- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800*1200*1350mm

-

Weight:

-

600 KG

-

Product name:

-

magnetic separator

-

Application:

-

ore concentration,magnetic separation

-

Feeding size:

-

0-6mm

-

Capacity:

-

10-20tph

-

Material:

-

Steel

-

Motor:

-

Chinese Famous Brand

-

Installation:

-

Engineer Guide

-

Usage:

-

Mining Concentration

-

Local Service Location:

-

None

-

Certification:

-

ISO9001:2008

Quick Details

-

Production Capacity:

-

10-20t/h

-

Place of Origin:

-

China

-

Brand Name:

-

JINCHUAN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800*1200*1350mm

-

Weight:

-

600 KG

-

Product name:

-

magnetic separator

-

Application:

-

ore concentration,magnetic separation

-

Feeding size:

-

0-6mm

-

Capacity:

-

10-20tph

-

Material:

-

Steel

-

Motor:

-

Chinese Famous Brand

-

Installation:

-

Engineer Guide

-

Usage:

-

Mining Concentration

-

Local Service Location:

-

None

-

Certification:

-

ISO9001:2008

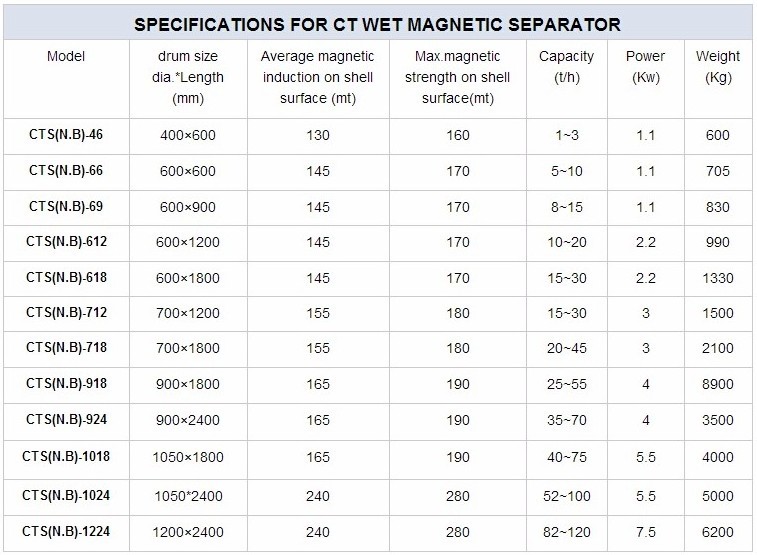

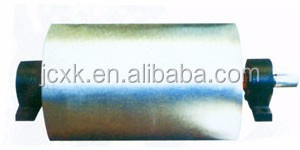

Product Application

JINCHUAN Wet Drum Permanent Magnetic Separator is suitable for Mine, Coal preparation plant etc. use weak wet magnetic field to sort out the strong magnetic ore, or eliminating the strong magnetic minerals mixed in nonmagnetic minerals. The magnetic field of CTS(N,B) wet drum permanent magnetic separators divide into rotary and fixed. The fixed one is mainly use in weak magnetic field to separate the fine particle strong magnetic materials, or eliminating the strong magnetic materials in the nonmagnetic ores.

Main Features

1. simple structure

2. Easy-open structure gives a convenient cleaning;

3. large handling

4. magnetic intensity: 800 to 11000 Gauss

5. easy to operate

6. The number of axial magnetic can be adjusted in accordance with material characteristics;

7. easy to maintain

8. This magnetic separator is suitable for processing various bulk materials and will not blocked for its compact structure.

9. Low power

10. Also has disaggregating function for sticky and poor-fluidity powders;

11. Stainless steel machine and full-closed operation enable an easy clean;

12. This high gradient magnetic separator has optimized magnetic circuit, which offers high intensity magnetic field for better separating effect.

13. Magnetic separator working under high temperature

Main features

This wet drum permanent magnetic separator can continuously feeding ores and discharge ores ,with large magnetic field intensity, high magnetic field gradient, big working clearance, higher processing ability and little magnetic flux leakage, low energy consumption, fine beneficiation results, simple structure and easy to maintain.

Working princple

When the ore pulp entering magnetic field area, the ferromagnetic materials are sucked up on the surface of the drum, weak magnetic substance and nonmagnetic minerals are washed away by water, the absorbed magnetic minerals on the surface of drum are rotated with the drum and taken out of magnetic field area .The rotary one is suitable to dry separate the fine particle strong magnetic ore, because of speedy rotation, the magnetic particle rolling more times than other magnetic separator, which is effectively destroy the reunite of magnetic and arise the high-grade ore, the ore are divide into magnetic and nonmagnetic after separation, and discharge from the own road. This machine is suitable for the roughing and cleaning of particle size in 6-0mm size.

Different kinds of wet magnetic machine

This machine has three kinds of tank: CTB, CTS and CTN, the same kind of drum could match those three tanks, to suitable different separation work and different requirement:

l CTS is suitable for the roughing and cleaning of particle size in 6-0mm;

l CTN is suitable for the cleaning and scavenging of fine particle size in 0.6-0mm , and it is often applied to recycle heavy medium in coal;

l CTB is suitable for the roughing and cleaning of ores in size of 0.5-0mm, especially suitable for the cleaning of ores in size of 0.15-0mm.

Applications

Magnetic separator is ideally used to separate ferrous particles from non ferrous particles. Magnetic Separator is designated for wet magnetic separating of material with granularity below 3mm, such as magnetite, pyrrhotine, roasted ore and washingtonite. It can also be used for deironing of coal, nonmetal materials, building materials, etc.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.