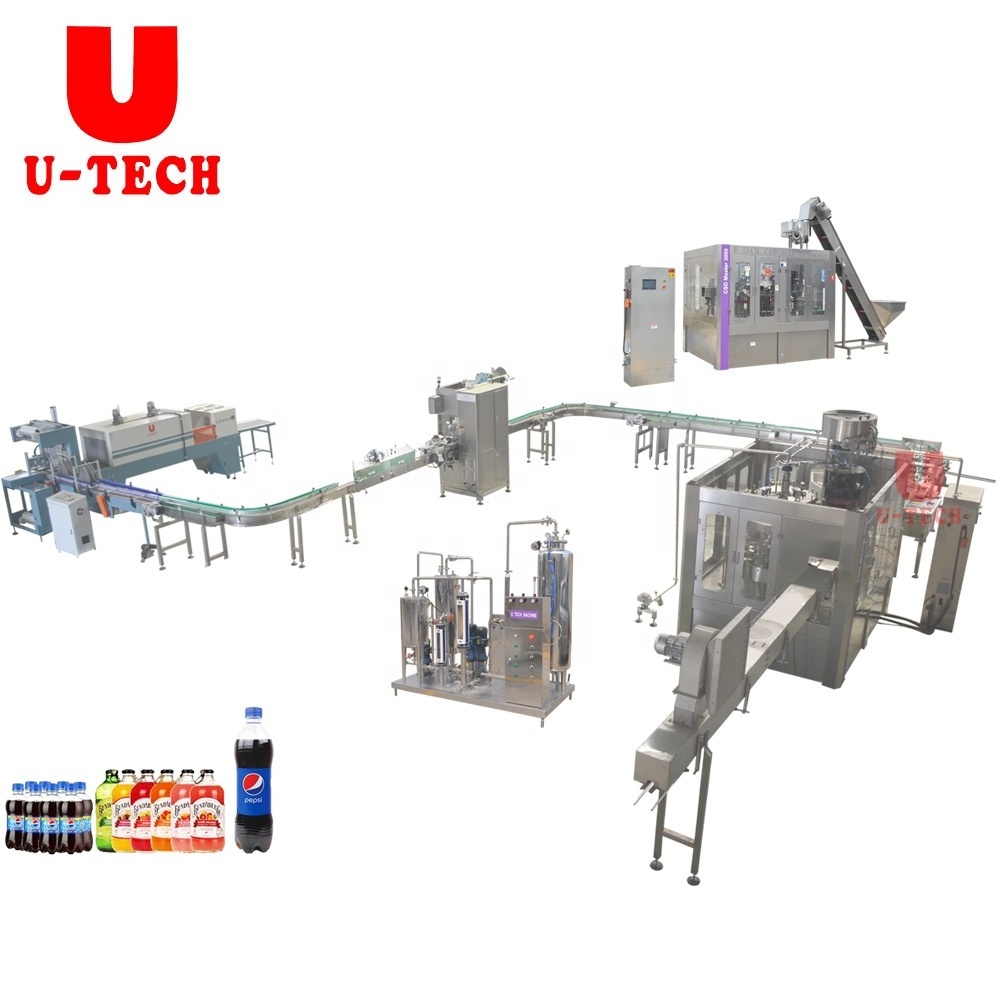

Products Introduction:

1. The Advanced Carbonated Beverage Filling Machine / Soda Water Filling Equipment is mainly used for filling soft drink. It combines washing and filling and capping as one automatic body suitable for PET or other plastic bottles. The equal pressure filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others.

2. Besides using photo-electronic detectors to detect the running of every important sub-process, it employs PLC from OMRON for automatic control of the whole process and new type air-channel for bottle-loading featuring speediness and damage-free of bottle.

3. The handing-over of bottles between two linking structures is fulfilled by applying clamping-bottle-neck method.

4. For bottle of different shape only a few parts need to be changed and the substituting is simple, which shows the machine is of good adaptability.

5. High automation and easy operation make it an ideal option for beverage companies.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

380V / 220V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U TECH

-

Dimension(L*W*H):

-

2400x1650x2500mm

-

Weight:

-

2500 KG

-

Processing Types:

-

Carbonted drink

-

Usage:

-

water filling and packing etc

-

Function:

-

3 in 1 washing, filling capping

-

Bottle type:

-

PET, Glass, Plastic

-

Production capacity:

-

7000BPH

-

Bottle size:

-

200ML-2000ML

-

Diameter:

-

50-108mm

-

Height:

-

60-220MM

-

Capacity:

-

6000bph

-

Filling material:

-

Gas Liquid

Quick Details

-

Machinery Capacity:

-

6000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Water, Juice

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

380V / 220V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U TECH

-

Dimension(L*W*H):

-

2400x1650x2500mm

-

Weight:

-

2500 KG

-

Processing Types:

-

Carbonted drink

-

Usage:

