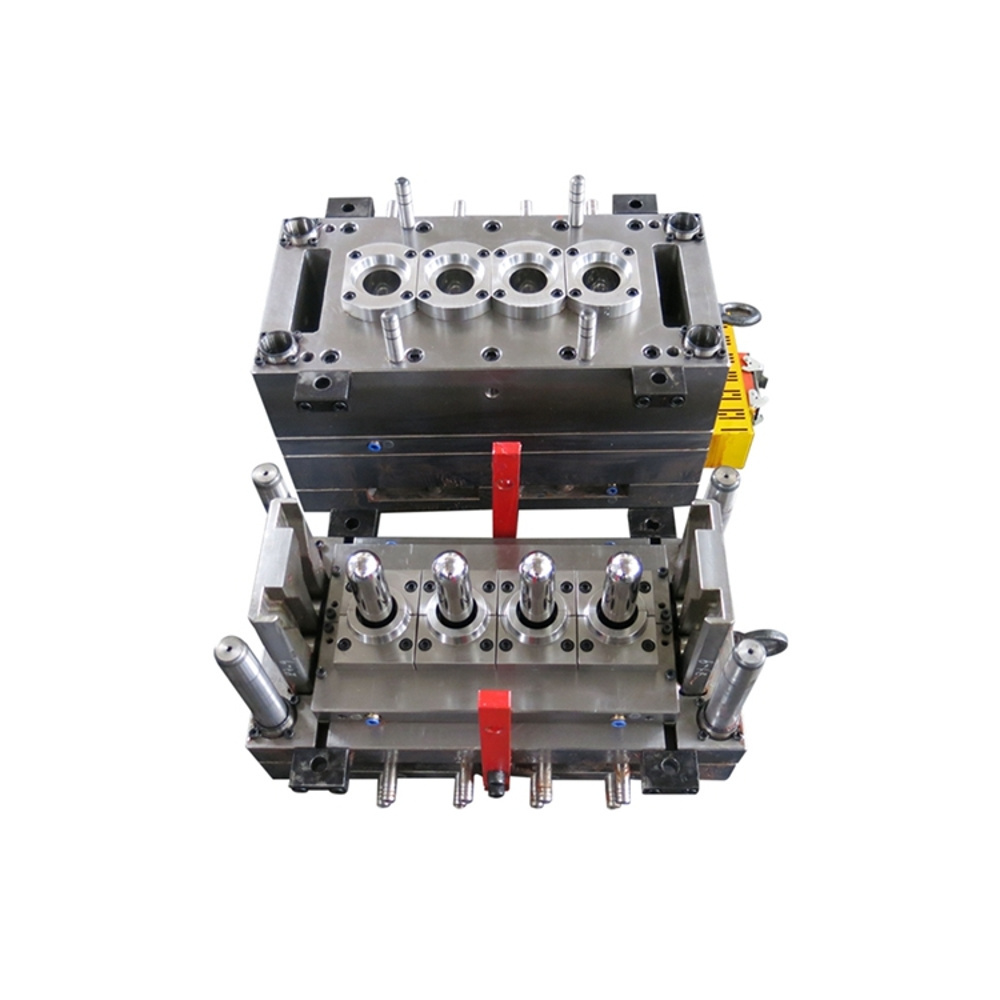

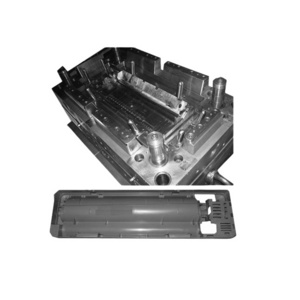

- Increase the ejection force and ejection stroke to meet the requirements of the preforms.

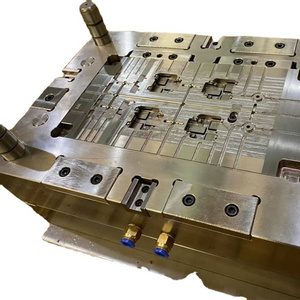

- The clamping part is fully encapsulated with sheet metal structure. Meets hygiene and temperature control requirements.

- With mold needle valve control interface.

- Optional synchronous pressure holding system can increase productivity by 15-25%.

