- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

tank body

-

usage:

-

beer fermentation tank

-

capacity:

-

1500Liter

-

tank design pressure:

-

0.15Mpa

-

jacket design pressure:

-

0.35Mpa

-

inlet & outlet:

-

1~3" tri-clamp, flange

-

interior wall polish:

-

mirror polish

-

exterior wall polish:

-

matt polish or sand blasting

-

cooling medium:

-

glycol

-

cooling jacket type:

-

dimple

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ranking

-

Weight:

-

190 KG

-

Core Components:

-

tank body

-

usage:

-

beer fermentation tank

-

capacity:

-

1500Liter

-

tank design pressure:

-

0.15Mpa

-

jacket design pressure:

-

0.35Mpa

-

inlet & outlet:

-

1~3" tri-clamp, flange

-

interior wall polish:

-

mirror polish

-

exterior wall polish:

-

matt polish or sand blasting

-

cooling medium:

-

glycol

-

cooling jacket type:

-

dimple

10BBL beer fermenter with conical bottom 1500L beer fermenter

Ranking Machinery mainly offer beer fermenters from 200Liter to 8600Liter according touser's reqeust.

Making beer is a surprisingly complicated process. Beer production encompasses five main stages

1. malting, the germination of barley grains;

2. mashing, a stepwise heating process to promote starch hydrolysis;

3. wort boiling with hops;

4. fermentation;

Fermentation. The wort is inoculated with a special strain of Saccharomyces cerevisiae known as brewer’s yeast. The yeast conducts ethanolic fermentation on the maltose from hydrolyzed starch. At the same time, minor by-products, such as long-chain alcohols, impart good flavors. The time of fermentation is a key factor in the quality of the beer.

5. postfermentation treatments.

10BBL Beer Fermenter/Fermentation Tank

- SUS 304/ 316L with 20%-25% head space;

- Dimple plate jacket for Glycol Cooling

- Mirror polished interior surface and Satin Polished Exterior surface

- Can made according to customer’s request

Features include:

- With 25% Head Space beside the working volume10bb

- 100% Stainless Steel 304 Construction;

- Shadowless Manway

- Thru the Wall Spray Ball with CIP Line

- 1″ Rotating Racking Arm with 1 1/2″ TC Butterfly Valve

- 2″ Pull Handle Butterfly for Drain with Elbow and 12″ Spool to outside wall

- Thermometer with Thermowell

- Sample Valve

- 3mm Thickness Tanks

- 60 Degree Conical Bottom

- 2 extra 1 1/2″ ferules on top for accessories

- Dimple Jacketed, Insulated Polyurethane Filled;

Optional Features:

- Pressure Relief/Vacuum

- Valve Available

- Carbon Stone Available

- Extra Ferules installed per ferule 1″ thru 3″ sizes

- Sight Level Glass with 2 valves Installed;

- Oval Manway 430mm x 330mm (550mm x 430mm) with Seal on side;

beer fermenters picture with different capacity

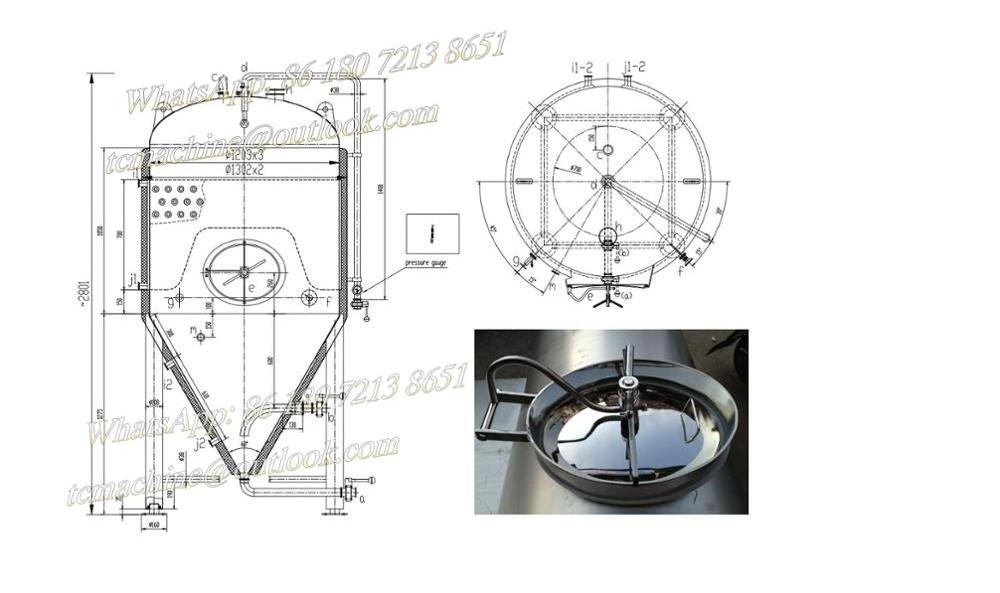

10BBL beer fermenter 1500L stainless steel beer fermenter with conical bottom specification

Technical Paraeter

| Item | inside the fermenter | in the jacket |

| Construction material | stainless steel 304 | stainless steel 304 |

| Design Pressure | 1.5bar | 3.5bar |

| Design Temperature | 100 Degree Celsius | 65 Degree Celsius |

| Fermentation tank capacity | 10BBL |

Orifice table for 10BBL beer fermenter 1500Liter beer fermentation tank

| Symble | Nominal size | Connection | Description |

| a | 1.5"~2" | Tri-clamp | Outlet |

| b | 1.5"~2" | Tri-clamp | Outlet |

| c | 1.5"~2" | Tri-clamp | Relief valve |

| d | 4" | Tri-clamp | hop port |

| e | 2.5"-1.5" | Tri-clamp | Cleaning hole |

| f | Φ450×350 | Quick-opened | Manway |

| g | 1.5" | Tri-clamp | Thermometer |

| h | 1.5" | Tri-clamp | Sampling valve |

| i | 1.5" | Tri-clamp | Glycol outlet |

| j | 1.5" | Tri-clamp | Glycol inlet |

| k | 1.5" | Tri-clamp | CO2 connection |

10BBL beer fermenter drawing from ranking machinery

nylon packing or iron packing according to the beer fermenter quantity and capacity.