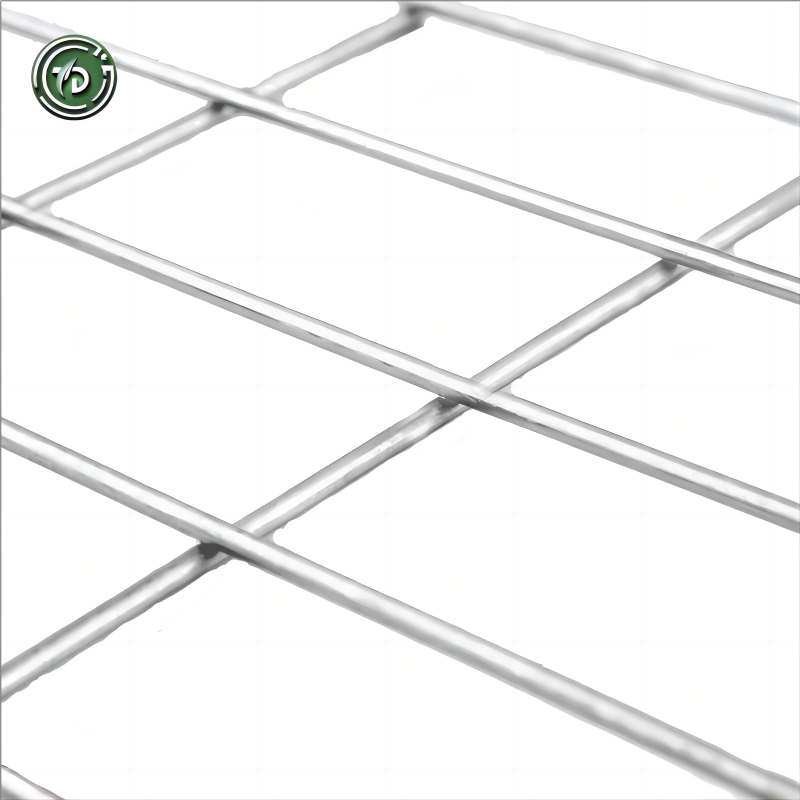

High quality raw materials can improve the strength and durability of welded wire mesh.

Tiedi Metal chooses high quality low carbon steel wire, which are very strong and toughness. Each batch of TIEDI raw materials is subject to tensile strength test, which ensures that our products maintain the high level in the metal materials industry.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TIEDI

-

Model Number:

-

TD-WP10017

-

Wire Gauge:

-

1.6mm-6mm, Bwg1-Bwg16

-

Surface treatment:

-

Hot Dipped Galvanzied or Electro Galvanized

-

Product Name:

-

Welded Wire Mesh Panel

-

Opening:

-

10x10,15x15,20x20,30x30,40x40,50x50,55x55,60x60mm

-

Hole Size:

-

1/2" - 6''

-

Other Type:

-

Pvc Coated Panel,Stainless Steel Panel

-

Keyword:

-

Welded Panel

-

Feature:

-

Easily Assembled, Anti-Corrosion, Eco Friendly, Durable

-

Panel Size:

-

1x2m, 1.22x2.44, Customized

-

Welding Type:

-

Galvanized After Welding

Quick Details

-

Material:

-

Low-Carbon Iron Wire

-

Type:

-

Welded Mesh

-

Application:

-

Fence Mesh, Gabions,Cages,Construction Wire Mesh

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TIEDI

-

Model Number:

-

TD-WP10017

-

Wire Gauge:

-

1.6mm-6mm, Bwg1-Bwg16

-

Surface treatment:

-

Hot Dipped Galvanzied or Electro Galvanized

-

Product Name:

-

Welded Wire Mesh Panel

-

Opening:

-

10x10,15x15,20x20,30x30,40x40,50x50,55x55,60x60mm

-

Hole Size:

-

1/2" - 6''

