- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DM-HT718

-

Type:

-

One Component

-

Application:

-

Automobile windshield bonding/Construction/Decoration/Industry

-

Color:

-

Black/White/Grey

-

Certificate:

-

ISO9001:2008

-

Shelf life:

-

12 Months

-

Advantage:

-

High Bonding

-

Component:

-

Single Component

-

Viscosity:

-

Excellent Viscosity

-

Solvent:

-

Solvent-free

Quick Details

-

EINECS No.:

-

203-652-6

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dimei

-

Model Number:

-

DM-HT718

-

Type:

-

One Component

-

Application:

-

Automobile windshield bonding/Construction/Decoration/Industry

-

Color:

-

Black/White/Grey

-

Certificate:

-

ISO9001:2008

-

Shelf life:

-

12 Months

-

Advantage:

-

High Bonding

-

Component:

-

Single Component

-

Viscosity:

-

Excellent Viscosity

-

Solvent:

-

Solvent-free

Product Description

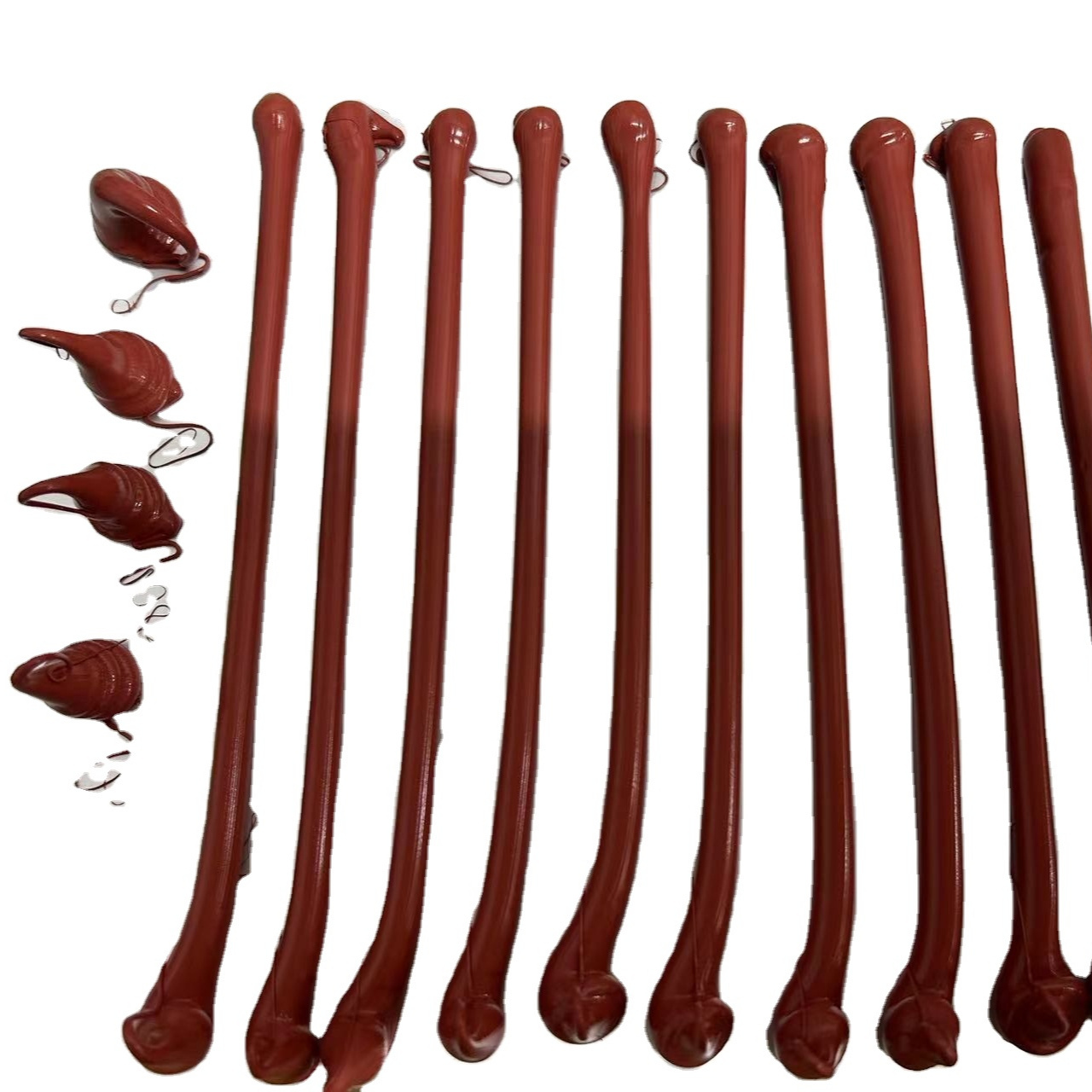

DM-HT718 RTV silicone sealant (high temperature resistant to 300℃)