-

water filling and packing etc

-

Function:

-

3 in 1 washing, filling capping

-

Bottle type:

-

PET, Glass, Plastic

-

Production capacity:

-

7000BPH

-

Bottle size:

-

200ML-2000ML

-

Diameter:

-

50-108mm

-

Height:

-

60-220MM

-

Capacity:

-

6000bph

-

Filling material:

-

Gas Liquid

Product Introduction

Technical parameter

|

Model

|

DCGF8-8-3

|

DCGF12-12-6

|

DCGF18-18-6

|

DCGF 24-24-8

|

||

|

washing, filling and capping heads No.

|

8-8-3

|

12-12-6

|

18-18-6

|

24-24-8

|

||

|

Capacity

|

1500~2000BPH

|

3000~3500BPH

|

4000~5000BPH

|

6000~8000BPH

|

||

|

Bottle Volume Range

|

volume=330-2000ml

|

φ=50-110 H=150~340mm volume=330-2500ml

|

|

|

||

|

Motor power(kw)

|

Main motor 1.9KW

|

Main motor 3.5kw

|

Main motor 4.0kw

|

Main motor 4.8kw

|

||

|

Overall dimensions (mm)

|

1900*1420*2000

|

2450*1800*2400

|

2650*1900*2400

|

2900*2100 *2400

|

||

|

Weight (kg)

|

|

2500

|

3500

|

4500

|

||

|

Model

|

DCGF 32-32-8

|

DCGF 40-40-10

|

DCGF 50-50-12

|

DCGF 60-60-15

|

||

|

washing, filling and capping heads No.

|

32-32-8

|

40-40-10

|

50-50-12

|

60-60-15

|

||

|

Capacity

|

8000-10000BPH

|

10000-12000BPH

|

12000-15000BPH

|

15000-18000BPH

|

||

|

Bottle Volume Range

|

volume=330-2000ml

|

φ=50-110 H=150 ~340mm volume=330-2500ml

|

|

|

||

|

Motor power(kw)

|

Main motor 7.6kw

|

Main motor 8.3kw

|

Main motor 9.6kw

|

Main motor 15Kw

|

||

|

Overall dimensions (mm)

|

4100*2000 *2400

|

4550*2650 *2400

|

5450*3210 *2400

|

5500*3510 *2400

|

||

|

Weight (kg)

|

6500

|

8500

|

9800

|

12000

|

||

Details Images

Bottle Inlet (Air Conveyor)

All Stainless Steel 304 include the all the connection parts and bottle exchange part .

Big motor Air fan Steady running for the machine . Strong Machine . Can be customizer the length and design .

Big motor Air fan Steady running for the machine . Strong Machine . Can be customizer the length and design .

Out Look

> 304 stainless steel frame

> Tempering Glass window, Clear & no odor

> Excellent start wheel design, easy change over parts

> Machine Base with anti-rust process, ensure the forever antirust

> All seal where liquid may Leakage & base neck come with rubber, water proof

> Manual lubrication system

> Tempering Glass window, Clear & no odor

> Excellent start wheel design, easy change over parts

> Machine Base with anti-rust process, ensure the forever antirust

> All seal where liquid may Leakage & base neck come with rubber, water proof

> Manual lubrication system

Washing Station

➢ All 304 stainless steel rinser heads, water spray style inject design, more save water consumption & more clean

➢ 304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

➢ 304 stainless steel washing pumps

➢ 304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

➢ 304 stainless steel washing pumps

Filling Station

➢ High precision filling nozzle, PLC variable signal control, ensure high filling precision & filling smoothly & steadily,

