- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TAI XIANG

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2550*1880*730mm

-

Weight (KG):

-

5000 KG

-

Machine type:

-

Semi-automatic Blowing Machine

-

Cavity:

-

1cavity

-

Prodcution output:

-

80-150pcs/hour

-

Key words:

-

semi auto blowing machine

-

Color:

-

customized

-

Product name:

-

semi auto bottle blowing machine

-

Name:

-

20L bottle blowing moulding machine

-

machine size:

-

2550*1880*730mm

-

machine weight:

-

1500kgs

-

heater size:

-

2650*1600*640mm

Quick Details

-

Neck Diameter(mm):

-

45 mm

-

Max.Bottle Diameter(mm):

-

5000 mm

-

Max.Bottle Height(mm):

-

5000 mm

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TAI XIANG

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2550*1880*730mm

-

Weight (KG):

-

5000 KG

-

Machine type:

-

Semi-automatic Blowing Machine

-

Cavity:

-

1cavity

-

Prodcution output:

-

80-150pcs/hour

-

Key words:

-

semi auto blowing machine

-

Color:

-

customized

-

Product name:

-

semi auto bottle blowing machine

-

Name:

-

20L bottle blowing moulding machine

-

machine size:

-

2550*1880*730mm

-

machine weight:

-

1500kgs

-

heater size:

-

2650*1600*640mm

Company profile

TX series plastic bottle blowing ma chine produced by Taixiang plastic co.,ltd is a high efficiency, high precision, practical, reliable and stable two-step half/full automatic blowing machine equipment.

The pneumatic components and electrical components of the plastic machine adopt domestic famous products,D - type high - configuration pneumatic components and electrical components are manufactured by German, Japanese, Korean and other brand enterprise products.The control system is based on common circuit, domestic computer and PLC program control,designed for easy maintenance, simple operation, safe and reliable, beautiful and durable,it will ensure the smooth development of your production and the prosperity of the enterprise.

The machine should be equipped with the thermoplastic hollow molding equipment, namely the two-step plastic bottle blowing machine.Products need to be made by injection molding machine bottle embryo, wait for after cooling the form a complete set of machine dedicated heater preheating, make it feel after in elastic state under the machine made into hollow container.There are two kinds of ordinary honeycomb tube aluminum oven and far infrared rotary heater. According to the actual situation of the customer to deploy,the machine type hyperbolic arm locking mould is adopted to ensure that there is no expansion mode under high pressure blowing.

This machine is suitable for the hollow forming of PET material with polyester blowing. It can also be applied to other thermoplastic bottle grade plastics, such as PETG, PC, PE, PP, PS, AS, TRITAN, etc.The current market is integrated with the modern domestic and foreign advanced transmission devices and automatic control technology.In product design and manufacture according to customer feedback, constantly update perfect, has the production speed, stable operation, small power consumption, small volume, low cost, long service life, safety maintenance, etc

.

Specifications

|

Category |

Item |

Unit |

LT1C 20 L |

|

Finished product |

material |

/ |

PET |

|

volume |

L |

20 L |

|

|

theoretical output |

P CS /h |

8 0- 150 |

|

|

maximum height |

MM |

60 0 |

|

|

the largest diameter |

MM |

35 0 |

|

|

Template size |

the largest acreage of template |

MM |

650 *600 |

|

maximum thickness of mold |

MM |

60 0 |

|

|

clamping force |

T |

25 |

|

|

mold opening stroke |

MM |

35 0 |

|

|

Auxiliary equipment |

air compressor |

15KW |

≥3.0/3.0 |

|

air freeze dryer |

3.0 M pa |

≥3.0/3.0 |

|

|

air precision filter |

3 .0 M pa |

≥3.0/3.0 |

|

|

Electric power of main engine |

power |

KW |

25 |

|

voltage / frequency(three - phase) |

V/HZ |

380/50-60 |

|

|

working pressure |

M pa |

0.8-1.2 |

|

|

blowing pressure |

M pa |

≤3.0 |

|

|

Size |

s ize of main engine |

MM |

2 26 0* 7 4 0* 1880* |

|

heater size |

MM |

26 6 0*6 5 0*1 60 0 |

|

|

Weight |

weight of main engine |

KG |

150 0 |

|

heater weight |

KG |

56 0 |

|

|

Note: as the company's equipment is constantly updated, the specific parameters shall be subject to the equipment! |