DM-HT718 is a condensation-type one-component room temperature vulcanized silicone rubber,

The condensation reaction with moisture in the air releases low molecular weight to cause cross-linking, and then solidifies into a high-performance elastomer

Precautions

A small amount of solidification may appear at the mouth of the nozzle during use, and it can be used normally after being removed without affecting product performance;

After the operation is completed, the unused glue should be tightened immediately and the cap should be sealed and stored;

There is a slight irritating smell released during the curing process, pay attention to the ventilation of the working area.

Specification

|

Performance

|

Standard

|

Item No. DM-HT718

|

||

|

Outer appearance

|

Visual inspection

|

Paste

|

||

|

Density(g/cm³)

|

GB/T 13477.2-2002

|

1.05±0.05

|

||

|

Viscosity(mPa·s)

|

GB/T2794-1995

|

/

|

||

|

Surface dry time (min)

|

GB/T 13477.5-2002

|

5~20minutes(25℃,50%RH)

|

||

|

Full curing time (d)

|

GB/T 13477.5-2002

|

1~3

|

||

|

Tensile strength(MPa)

|

GB/T 528-2009

|

≥2.0

|

||

|

Elongation at break(%)

|

GB/T 528-2009

|

≥200

|

||

|

Hardness(Shore A)

|

GB/T 531.1-2008

|

25~35(shoreA)

|

||

|

Shear strength(MPa)

|

GB/T 11211-2009

|

≥1.5(L-L)

|

||

|

volume resistivity(Ω·cm3)

|

GB/T 1692-2008

|

3.0×1014

|

||

|

Breakdown strength(Kv/mm)

|

GB/T 1695-2005

|

20

|

||

|

Dielectric constant(60Hz)

|

GB/T 1693-2007

|

2.3

|

||

|

Dielectric loss factor(60Hz)

|

GB/T 1693-2007

|

2.0×10-3

|

||

|

Operating temperature range(℃)

|

|

-60~300

|

||

|

Mechanical properties, curing in air for three days at 25°C and 50% relative humidity

|

|

|

||

Advantages

Excellent resistance to cold and heat changes, stress changes and other properties.

High and low temperature resistance, long-term elasticity and stability at -60 to 300°C after curing.

Ultraviolet resistance, aging resistance, and excellent insulation, moisture resistance, shock resistance, corona resistance, leakage resistance and chemical medium resistance.

No corrosion, no solvent, fast curing, low odor.

Comply with the requirements of the EU ROHS directive.

Storage

Shelf life: 12 months in unopened packing, since the production date.

Recommended storing temperature: 10℃~25℃ (not >45℃).

*Dry and cool condition can help to postpone the shelf-life.

*The shelf-life may be change rely on special packing materials.

*Please refer to the MSDS when handling, and also complying with rules of local law.

Shelf life: 12 months in unopened packing, since the production date.

Recommended storing temperature: 10℃~25℃ (not >45℃).

*Dry and cool condition can help to postpone the shelf-life.

*The shelf-life may be change rely on special packing materials.

*Please refer to the MSDS when handling, and also complying with rules of local law.

Product Applications

Application area

High-strength bonding of metal, glass, plastic, ceramics, rubber, etc.

Adhesion and sealing of household appliances, kitchen appliances, instruments and meters, electronic appliances and other industries.

A variety of applications that require bonding or sealing in other industries.

Application tips

The bonded surface must be clean, dry and free of putty before bonding.

Substrates that may seep out of oil are not suitable for direct application of sealant.

For rusted or corroded metal surfaces (such as aluminum oxide, copper, iron oxide rust surface), in order to ensure the bonding effect, the rust on the surface layer needs to be worn off before coating.

Due to the construction environment, construction methods, and material differences, pre-testing is required before use to ensure adhesion performance.

The optimal coating temperature is +5 ~ +40°C. When the temperature is low, the extrusion resistance

Packing & Delivery

Packing

5gal/bucket 2.6L/tube 300ml/cartridge 45ml/tube

5gal/bucket 2.6L/tube 300ml/cartridge 45ml/tube

Recommend Products

Hot Searches