-

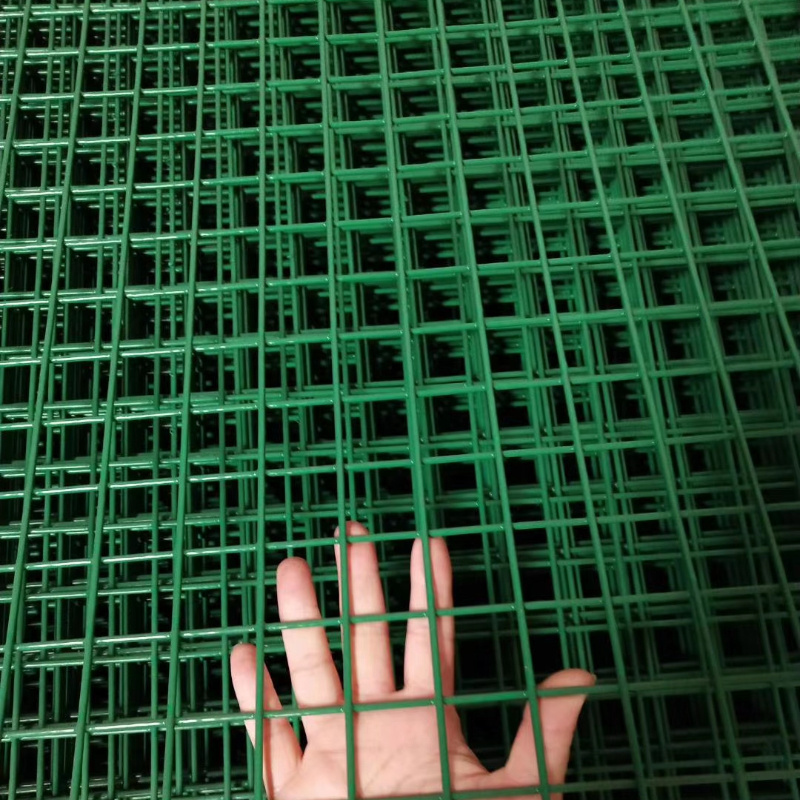

Other Type:

-

Pvc Coated Panel,Stainless Steel Panel

-

Keyword:

-

Welded Panel

-

Feature:

-

Easily Assembled, Anti-Corrosion, Eco Friendly, Durable

-

Panel Size:

-

1x2m, 1.22x2.44, Customized

-

Welding Type:

