- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

70-82

-

CrO Content (%):

-

70-82

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Liaoning, China

-

Model Number:

-

ZTM-ZTH12

-

Brand Name:

-

ZTM

-

Name:

-

Magnesia carbon bricks

-

Bulk density ≥(g/cm):

-

2.90

-

Cold crushing strength ≥(Mpa):

-

35

-

Apparent porosity ≤(%):

-

6

-

Modulus of rupture (1400℃x0.5h) ≥(Mpa):

-

6

-

Size:

-

Customizable

-

Certificate:

-

ISO9001:2008

Quick Details

-

SiO2 Content (%):

-

0

-

Al2O3 Content (%):

-

70%

-

MgO Content (%):

-

70-82

-

CaO Content (%):

-

70-82

-

CrO Content (%):

-

70-82

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Liaoning, China

-

Model Number:

-

ZTM-ZTH12

-

Brand Name:

-

ZTM

-

Name:

-

Magnesia carbon bricks

-

Bulk density ≥(g/cm):

-

2.90

-

Cold crushing strength ≥(Mpa):

-

35

-

Apparent porosity ≤(%):

-

6

-

Modulus of rupture (1400℃x0.5h) ≥(Mpa):

-

6

-

Size:

-

Customizable

-

Certificate:

-

ISO9001:2008

Magnesite Carbon Brick

MgO-C Brick

Magnesia Carbon Refractory Bricks for EAF BOF Ladle

Products Description

Magnesia Carbon brick Introduction

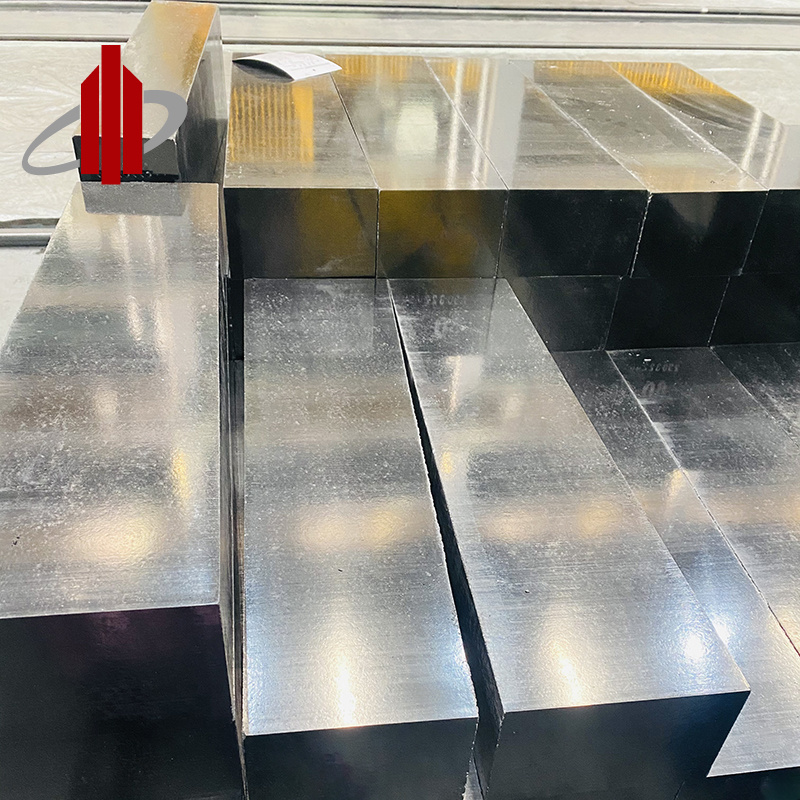

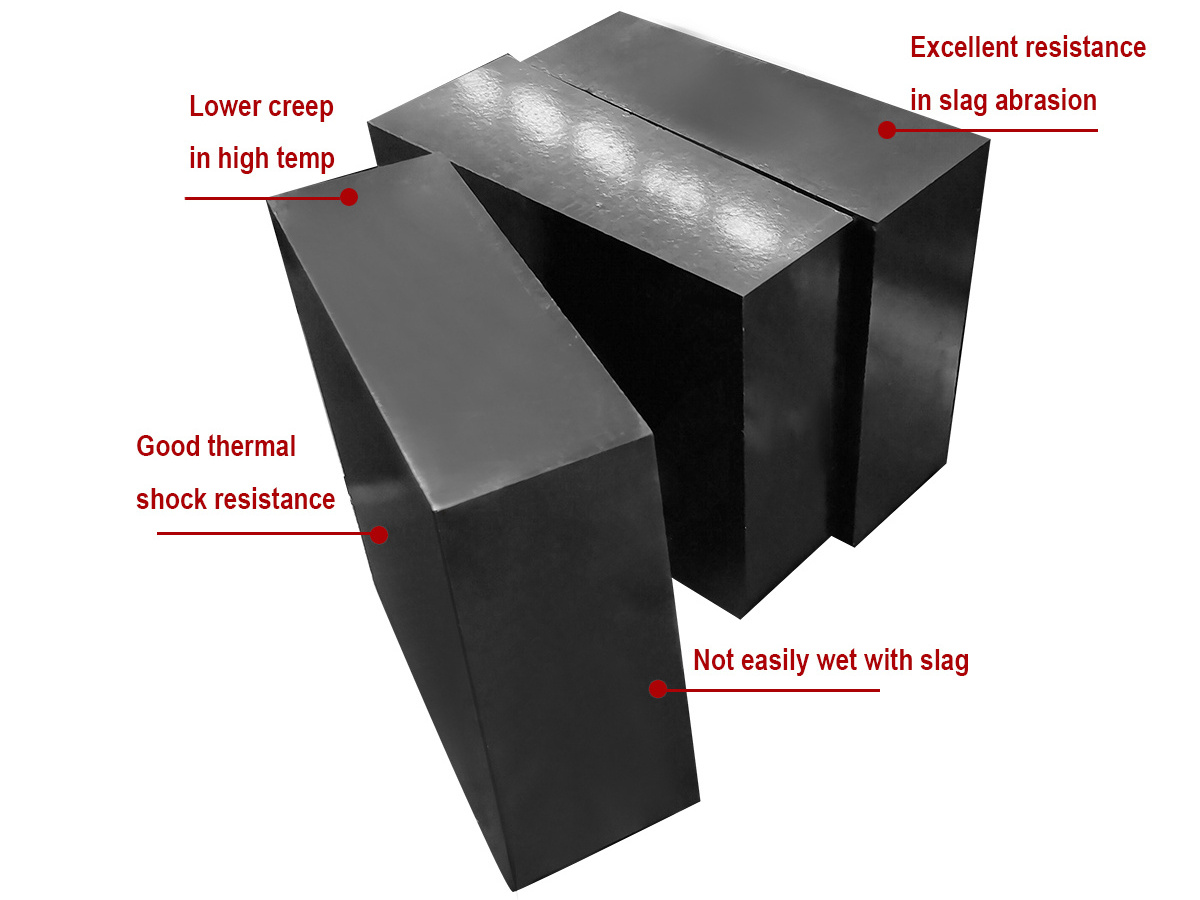

Magnesia Carbon brick is resin-bonded brick made from dead-burned or fused magnesia and graphite.Magnesia Carbon brick has good performance in thermal resistance, corrosion resistance and spalling resistance. Widely used in converters, EAFs, ladles and refining furnaces.

Magnesia Carbon brick is resin-bonded brick made from dead-burned or fused magnesia and graphite.Magnesia Carbon brick has good performance in thermal resistance, corrosion resistance and spalling resistance. Widely used in converters, EAFs, ladles and refining furnaces.

Product Paramenters

|

EAF

|

|

|

|

|

||||

|

Brand

|

ZTM-ZMT10A

|

ZTM-ZMT12A

|

ZTM-ZMT14A

|

ZTM-ZMT16A

|

||||

|

MgO (%)

|

≥80

|

≥78

|

≥76

|

≥74

|

||||

|

C (%)

|

10~12

|

12~14

|

14~16

|

16~18

|

||||

|

AP (%)

|

≤3.0

|

≤3.0

|

≤3.0

|

≤3.0

|

||||

|

BD (g.cm-3)

|

≥3.00

|

≥2.98

|

≥2.98

|

≥2.98

|

||||

|

CCS (MPa)

|

≥40

|

≥40

|

≥40

|

≥40

|

||||

|

HMOR (MPa)

(1450℃,30min) |

≥10

|

≥12

|

≥12

|

≥12

|

||||

|

Application

|

Used for the side wall.

|

Used for the slag line and hot spot.

|

|

|

||||

|

BOF

|

|

|

|

|

|

|||||

|

Brand

|

ZTM-ZMT10A

|

ZTM-ZMT12A

|

ZTM-ZMT14A

|

ZTM-ZMT16A

|

ZTM-ZMT16A

|

|||||

|

MgO (%)

|

≥80

|

≥78

|

≥76

|

≥74

|

≥72

|

|||||

|

