- Product Details

- {{item.text}}

Quick Details

-

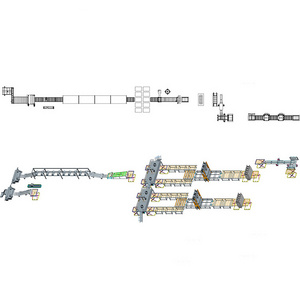

Dimension(L*W*H):

-

46500*2000*1400mm

-

Power (kW):

-

95kw

-

Weight (KG):

-

45 kg

-

Applicable Industries:

-

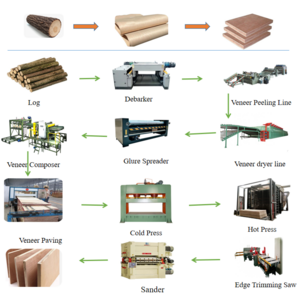

woodworking machinery of plywood production line

-

Name:

-

Veneer Peeling Machine

-

Model:

-

CFM1500SZ

-

diameter of peeler log:

-

30-400mm/500mm

-

Length of peeler log:

-

1000-1300mm

-

length of blade:

-

1500mm

-

Thickness of veneer peeler:

-

0.8-6mm

-

linear speed of host machine:

-

35-75m/min speed adjustable

-

diameter of driving roller:

-

118mm

-

Power of feeding motor:

-

7.5kw servo motor

-

power of pressure bar roller:

-

4kw*2

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sinoeuro

-

Voltage:

-

380V/415V

-

Dimension(L*W*H):

-

46500*2000*1400mm

-

Power (kW):

-

95kw

-

Weight (KG):

-

45 kg

-

Applicable Industries:

-

woodworking machinery of plywood production line

-

Name:

-

Veneer Peeling Machine

-

Model:

-

CFM1500SZ

-

diameter of peeler log:

-

30-400mm/500mm

-

Length of peeler log:

-

1000-1300mm

-

length of blade:

-

1500mm

-

Thickness of veneer peeler:

-

0.8-6mm

-

linear speed of host machine:

-

35-75m/min speed adjustable

-

diameter of driving roller:

-

118mm

-

Power of feeding motor:

-

7.5kw servo motor

-

power of pressure bar roller:

-

4kw*2

|

1. name

|

veneer peeling lathe with clipper

|

|

length of peeler log

|

1000-1400mm

|

|

diameter of peeler log

|

80-600mm

|

|

length of blade

|

1500mm

|

|

thickness of veneer peeler

|

1-3mm

|

|

linear speed of host machine

|

50m/min

|

|

total weight

|

4200kg

|

|

overall dimensions

|

3000*2200*1380

|

|

2. name

|

spindleless veneer lathe with clipper inside

|

|

length of peeler log

|

1000-1300mm

|

|

diameter of peeler log

|

30-400mm

|

|

length of blade

|

1500mm

|

|

thickness of veneer peeler

|

0.5-4mm

|

|

linear speed of host machine

|

35-75m/min speed adjustable

|

|

diameter of driving roller

|

118mm

|

|

power of feeding motor

|

7.5kw servo motor

|

|

total weight

|

5200kg

|

|

overall dimension

|

4500*2000*1400mm

|

|

3. name

|

8 ft face veneer spindleless veneer lathe

|

|

length of peeler log

|

2000-2600mm

|

|

diameter of peeler log

|

36-400mm

|

|

length of blade

|

2700mm

|

|

thickness of veneer peeler

|

0.3-1.8mm

|

|

diameter of driving roller

|

118mm

|

|

power of driving roller

|

7.5kw

|

|

power of cutting feed

|

7.5kw

|

|

total weight

|

5500kg

|

|

overall dimensions

|

5200*1800*1400mm

|

|

4. name

|

8 ft rotary peeling lathe

|

|

max slicing diameter

|

1500mm

|

|

slicer veneer thickness

|

0.1mm-2.6mm

|

|

slicer length

|

2000mm-2600mm

|

|

peeling speed

|

0-80m/min

|

|

remain wood core diameter

|

120mm

|

|

electronic parts brand

|

Schneider

|

|

total weight

|

8000kg

|

|

dimension

|

6500mm*2350mm*2600mm

|

|

5. name

|

8ft horizontal rotary peeling lathe

|

|

max slicing diameter

|

900mm

|

|

slicer veneer thickness

|

0.1mm-2.6mm

|

|

slicer length

|

2000mm-2600mm

|

|

peeling speed

|

0-80m/min

|

|

remain wood core diameter

|

90mm

|

|

total weight

|

7900kg

|

|

overall dimension

|

6500mm*2350mm*2600mm

|

|

6.name

|

glue spreader

|

|

max. processing length

|

1400mm

|

|

rubber roller diameter

|

250mm

|

|

max. working thickness

|

70mm

|

|

weight

|

1000kgs

|

|

overall dimension

|

2200*1200*1400

|

|

7.name

|

glue mixer

|

|

bucket size

|

800*800mm

|

|

max capacity

|

100kgs/time

|

|

motor power

|

380V,2.2KW

|

|

weight

|

100kgs

|

|

8.name

|

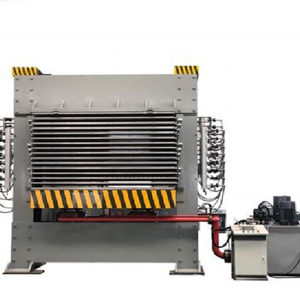

cold press

|

|

total pressure

|

500T or as your requirements

|

|

layers

|

1

|

|

work plate size

|

2700*1370mm

|

|

stroke

|

1000mm

|

|

working methods

|

full automatic

|

|

weight

|

13T

|

|

overall dimension

|

3550*1370*4200mm

|

|

name

|

hot press

|

|

board feeding direction

|

transverse

|

|

number of layers

|

15 layers or as your requirements

|

|

layer spacing between plate

|

70mm

|

|

hot press plate size

|

1370*2700*42/52mm

|

|

stroke

|

1200mm

|

|

low pressure pump flow

|

250 oil pump*2(l/min)

|

|

working methods

|

full automatic

|

|

weight

|

about 40T

|

|

overall dimention

|

3700*1370*4600mm

|

|

10.name

|

Automatic double sizer saw

|

|

Long saw cutting size

|

2440mm(adjustable)

|

|

Lateral saw cutting size

|

1220mm(adjustable)

|

|

Feed Way

|

Full Automatic

|

|

Work Methods

|

Full Automatic

|

|

Working speed

|

10—30m/min

|

|

Power

|

42KW

|

|

Saw blade dimension

|

Diameter 305mm,Inner diameter 25.4mm

|

|

Weight

|

5000kgs

|

|

Overall dimension

|

8000×5000×1200mm

|

|

11.name

|

Wide Belt sander 2 heads sander

|

|

Working width

|

40-1300mm

|

|

Working thickness

|

2-100mm

|

|

Working length

|

≥630mm

|

|

Feed speed

|

6-30m/min

|

|

Main motor

|

37kw, 22kw

|

|

Total motor power

|

59kw

|

|

Speed of dust collecting

|

25-30m/s

|

|

Total weight

|

3700kg

|

|

Overall dimension (LxWxH)

|

2360x2030x2220

|

Pre-sale

1.Free consultation about the equipment.

2.Reasonable purchasing plan and the production line designing plan are offered according to the clients' special requirment to help you to select the most suitable machinery.

3.Welcome to visit our factory and check our machine.

During-sales

1. We inspect and test the machine before delivery.

2.We are willing to freely tran your technicist and first-line operator.

After-sales

1.Engineers are available to service overseas.

2.Videos about installing and debuging the equipment

.

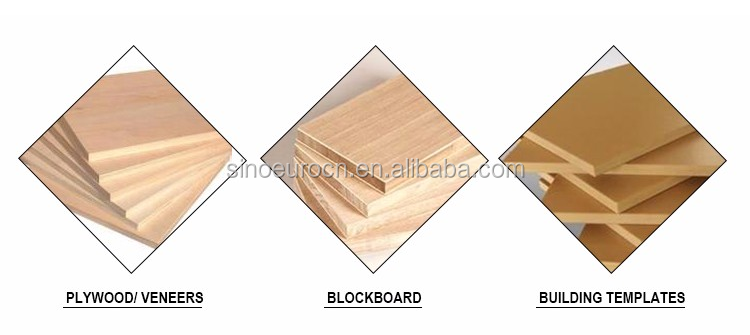

Sinoeuro Group

is a manufacturer of wood working machinery with well equipped testing facilities and strong technical force.

1. Leading manufacturer of woodworking machinery in China, found

in 1994

. specialize in this field for more than 20 years.

2.

Almost 20 year export experience,

exported dozens of countries in Asia, Europe, Africa and America. All products are quite popular among clients.

3.

Specializing in plywood production line and finger joint board production line

. We have our own designers to meet any of your requirement.

4. Having own

after –sale maintenance cente

r, our engineer can go to overseas for installation and commissioning.

Why Choose Us

1. We Are Factory ( Not a Dealer )

We sell production machines designed together with clients, so it will be just and only for you, my dear. All machineries from Manufactory are made by ourselves, with lower price, good quality and assured full after service.

So please buy machine from factory.

2.We provide best service

Pre-sale services: enthusiasm and profession

We provide best service according to your demand, such as prophase plan, examine on the spot, process flow design , customized equipment, design solution for complete production lines and operator training etc.

In-sale services: be your assistant and servant

Send 2~12 technicians(adjustable according to the degree of automatic ) to the job site for guiding the installation and adjustment on duty, training operators and finishing the check and accept together with you. You can come to our factory to study for free.

After-sale services

We provide one year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replancements can be shipped to your right away.

To establish long term friendship, we will regularly pay return visit to customers.