-

Galvanized After Welding

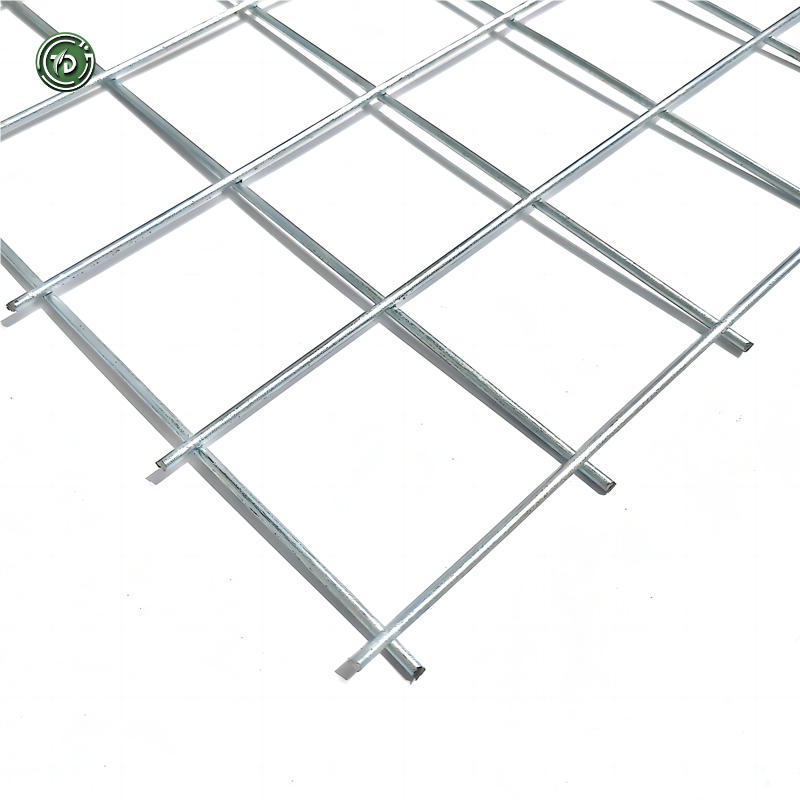

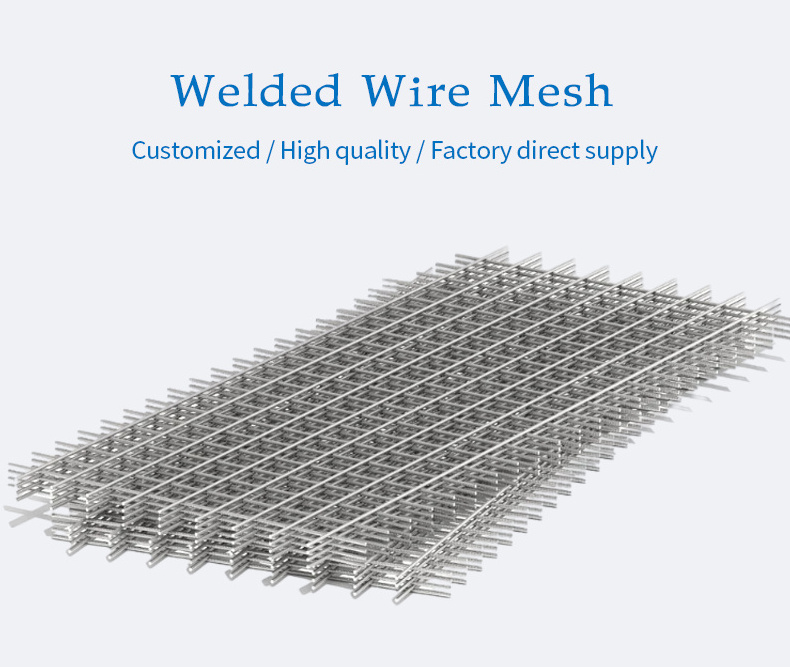

Welded Wire Mesh Panel

As all know, Welded wire mesh panel is a mesh made of high-quality low-carbon steel wire that has been straightened and cut and then welded by electric welding equipment. Panel has thicker wire diameter and larger opening sizes. The welded wire mesh can be divided into

welded mesh rolls

and

welded wire mesh panels

.

Product Show

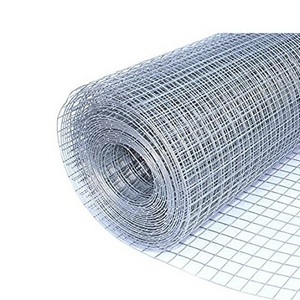

Galvanized Welded Wire Mesh Panel

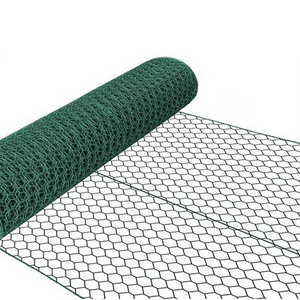

Pvc Coated Welded Wire Mesh Panel

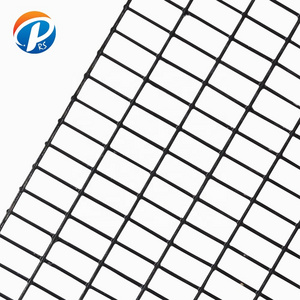

Black Welded Wire Mesh Panel

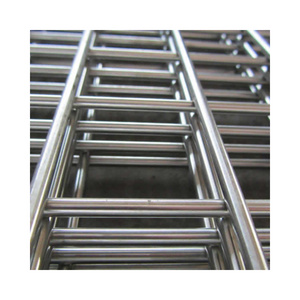

Construction Welded Wire Mesh Panel

Surface Treatment Comparison

|

Type

|

|

Electro-Galvanized After Welded

|

Electro-Galvanized After Welded

|

Hot Dipped Galvanized After Welded

|

||

|

Zinc

|

|

20-30g/Sqm

|

|

Over 200g/Sqm

|

||

|

Price

|

|

Low

|

|

High

|

||

|

Performance

|

|

Middle

|

|

Best

|

||

Product Specifications

|

Welded Wire Mesh Panel

|

|

|

|

|

||||

|

Size(mm)