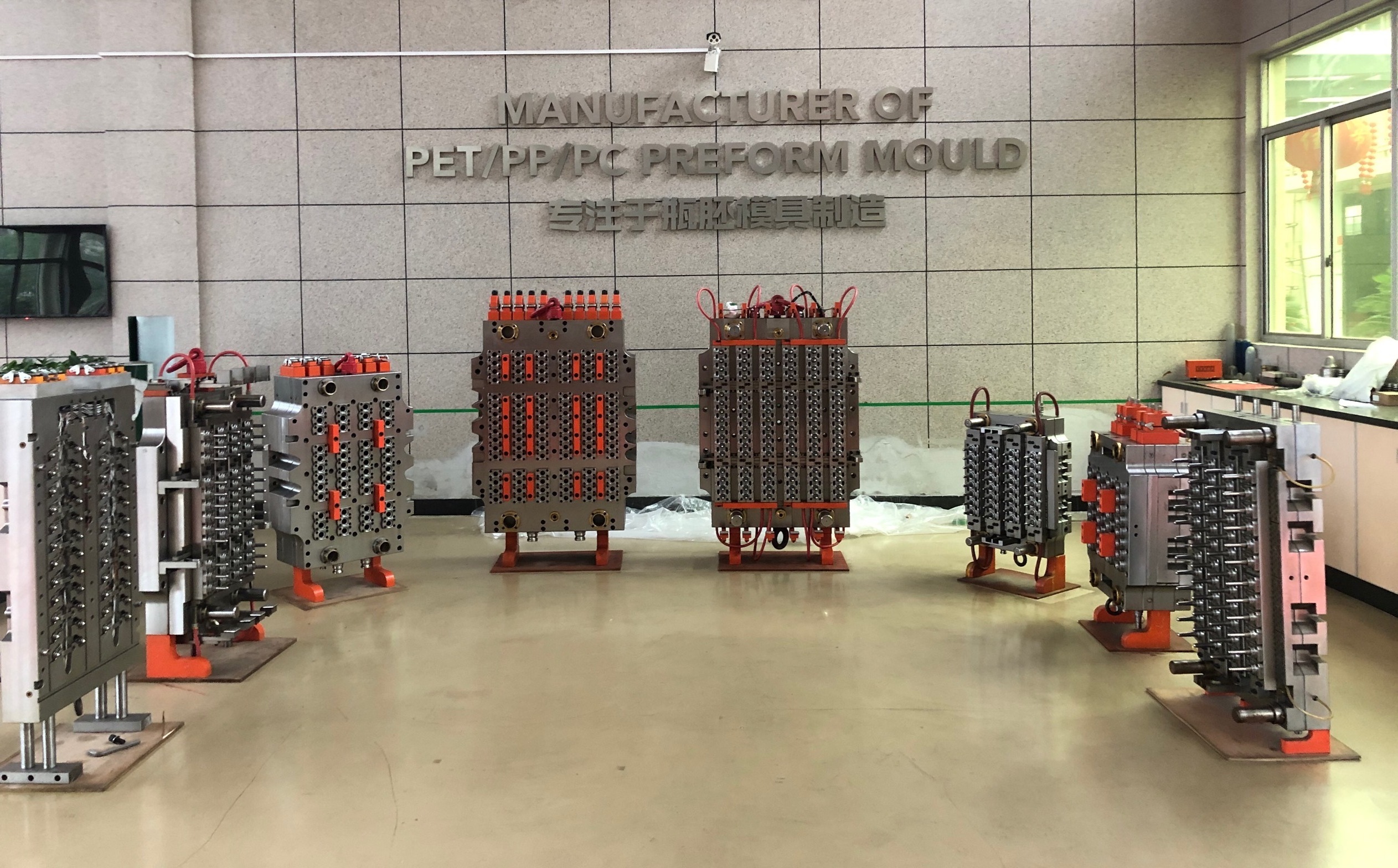

- A full set of PET bottle production technology and equipment can be provided, including: injection molding machine, blow molding machine, mold tools and other related equipment.

- Leading technology for the pressure valve unit, so that the melting and pressure action simultaneously, shorten the molding cycle time.