- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Building, Core Materials etc

-

Design Style:

-

Industrial

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

FORE

-

Model Number:

-

XPS Foam

-

Type:

-

XPS Boards

-

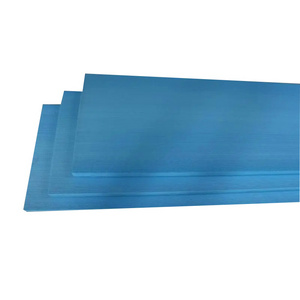

Color:

-

Red, Beige, Green, Blue, White

-

Thickness:

-

6 - 100mm

-

Max Width:

-

1200mm

-

Length:

-

Customized

-

Thermal Conductivity:

-

≤0.03

-

Compressive strength:

-

150 - 500KPa

-

Density:

-

33-45kg/m3

-

Water absorption:

-

≤1%

-

Surface:

-

Smooth, Rough, Grooved

-

Product name:

-

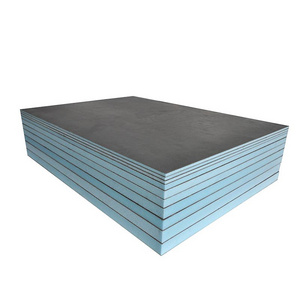

High Density Insulation Extruded Polystyrene XPS Styrofoam Sheets

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

Cross Categories Consolidation

-

Application:

-

Building, Core Materials etc

-

Design Style:

-

Industrial

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

FORE

-

Model Number:

-

XPS Foam

-

Type:

-

XPS Boards

-

Color:

-

Red, Beige, Green, Blue, White

-

Thickness:

-

6 - 100mm

-

Max Width:

-

1200mm

-

Length:

-

Customized

-

Thermal Conductivity:

-

≤0.03

-

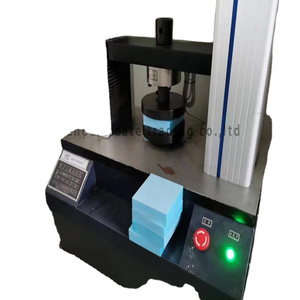

Compressive strength:

-

150 - 500KPa

-

Density:

-

33-45kg/m3

-

Water absorption:

-

≤1%

-

Surface:

-

Smooth, Rough, Grooved

-

Product name:

-

High Density Insulation Extruded Polystyrene XPS Styrofoam Sheets

XPS Foam Board Introduction

Extruded Polystyrene (XPS) Foam Insulation Board

is a kind of rigid extruded polystyrene thermal insulation material, based on polystyrene resin as main ingredient, by adding certain proportional additive, is a kind of high performance rigid foam with honeycomb closed pore structure which manufactured through special heating extrusion forming process under the condition of strict quality control on imported production line, the interconnection wall of honeycomb structure has consistent thickness, and there will be no gap completely, therefore, the uniform organization through extrusion process makes the products have excellent thermal insulation properties, good wet moisture resistance and high pressure performance.

XPS Foam Board Features

>> Excellent thermal insulation

>> High strength compressive strength

>> Superior moisture resistance

>> Anti-corrosion durable

>> High-quality environmental protection

Why choose our XPS

>> Material: Virgin GPPS material

>> ECO Flame Retardant: Methyl Octabromo Ether and Brominated SBS

>> Vesicant: Co

2

+Alcohol

|

Items

|

Unit

|

Performance

|

|

|

|

|

|

|

||||||

|

Compression Strength

|

Kpa

|

≥150

|

≥200

|

≥250

|

≥300

|

≥350

|

≥400

|

≥450

|

||||||

|

Water Absorption

|

%(v/v)

|

≤1.5

|

|

≤1.0

|

|

|

|

|

||||||

|

Water Vapour Permeability

|

ng/(m.s.pa)

|

≤3.5

|

|

≤3.0

|

|

|

≤2.0

|

|

||||||

|

Thermal Conductivity 10℃

|

w/(m.k)

|

≤0.028

|

|

|

|

|

≤0.027

|

|

||||||

|

Thermal Conductivity 25℃

|

w/(m.k)

|

≤0.030

|

|

|

|

|

≤0.029

|

|

||||||

|

Dimensional Stability

|

%

|

≤2.0

|

|

≤1.5

|

|

|

≤1.0

|

|

||||||

|

Fire Retardant

|

/

|

B1/B2/B3

|

|

|

|

|

|

|

||||||

|

Operating Temperature

|

℃

|

-50℃~70℃

|

|

|

|

|

|

|

||||||

|

Max Wdith

|

mm

|

1200mm

|

|

|

|

|

|

|

||||||

|

Thickness

|

mm

|

8~100mm

|

|

|

|

|

|

|

||||||

|

Density

|

kg/m

3

|

32~42

|

|

|

|

|

|

|

||||||

|

Package

|

Plastic bags

|

|

|

|||

|

|

Plywood pallet

|

|

|

|||

|

|

According to customers requirements

|

|

|

|||

|

Delivery

|

Samples: 2- 3 days

|

|

|

|||

|

|

Mass production: 10-15 days

|

|

|

|||

|

High Density Insulation Extruded Polystyrene XPS Styrofoam Sheets

|

|

|

|

|||

>> Wall Insulation

>> Roof insulation

>> Floor Insualtion

>> Cold storage project

>> Refrigerated truck body

>> Other: surfboard and electronic whiteboard etc.