Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

S-80kva

-

Coil Number:

-

Two Windings

-

Use:

-

Power Distribution Transmission

-

Coil Structure:

-

Toroidal

-

Rated Capacity:

-

80kva

-

Cooling Method:

-

Oil-immersed Type Transformer

-

Winding Type:

-

Multi-winding Transformer

-

Certification:

-

ISO9001-2000 ISO9001 CCC

-

Tapping Range:

-

±2X2.5% / ±5%

-

High Voltage:

-

35kv

-

Warranty:

-

2 Years

-

Power:

-

1000KVA

-

Rated Primary Voltage:

-

11

-

Rated Secondary Voltage:

-

0.415

Quick Details

-

Phase:

-

Three

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhongyi

-

Model Number:

-

S-80kva

-

Coil Number:

-

Two Windings

-

Use:

-

Power Distribution Transmission

-

Coil Structure:

-

Toroidal

-

Rated Capacity:

-

80kva

-

Cooling Method:

-

Oil-immersed Type Transformer

-

Winding Type:

-

Multi-winding Transformer

-

Certification:

-

ISO9001-2000 ISO9001 CCC

-

Tapping Range:

-

±2X2.5% / ±5%

-

High Voltage:

-

35kv

-

Warranty:

-

2 Years

-

Power:

-

1000KVA

-

Rated Primary Voltage:

-

11

-

Rated Secondary Voltage:

-

0.415

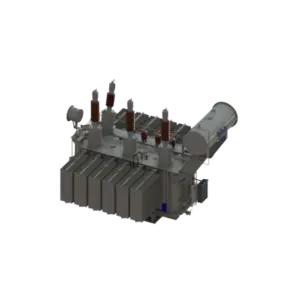

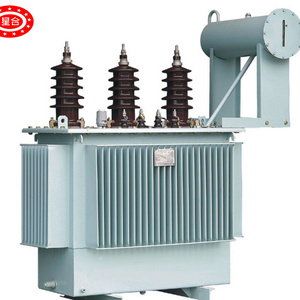

| Product Features | |

| Origin | Hebei, China |

| Rated Capacity | 1000kVA |

| Usage | Power Transformer, Distribution Transformer |

| Cooling Method | Oil-immersed Type Transformer |

| HS Code | 8504210000 |

| Tapping Range | ±2X2.5% / ±5% |

| High Voltage | 35kv |

| Trademark | ZHONGYI |

| Winding Type | Multi-winding Transformer |

| Certification | ISO9001-2000, ISO9001, CCC |

| Low Voltage | 0.4kv |

| Shape of Core | Ring |

| Vector Group | Dyn11, Yyn0 |

| Model NO. | S11-M |

| Transport Package | Wooden Case / According Customers' Demands |

| Application | Power, Electronic, Rectifier |

| Core | Core-type Transformer |

| S11-M-315~3150/10 Distribution Transformer Performance Parameters | ||||||||

|

Rated Capacity

kVA |

Voltage combination and tap range | Vector Group | Load loss kW | load loss kW(75C) | No-load current% | Short circuit impedance% | ||

|

high voltage

kV |

High voltage tapping range | Low voltage kV | ||||||

| 315 |

6

6.3 10 10.5 |

±5

±2×2.5% |

0.4 |

Dyn11

Yyn0 |

0.48 | 3.83 | 0.90 | 4.0 |

| 400 | 0.57 | 4.52 | 0.80 | |||||

| 500 | 0.68 | 5.41 | 0.80 | |||||

| 630 | 0.81 | 6.20 | 0.60 | 4.5 | ||||

| 800 | 0.98 | 7.50 | 0.60 | |||||

| 1000 | 1.15 | 10.30 | 0.60 | |||||

| 1250 | 1.36 | 12.00 | 0.50 | |||||

| 1600 | 1.64 | 14.50 | 0.50 | |||||

| 2000 | 1.94 | 18.30 | 0.40 | 5.0 | ||||

| 2500 | 2.29 | 21.20 | 0.40 | |||||

| 3150 | 2.81 | 26.66 | 0.40 | |||||

PRODUCTS FEATURES

1. 7-stage temperature control technology system, which combined with the temperature field dinite element analysis, to ensure full play to the performance advantages of various insulation materials.

2. The insulation system is based on DuPont Nomex ® Insulation paper technology.

3. Low noise: Unique noise reduction measures are adopted in different parts to ensure that the noise control is better than the national standards.

4. Low loss: The core is made of high-quality cold-rolled silicon steel sheet with high magnetic conductivity, using the Swiss core automatic laminating machine or longitudinal and transverse shearing, multi-stage full-slant seam automatic laminating, core tying using overall pressure and PET tape tying process, effectively reducing the no-load loss and no-load current of the transformer.

5. No leakage: The oil tank and oil storage cabinet have been tested for positive and negative pressure to ensure that there will be no oil leakage during normal operation. The components are installed with a flange groove structure, and all seals are made of high-quality once-formed acrylate rubber parts to prevent il-leakage.

6. Strong short circuit resistance: The transformer coils are calculated with reasonable ampere-turn balance and semi-rigid copper wire is used. The core claiming parts are calculated for strength and stiffness to meet the safety requirements of maximum short-circuit mechanical force. The winding pads are all densified and made of high-density rigid cardboard and adopted integra set & integral pressing to ensure the accuracy of assembly and the short-circuit resistance.

STANDARDS

S13-M series oil-immersed power transformers have passed the test of the National Transformer Quality Supervision and Inspection Center, and all indicators have reached the advanced level of domestic and international products. The performance indicators meet the energy efficiency requirements of GB20052-2020 and also won the 3C, PCCC energy-saving certification, ISO-9001, ISO-45001, and ISO-14001 certificates.

USE & INSTALLATION

SERVICE CONDITIONS - The installation site shall not be flooded by water, the altitude shall not exceed 1000m, and the ambient temperature shall not be higher than 40ºC. The relative humidity is 100%, and the environment is 40ºC to -25ºC (-25ºC requires an on-load tap changer and temperature controller).

PACKAGING & TRANSPORTATION - The products can be partially disassembled and transported (such as on-load tap changer, temperature controller, air cooling device, enclosure, etc. can be packaged separately) or packed as one piece in packaging boxes for transportation.

VISUAL INSPECTION BEFORE INSTALLATION - After opening the package, remove the protective device and check the external conditions, especially paying attention to the mechanical integrity of the coil and iron core, and the bolt fastening at the connection.

INSPECTION BEFORE OPERATION - Measure the DC resistance of high voltage and low voltage windings. Then check the grounding of the iron core to see whether the grounding is reliable and whether foreign matters are overlapping. Last to test the insulation resistance.

ENERGIZING - Before putting into operation, the transformer shall be put into trial operation under no-load, and the protection system shall be checked and adjusted after 3 times of impulse closing.