- Product Details

- {{item.text}}

Quick Details

-

Specification:

-

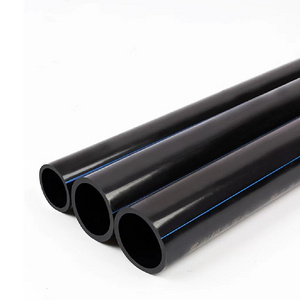

DN 16mm-1400mm, use for water supply

-

Length:

-

6mm-12mm as demand

-

Thickness:

-

2.3mm-102.9mm

-

Standard:

-

ISO,EN

-

Colr:

-

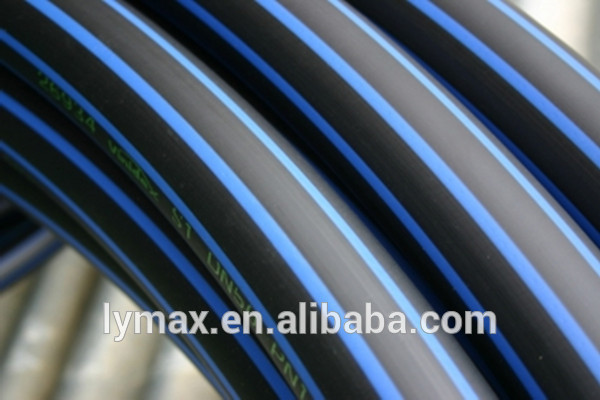

black with blue stripe

-

Connection:

-

flanged joint, butt fusion,socket fusion

-

Service life:

-

More than 50 years under normal condition

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MAX

-

Model Number:

-

HDPE pipe for water supply

-

Specification:

-

DN 16mm-1400mm, use for water supply

-

Length:

-

6mm-12mm as demand

-

Thickness:

-

2.3mm-102.9mm

-

Standard:

-

ISO,EN

-

Colr:

-

black with blue stripe

-

Connection:

-

flanged joint, butt fusion,socket fusion

-

Service life:

-

More than 50 years under normal condition

High density polythene HDPE poly coiled tubing/pipes

Advantages of Coiled Tubing:

6.Recycled and Environment-friendly

Properties of

Coiled Tubing:

1.Specific Gravity, g/cm3, 20(C): 0.941-0.965

2.Longitudinal Reversion, % (110(C)): <=3

3.Oxidation Induction Time, min (200(C)): >=20

4.Extension Rate at Break. %: >=350

5.Hydraulic Pressure Test:

1)20(C), Hoop Stress is 12.4 Mpa, 100h: No Failure.

2)80(C), Hoop Stress is 5.5Mpa, 165h: No Failure.

3)80(C), Hoop Stress is 5.0Mpa, 1000h: No Failure

Specification of

Coiled Tubing:

| PE100 Water Pipe | |||||

| Standard:GB/T13663-2000 | Thickness: mm | ||||

| PN | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa |

| SDR | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 |

| DN | Thickness | Thickness | Thickness | Thickness | Thickness |

| 16 | 2.0 | ||||

| 20 | 2.0 | 2.3 | |||

| 25 | 2.3 | 3.0 | |||

| 32 | 2.3 | 2.4 | 3.0 | ||

| 40 | 2.3 | 2.3 | 3.0 | 3.7 | |

| 50 | 2.3 | 2.9 | 3.7 | 4.6 | |

| 63 | 2.3 | 2.5 | 3.6 | 4.7 | 5.8 |

| 75 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 |

| 90 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 |

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

| 125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 |

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

| 630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.3 |

| 710 | 27.2 | 33.9 | 42.1 | 52.2 | - |

| 800 | 30.6 | 38.1 | 47.4 | 58.8 | - |

| 900 | 34.4 | 42.9 | 53.3 | ||

| 1000 | 38.2 | 47.7 | 59.3 | ||

| 1200 | 45.9 | 57.2 | 70.6 | ||

| 1400 | 53.9 | 66.7 | 82.4 | ||

Applications of

Coiled Tubing:

1.City water pipe network system.

2.Urban and rural drinking water pipeline .

3.Chemical industry, chemical fiber, food, forestry, printing and dyeing, pharmaceutical. light industry, paper-making, metallurgy Industrial pipeline.

4.Agricultural irrigation pipe.

Connect Way:

HDPE Pipe Fittings:

Packaging and shipping:

Our Service:

1. 24 hours in time response.

2. 7 years professional manufacturer experience.

3. ISO9001 & GB/T 13663-2000 Standard product quality.

4. Best after-sales service.

5. One year warrenty.