C (%)

|

10

|

12

|

14

|

16

|

18

|

|||||

|

AP (%)

|

≤3.0

|

≤3.0

|

≤3.0

|

≤3.0

|

≤3.0

|

|||||

|

BD (g.cm-3)

|

≥3.10

|

≥3.10

|

≥3.03

|

≥3.00

|

≥2.97

|

|||||

|

CCS (MPa)

|

≥40

|

≥40

|

≥40

|

≥35

|

≥35

|

|||||

|

HMOR (MPa)

(1450℃,30min) |

≥8

|

≥8

|

≥10

|

≥10

|

≥10

|

|||||

|

Application

|

Used for the furnace crown and the bottom.

|

|

Used for the trunnion,tapping and molten pool.

|

|

|

|||||

1. Comprehensive Solutions:

* We provide a stable supply of high-quality refractory materials, ensuring uninterrupted production.

* Our one-stop procurement streamlines the process, offering a complete set of products tailored to your needs.

* Benefit from comprehensive technical support , including on-site inspections and guidance by our expert engineers.

2. Dedicated Service and Customization:

* Our dedicated engineers and after-sales team are stationed at your factory, ensuring seamless integration of our products.

* We customize designs and adjustments to meet your specific requirements, guaranteeing product quality that exceeds industry

standards.

3. Continuous Improvement:

* We continuously enhance product quality and technical expertise to adapt to your unique steelmaking environment.

* Our commitment to improvement ensures that we meet and exceed your expectations, every step of the way.

* We provide a stable supply of high-quality refractory materials, ensuring uninterrupted production.

* Our one-stop procurement streamlines the process, offering a complete set of products tailored to your needs.

* Benefit from comprehensive technical support , including on-site inspections and guidance by our expert engineers.

2. Dedicated Service and Customization:

* Our dedicated engineers and after-sales team are stationed at your factory, ensuring seamless integration of our products.

* We customize designs and adjustments to meet your specific requirements, guaranteeing product quality that exceeds industry

standards.

3. Continuous Improvement:

* We continuously enhance product quality and technical expertise to adapt to your unique steelmaking environment.

* Our commitment to improvement ensures that we meet and exceed your expectations, every step of the way.

Product Application

Magnesia Carbon Bricks for Sale is widely used in converters, EAFs, steel ladles, furnace wall and working lining of all kinds of furnace.

No matter where you're located, our steel refractories company is equipped to provide on-site services, solutions, projects, and supervision.

Hot Searches