➢ All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean

➢ No bottle no filling

➢ All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean

➢ No bottle no filling

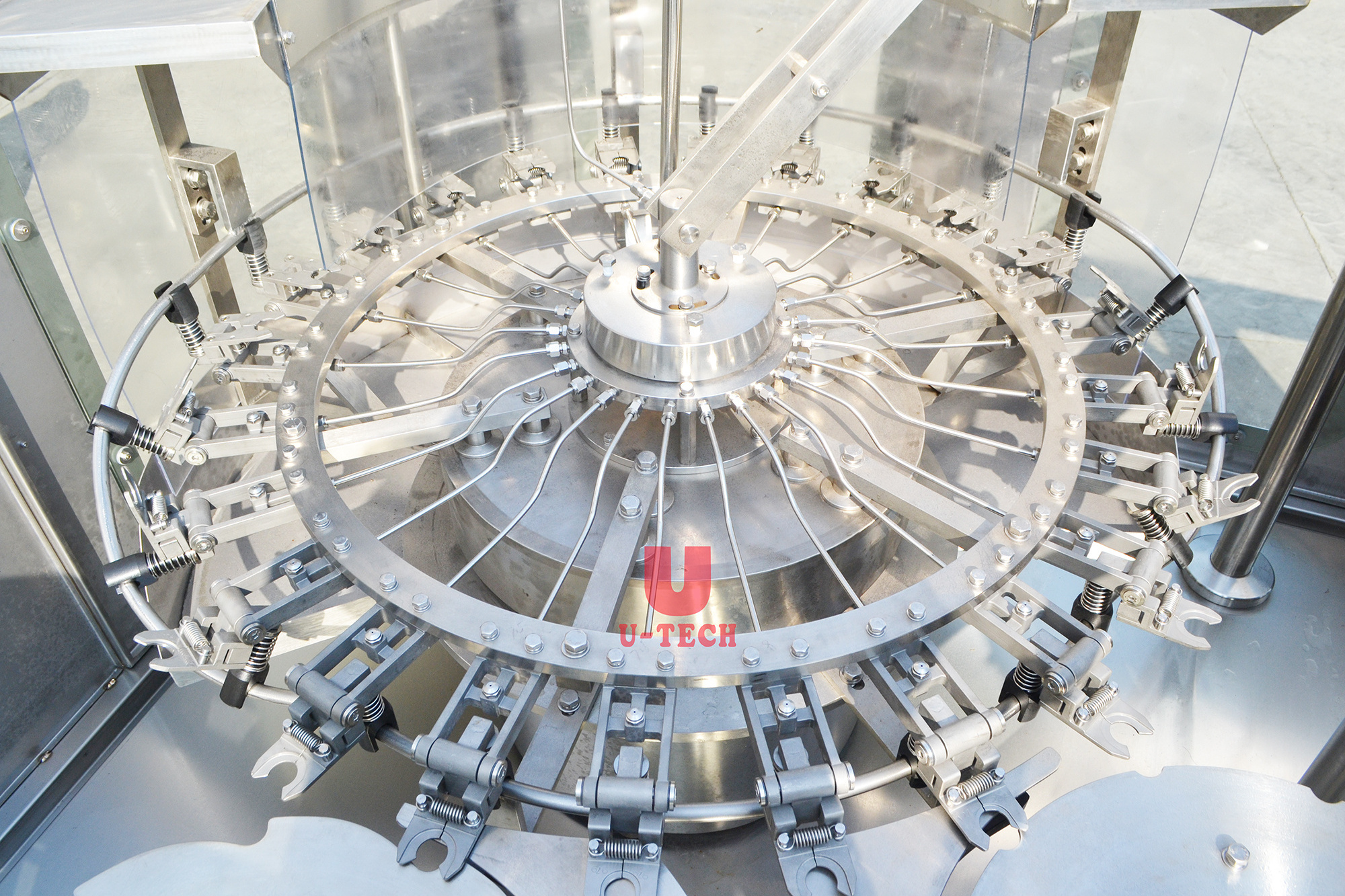

Capper Station

➢ Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

➢ All 304stainless steel construction

➢ No bottle no capping

➢ All 304stainless steel construction

➢ No bottle no capping

Safe Device & World Famous Electrical Configuration

Bottle Exchange Parts For Each Bottle Type

Production Flow Chart

Free 2D & 3D Bottle Design

Our Machine can fit bottle size from 100ml ~ 2000ml Bottle / 3L ~10L Bottle 10~25L Bottle And three size of bottle fitting parts for free .

Free Layout Plant Design

Every Factory are different and unique , We will special design the layout according to your factory , supply the best beverage package solution for you

Free Layout Plant Design

Every Factory are different and unique , We will special design the layout according to your factory , supply the best beverage package solution for you

Free Spare Parts

All Reliable Machine will be supply Two year Spare parts for Free . High Quality Parts ensure the stable of machine's running .

Different Liquid Filling Machine

Automatic 3 in 1 carbonated soft drink filling machine plant

In Uzbekistan

Suitable :

Carbonated Drink,etc.

Bottle Material :

PET/Metal

Bottle Type : Round / Square / Unique

Cap : Screw cap

Label : Sticker Label / Shrink Label

Bottle Type : Round / Square / Unique

Cap : Screw cap

Label : Sticker Label / Shrink Label

Can Filling Line In Mexico

Suitable :

Carbonated Drink,etc.

Bottle Material :

Metal

Bottle Type : Round

Cap : Sealing cap

Label : Printing Label / Shrink Label

Bottle Type : Round

Cap : Sealing cap

Label : Printing Label / Shrink Label

Beverage Mixer

The mixer is mainly suitable for mixing process of all kinds of carbonated drinks.

Auto Bottle Blowing Machine

<1>New Auto Preform Unscrambler System<2>Perfect heating system design decrease power consumption.

<3>Special oven design helps power-saving and easy maintain.

<3>Special oven design helps power-saving and easy maintain.

Bottle Warming Machine

This machine can increase the temperature of cold filling carbonated drinks to 36℃-40℃

Double Station Shrink Sleeve Labeling Machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine

About U TECH

Certifications

FAQ

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Hot Searches