- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JINER TAI

-

Model Number:

-

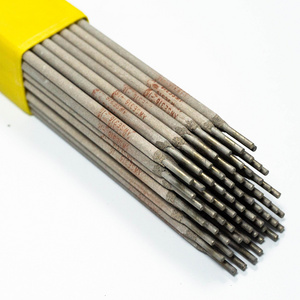

A5.4 E316L-16

-

Operating Current:

-

130-220A, AC DC+

-

Application:

-

stainless steel structure

-

Dia:

-

2.0,2.5,3.2,4.0,5.0mm

-

Package:

-

2.0kg/box,10kgs/carton

-

Keyword:

-

welding electrode

-

Usages:

-

stainless steel structure

-

OEM:

-

Accept

-

Sample:

-

Available

-

Welding positions:

-

PA,PB,PD,PF

-

Welding Current::

-

AC DC+

-

Type:

-

rutile type

Quick Details

-

Material:

-

Stainless Steel

-

Welding Current:

-

International Standard

-

Operating Temperature:

-

30℃

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JINER TAI

-

Model Number:

-

A5.4 E316L-16

-

Operating Current:

-

130-220A, AC DC+

-

Application:

-

stainless steel structure

-

Dia:

-

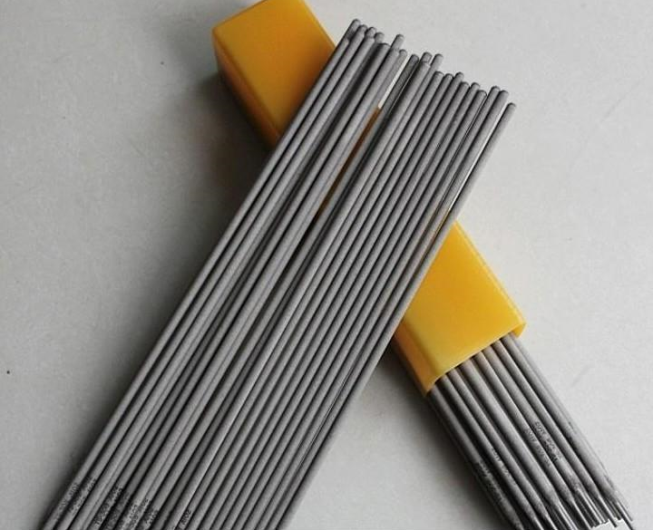

2.0,2.5,3.2,4.0,5.0mm

-

Package:

-

2.0kg/box,10kgs/carton

-

Keyword:

-

welding electrode

-

Usages:

-

stainless steel structure

-

OEM:

-

Accept

-

Sample:

-

Available

-

Welding positions:

-

PA,PB,PD,PF

-

Welding Current::

-

AC DC+

-

Type:

-

rutile type

NAME

AWS A5.4 E316L-16 Stainless Steel Welding Electrode

WELDING POSITIONS: PA,PB,PD,PF

TYPICAL OPERATING PROCEDURES:(AC,DC+)

|

Diameter in (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

|

Current in (A) |

25-50 |

50-80 |

80-110 |

110-160 |

160-200 |

DEPOSIT COMPOSITION(Quality Score): %

|

items |

C |

Cr |

Ni |

Mo |

Mn |

Si |

P |

S |

Cu |

|

Requir-ements |

≤0.04 |

17.0-20.0 |

11.0-14.0 |

2.0-3.0 |

0.5-2.5 |

≤1.00 |

≤0.04 |

≤0.03 |

≤0.75 |

|

Typical Results |

0.026 |

18.40 |

12.80 |

2.20 |

1.08 |

0.62 |

0.022 |

0.010 |

0.08 |

MECHANICAL PROPERTIES:

|

items |

Tensile Strength Rm/MPa |

Elongation A/% |

Charpy V-Notch KV 2 (J)-196℃ |

|

Requirements |

≥490 |

≥25 |

≥29 |

|

Typical Results |

579 |

37.6 |

36 |

2.0kg /box,10kgs/carton

Quality first and customer is supreme. To the quality strives for the survival To the brand strives for the development Challenges the market by the first-class product quality.

APPLICATIONS:

It is suitable for the welding of area, petroleum chemical industry, synthetic fiber production equipment and the same type of stainless steel structure, also can be used for chromium stainless steel and composite steel and dissimilar steel and so on, which can not be heat treatmented after welding .It can be used for stainless steel structure using under cryogenic temperatures, such as liquid nitrogen container, liquefied natural gas containers, etc.

ATTENTION:

1.Electrode must be approved by 320-350 ℃ for 1 hour before welding, dry the electrode when use it .

2. The rust, oil, water and other impurities of the weld must be removed before welding.

3.Recommended DC power supply, because AC welding has a shallow penetration, the current should not be too large, in order to avoid the coating redness and cracking.

4. To minimize the amount of heat input and welding electrode oscillating amplitude shoulds not be too big.

5.Preheat and interlayer-temperature should remain below 150 ℃