|||

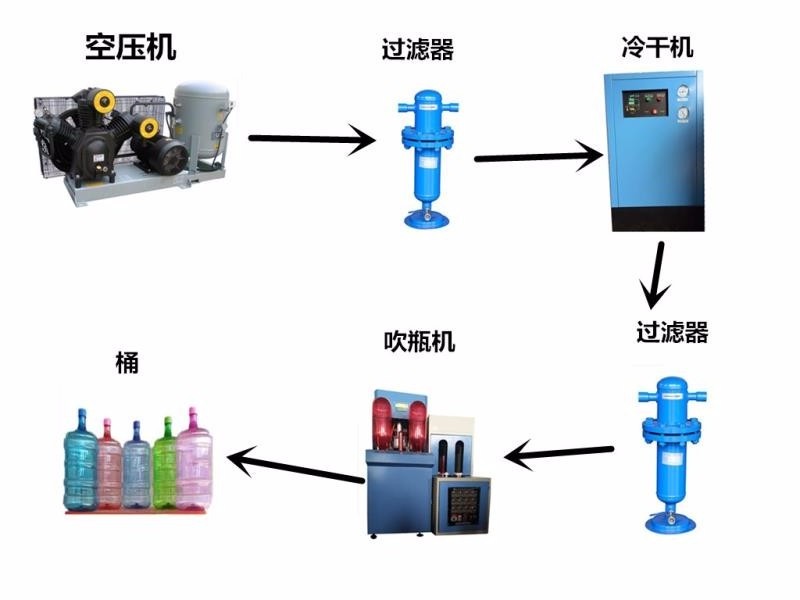

Process of blowing bottle

Main features

1) Adopt advanced microcomputer control system,stable performance;

2)The overall casting frame increases the firmness and stability of the machine;

3)It is heated by infrared lamp tube,with strong penetrating power,the bottle embryo rotates to heat,the orbit is heated evenly,fast and reliable;

4)The lamp tube,reflector width and height of the heating zone can be adjusted to suit the heating of the bottle embryo of different structure,and have the automatic exhaust temperature device to ensure the constant temperature of drying way;

5)Each mechanical action has a secure self -locking device that automatically switches to a secure state when a process fails;

6)Each action is driven by cylinder,no oil pump,no pollution,low noise;

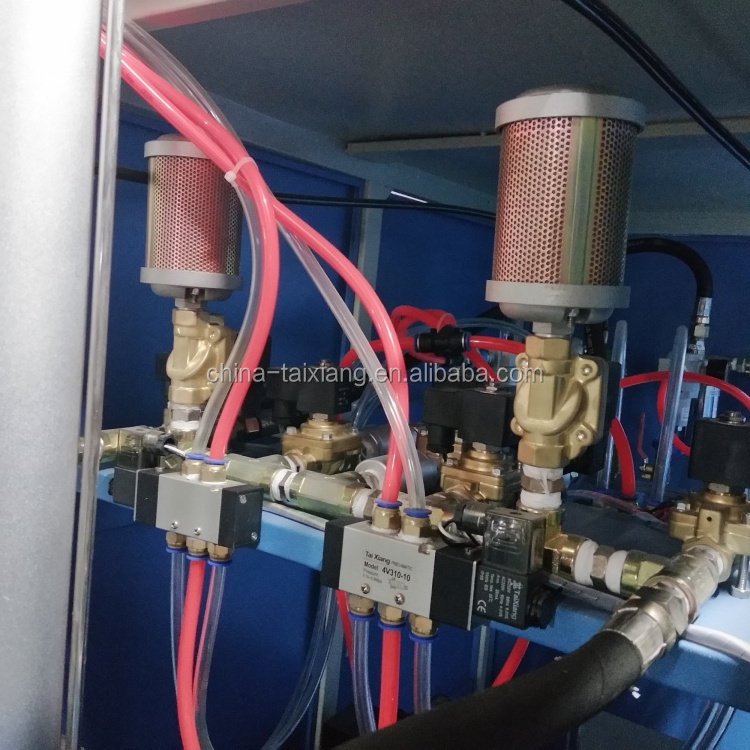

7)The gas circuit design divides the action and blow air into there parts to meet the demand of the different pressure of blowing bottle and action;

8)Use high pressure hyperbolic arm connecting rod to clamp,clamping force is strong;

9)The operation method is manual and automatic;

10)Safe and reliable unique valve position design makes the gas path clear;

11)The production process is fully automated and has advantages of investment saving,high efficiency,convenient operation,simple maintenance,safety;

12)The bottle body is free from pollution-specific function of one-way put the bottle embryo and one-way take the bottle, so that the two movements are crisp and the production volume is increased;

13)The cooling system achieves desired cooling effect;

14)The scrap rate was less than 0.2%.The anterior-posterior direction and left-right direction of the machine head(drawing cylinder)adopts parallel adjustment method,which is more convenient to stall the mold.

Product show

Workshop and office

Customer

How to contact us