- Product Details

- {{item.text}}

Quick Details

-

Warranty of core components:

-

1year

-

keyword:

-

corn flour milling machine

-

keyword 1:

-

corn mill machine for sale ghana

-

keyword 2:

-

small scale maize milling machine sorghum milling machine

-

function:

-

crusher grain, corn ,spice into powder,small particles

-

Raw material:

-

corn, bean, rice, wheat,grain, spice.so on

-

type:

-

Toothed claw

-

After-sales Service Provided:

-

Online Service

-

final product size:

-

adjustable

-

factory visit:

-

welcome

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V/customized

-

Weight:

-

50 KG

-

Warranty of core components:

-

1year

-

keyword:

-

corn flour milling machine

-

keyword 1:

-

corn mill machine for sale ghana

-

keyword 2:

-

small scale maize milling machine sorghum milling machine

-

function:

-

crusher grain, corn ,spice into powder,small particles

-

Raw material:

-

corn, bean, rice, wheat,grain, spice.so on

-

type:

-

Toothed claw

-

After-sales Service Provided:

-

Online Service

-

final product size:

-

adjustable

-

factory visit:

-

welcome

Product Description

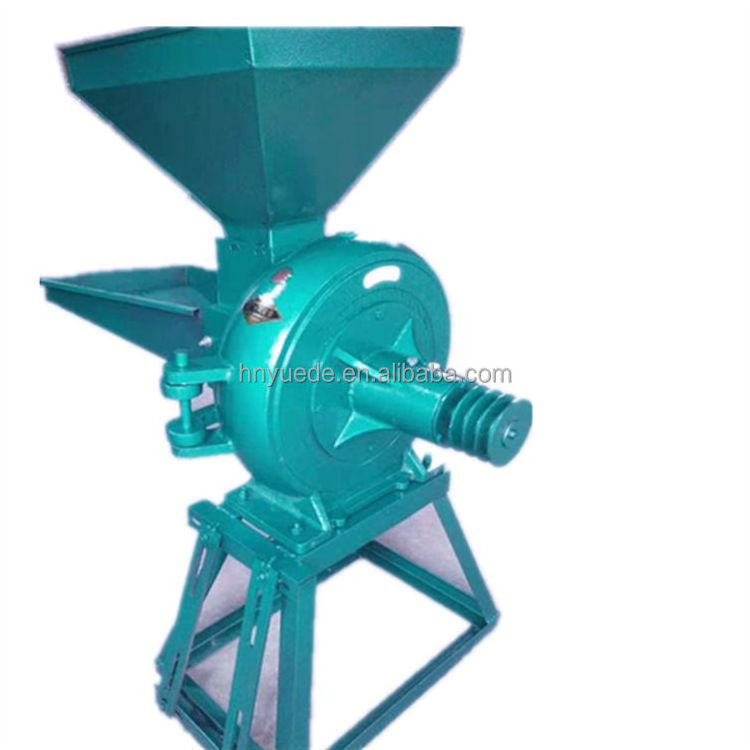

Tooth claw crusher/grinder/milling machine

tooth claws grinder machine/ mill machine is a kind of machine that uses high-speed rotating teeth and claws to grinder feed, which has the advantages of small size, light weight, fine product particle size, high working speed, installation, operation and easy maintenance

Application: It can be used for grinding grain, corn bean,wheat and so on granular raw material into powder/small particles.

