- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUSSMAN

-

Voltage:

-

380v/220v

-

Dimension(L*W*H):

-

9500X800X1200MM

-

Weight:

-

8000 kg

-

Marketing Type:

-

competitive price

-

Material thickness:

-

0.3-0.8mm galvanized steel

-

Producting speed:

-

5-12m/min

-

Roller station:

-

About 24 stations

-

Main Power:

-

7.5KW servo motor

-

Cutting method:

-

Hydraulic Cutting Cr12mov

-

Material of Shaft:

-

45# steel

-

Way Of Drive:

-

Chain drive

-

Roller material:

-

45# forged steel, surface coated with chrome

-

Hydraulic Station Power:

-

7.5KW

-

Control system:

-

PLC(imported Brand)

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Galvanized steel sheet

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUSSMAN

-

Voltage:

-

380v/220v

-

Dimension(L*W*H):

-

9500X800X1200MM

-

Weight:

-

8000 kg

-

Marketing Type:

-

competitive price

-

Material thickness:

-

0.3-0.8mm galvanized steel

-

Producting speed:

-

5-12m/min

-

Roller station:

-

About 24 stations

-

Main Power:

-

7.5KW servo motor

-

Cutting method:

-

Hydraulic Cutting Cr12mov

-

Material of Shaft:

-

45# steel

-

Way Of Drive:

-

Chain drive

-

Roller material:

-

45# forged steel, surface coated with chrome

-

Hydraulic Station Power:

-

7.5KW

-

Control system:

-

PLC(imported Brand)

Product Description

|

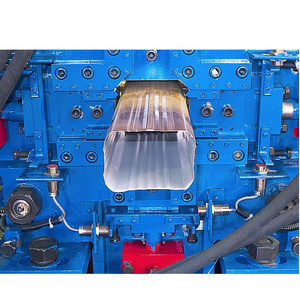

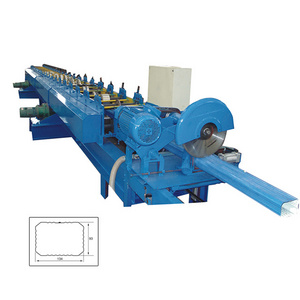

Forming stations:

|

About 24 stations or according to you profile drawings

|

|

Machine structure:

|

Wall panel structure

|

|

Material thickness

|

0.3-0.8mm

|

|

Forming speed

|

5-12m/min (EXCLUDING CUTTING STOP TIME)

|

|

Main motor power

|

7.5KW

|

|

Hydraulic station power

|

7.5KW

|

|

Rollers material :

|

45# forged steel, surface coated with chrome

|

|

Way of drive :

|

Chain drive

|

|

Raw material request:

|

Galvanized steel,PPGI, Aluminum

|

|

Cutting blade material

|

Cr12Mov quenching treatment

|

|

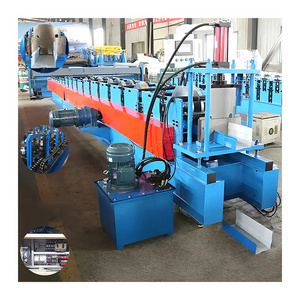

Electrical controlling system

|

Whole line adopted PLC control, cut to length tolerance≤2mm

|

|

Inverter :

|

Yaskawa,Siemens,Mitsubishi, panasonic (option Brand)

|

|

PLC :

|

Yaskawa,Siemens,Mitsubishi, panasonic (option Brand)

|

|

Serial No.

|

Commodity & Description

|

Quantity

|

|

1

|

3T manual uncoiler

|

1 set

|

|

2

|

Feeding with guide

|

1 set

|

|

3

|

Main roll forming machine

|

1 set

|

|

4

|

Straighten device

|

1 set

|

|

5

|

Hydraulic cutting equipment

|

1 set

|

|

6

|

Output table

|

1 set

|

|

7

|

Main drive

|

1 set

|

|

8

|

Hydraulic system

|

1 set

|

|

9

|

Controlling system (including cabinet)

|

1 set

|

|

10

|

Downpipe elbow bending machine

|

1 set

|

|

11

|

Seaming machine

|

1 set

|

|

12

|

Safety cover

|

1 set

|

|

13

|

Spare parts

|

1 package

|

Detailed Images

Decoiler:3 tons passive coiler

Coil inner Diameter: ¢460mm~520mm

Max out diameter of the coil: ¢800mm

Expansion: with 4 palms, with brake

Max Coil Width: 500mm

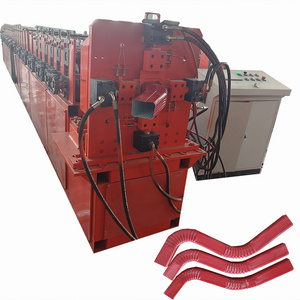

Elbow and bending

1. The cutter blade material: Cr12mov HRC58-62 degree

2. Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

3.Length measuring: Automatic length measuring

Power supplier: 380V, 50 Hz, Three Phase (adjusted with the requestment)

Length & quantity measurement automatically;

Length & quantity controlled by PLC

Length inaccuracy can be amended easily.

Control panel: Button-type switch and touch screen

The language in the touch screen: English and Chinese

Unit of length: millimeter (switched on the control panel)

Length & quantity measurement automatically;

Length & quantity controlled by PLC

Length inaccuracy can be amended easily.

Control panel: Button-type switch and touch screen

The language in the touch screen: English and Chinese

Unit of length: millimeter (switched on the control panel)

It adopts welded steel and supported roller to transmit the products.

Size:4000*1350*1000mm

Maintance and the service of the machine

Machine maintenance

Daily maintenance with meticulous care plays an important part in extension the equipments’ operation time and the quality of rolling plank. Therefore, please do the following things in your daily.

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when you use next time.

4. If the equipment does not use for long time, you should use plastics cloth or other articles to cover it and notice to avoid rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to the request

6. Usually look into hydraulic station and the oil quantity of deceleration machine, you should add in time when oil quantity shortage

7. Electrical components should be guaranteed to work in a dry environment, such as damp. Rain should continue to work after drying.

Our Company

Hot Searches