|

Wire Diameter(mm)

|

|

Wire Diameter(mm)

|

|

||||

|

15x15

|

1.6-2.7mm

|

|

BWG16-12

|

|

||||

|

20x20

|

1.6-3.5mm

|

|

BWG16-9

|

|

||||

|

22x22

|

1.6-3.5mm

|

|

BWG16-9

|

|

||||

|

25x25

|

1.6-4.5mm

|

|

BWG16-7

|

|

||||

|

30x30

|

1.6-4.5mm

|

|

BWG16-7

|

|

||||

|

35x35

|

2.0-3.7mm

|

|

BWG14-9

|

|

||||

|

40x40

|

1.8-4.5mm

|

|

BWG15-7

|

|

||||

|

45x45

|

2.0-3.5mm

|

|

BWG14-9

|

|

||||

|

50x50

|

2.0-5.0mm

|

|

BWG14-5

|

|

||||

|

55x55

|

2.0-5.8mm

|

|

BWG14-4

|

|

||||

|

60x60

|

2.0-7.8mm

|

|

BWG14-1

|

|

||||

|

70x70

|

2.2-5.8mm

|

|

BWG13-4

|

|

||||

|

80x80

|

2.2-5.8mm

|

|

BWG13-4

|

|

||||

|

110x110

|

2.2-7.8mm

|

|

BWG13-1

|

|

||||

|

Material: High Quality Low-Carbon Iron Wire

|

|

|

|

|

||||

|

|

|

|

||||||

Product Advantages

High quality raw materials

Advanced equipment

Tiedi Metal uses the

specially improved

welding machines to ensure opening uniform, welding firmness and flatness. And it not only can improve production efficiency to ensure delivery time of your order, but also reduce production cost to enhance your

market competitiveness.

Precise control of welding parameters

During the welding process, strictly control welding parameters such as welding current, voltage, speed, pressure, etc.

Ensure weld quality and consistency for each solder joint, avoiding defects or fluctuations in quality.

And evaluate the strength and reliability of the product through methods such as tensile test, bending test and fracture test.

Regular maintenance of electrodes

We choose appropriate electrodes with good conductivity, thermal conductivity, wear resistance, and stability, and regularly sand down the notches or grooves generated during work.

This can improve welding quality, reduce welding defects, and improve production efficiency.

Increase employee training

Train production workers to ensure they possess competent operational skills and quality awareness, Deal with the problems

or defects found in a timely manner.

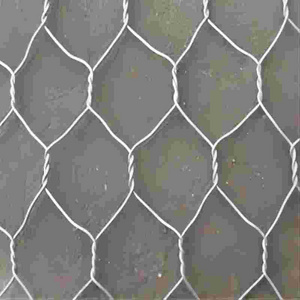

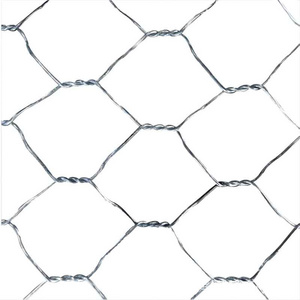

Applications

Welded wire mesh panels are used extensively in garden fencing, prison fencing, factory fencing animal fencing, and other site security fencing, decorative mesh, plaster mesh.

Packing&Shipping

Packing

Moisture resistance paper, Stretch plastic film, Shrink plastic film, In bulk or on pallets or in wooden box.

Shipping

We will look for a professional transportation agent to deliver the products, so we are capable of delivery products to

most ports all over the world.

Hot Searches