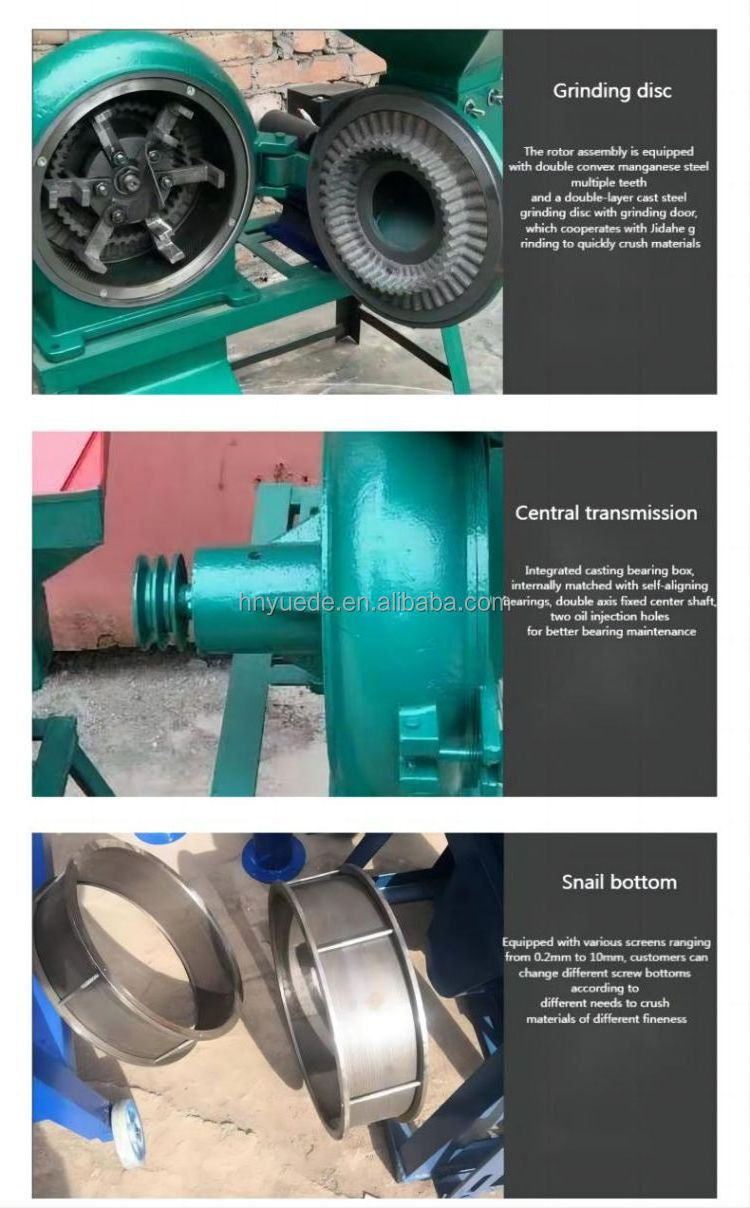

Working principle :

When working, the processed material from the hopper into the pulverization chamber, by the high-speed rotation of the working parts of the blow and fragmentation, while changing the direction of movement of the material, due to the high-speed rotation of the working parts destroyed the deposition of the material layer, therefore, the material with the rotor movement, in this process, the particles are repeatedly affected by the collision of the working parts and the body and the collision between the particles, friction, so that the gradual pulverization to its geometric diameter is less than the diameter of the sieve hole, under the action of centrifugal force and air flow, The crushed material is discharged from the outlet through the sieve leakage chamber. In this kind of machine, the grinding fineness is determined by the pore size of the sieve hole. Users can reasonably choose the screen according to the granularity requirements of the feed.

Specification

|

Model

|

160

|

280

|

300

|

320

|

360

|

|||||

|

rotor diameter

|

160

|

280

|

300

|

320

|

350

|

|||||

|

Single hammer quantity

|

3

|

3

|

3

|

5

|

5

|

|||||

|

Number of double hammers

|

3

|

3

|

3

|

5

|

5

|

|||||

|

power (kw)

|

1.5-2.2

|

2.2-3

|

3/4.5/5.5

|

5.5/7.5/11.5

|

7.5/11/15

|

|||||

|

capacity (kg/h )

|

50-100

|

150-300

|

200-350

|

300-500

|

500-1000

|

|||||

|

size (mm)

|

700*500*300

|

800*650*300

|

900*700*300

|

1150*550*400

|

1150*580*450

|

|||||

|

Main machine weight(kg)

|

30

|

50

|

60

|

110

|

150

|

|||||

|

Screen mesh: there is different specification,we match suitable according to client's need

|

|

|

|

|

|

|||||

Hot Searches